12

3M

™

Steri-Vac

™

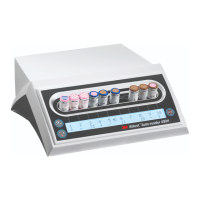

Sterilizer /Aerator GSSeries – Operator’sManual

9.2. Room and InstallationRequirements

DANGER: To reduce the risks associated with exposure to ethyleneoxide,

ensure a minimum of ten (10) air exchanges per hour (ACHs) for the room in which the 3M™Steri-Vac™ Sterilizer/Aerator GS Series is installed.

Location Do not place the sterilizer or ethylene oxide (EO) cartridges in an area of possible ignition sources. ONLY USEINDOORS.

Room Size Greater than 30m

3

(1,000ft

3

)

Spacing

Allow 51cm (20inches) of clearance space at the top, rear, and sides of the sterilizer for maintenance and service and a minimum of 10cm (4inches) from the rear wall for

single door units. Ensure sufficientspace

Ventilation Negative pressure with a minimum of ten (10) air exchanges per hour. The ventilation system should be non-recirculating anddedicated.

Air Flow Air flow washes the entire room. Air movement is away from the sterilizer Operator. See Figure2.

Exhaust

ACCEPTABLE

Exhaust

or

Sterilizer

Air flow washes entire room.

Air movement is away from operator.

Intake

Exhaust

Intake

UNACCEPTABLE

Sterilizer

“Dead” Air Space

Air movement is toward operator

and “dead” air spaces can form.

Figure2.

Acceptable and Unacceptable Installation AirFlow

Loading...

Loading...