66

3M

™

Steri‑Vac

™

Sterilizer / Aerator GSXSeries – Operator’sManual

13.3. Overview of GSX Series Ethylene Oxide (EO) SterilizationCycle

13.3.1. Cycle Stages andDescriptions

3M™Steri‑Vac™ Sterilizer/Aerator GSX Series ethylene oxide (EO) sterilization cycles consist of ten stages. After the sterilization cycle is complete, an aeration cycle is required to remove any

residual EO from the medical devices per the manufacturers’ instructions for use(IFUs).

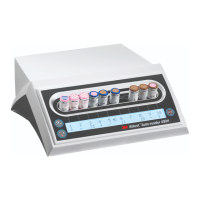

While a sterilization cycle is running, icons on the bottom of the display screen indicate the current stage of the cycle (both with a white box around them and in the stage indicator). Each icon,

and the corresponding sterilization cycle stage, is describedbelow.

Stage 1:Preheat

The temperature of the sterilizer chamber is controlled to attain the pre‑set

operatingtemperature.

Stage 2: AirRemoval

A vacuum is created to remove air from the chamber and load. The vacuum rate is dependent

upon the nature of the sterilization load, environmental conditions and preprogrammed

vacuumrate.

Stage 3: ChamberTest

The Chamber Test measures the integrity of the sealed system and chamber. The test is carried

out prior to the start of both the EO Injection stage and Conditioning stage at a pre‑set vacuum

level. Once the vacuum level is obtained, the pressure rise in the chamber is monitored for the

set point duration, after an appropriate equilibration time that allows for pressure stabilization.

During this period, the final chamber pressure measurement minus the initial chamber

pressure measurement must be less than 18mBar (1.8kPa).

Stage 4:Conditioning

The Conditioning stage involves treatment of the product load within the sterilization cycle, prior

to EO admission, in order to attain a predetermined temperature and relative humidity. This part

of the sterilization cycle is carried out completely under vacuum in the GSX Seriessterilizer.

Stage 5: EOInjection

When the 3M™Steri‑Gas™ EO Gas Cartridge is punctured, EO is vaporized and pulled into

the chamber by the pre‑injection chamber vacuumlevel.

Stage 6: EOExposure

EO Exposure is the pre‑set time period between the end of EO Injection and the beginning of

EO Removal when EO is sterilizing theload.

Stage 7: EORemoval

During this stage, EO is removed from the sterilizer chamber but not necessarily removed from

the sterilizationload.

Stage 8:Flushing

During the Flushing stage of the sterilization cycle, the EO is removed from the load and the

open chamber space of the sterilizationchamber.

Stage 9:Aeration

During Aeration, EO desorbs from the product load and devices until predetermined levels of

EO are reached. Aeration in the GSX Series sterilizer begins automatically after the sterilization

cycle is complete. Aeration duration is based on the selection made by the Operator, either a

specific time or continuousaeration.

[No Icon] Stage 10: Air AdmissionStage

Filtered air is admitted into the chamber to allow the chamber pressure to equilibrate with

ambient pressure. An “Opening door…” message will appear on the display screen during the

Air Admissionstage.

Loading...

Loading...