34

MAINTENANCEMAINTENANCE

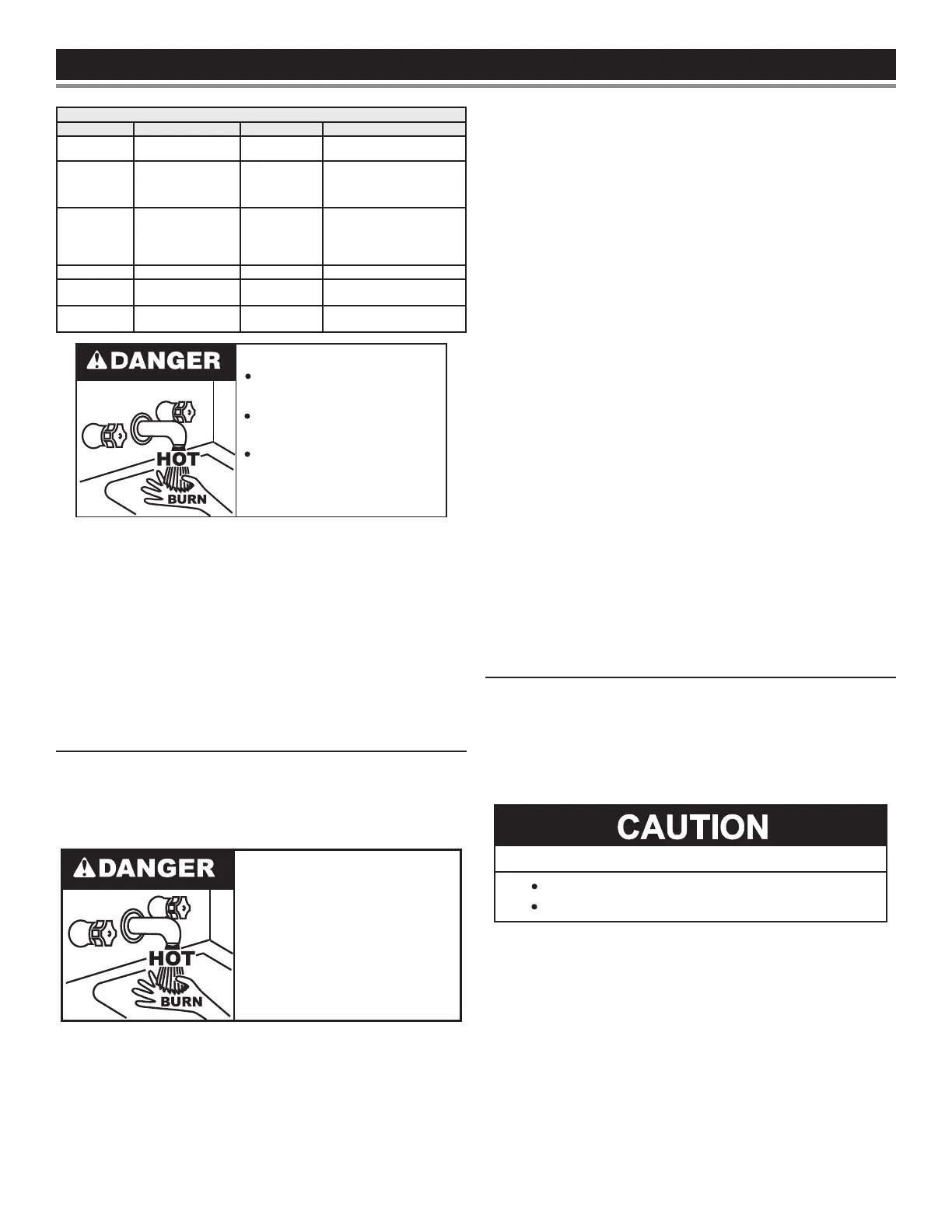

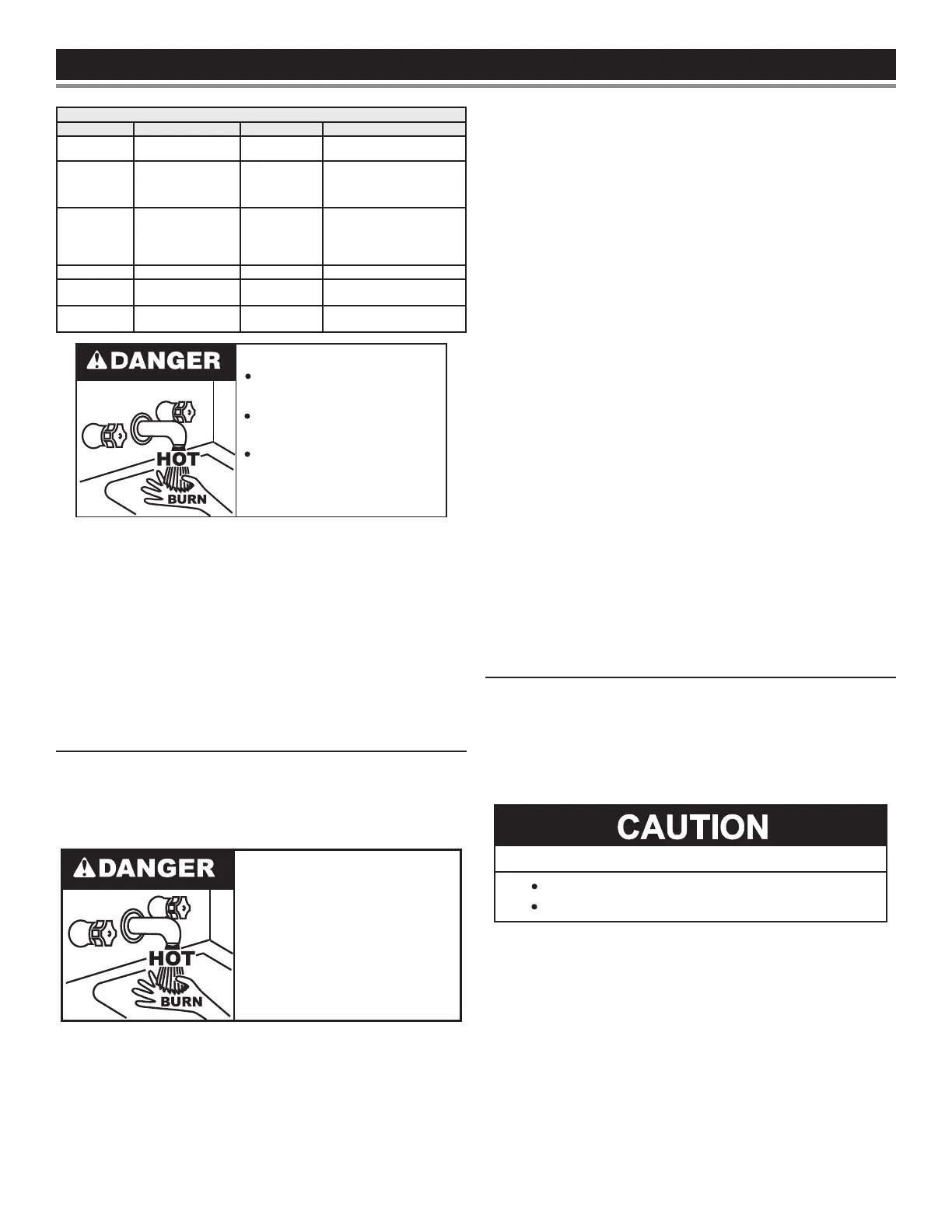

Table 17. Maintenance Schedule

Component Operation Interval Reference

Tank Drain and Flush

Every 6

Months

See

Draining and Flushing.

Tank

Lime Scale Re-

moval

(Water Less Than

25 Grains Hard)

Not Required N/A

Tank

Lime Scale Re-

moval

(Water Greater

Than 25 Grains

Hard)

Annually

See

Lime Scale Removal

(page

35).

Moving Parts Lubrication Not Required N/A

Powered

Anodes

Inspection/

Cleaning

Annually

See

Anode Maintenance

(page

34).

T&P Valve Test Operation Semi Annually

See

Temperature-Pressure Relief

Valve Test

(page 36).

Burn hazard.

Hot water discharge.

Keep clear of Temperature-

Pressure Relief Valve

discharge outlet.

Periodically the drain valve should be opened and the water allowed

to run until it ows clean. This will help to prevent sediment buildup

in the tank bottom.

Periodically check the temperature and pressure relief valve to

ensure that it is in operating condition. Lift the lever at the top of the

valve several times until the valve seats properly and operates freely.

Water heater maintenance includes periodic tank ushing and

cleaning, and removal of lime scale from the heating element.

The heater tank is equipped with an anode rod to aid in corrosion

control.

DRAINING AND FLUSHING

It is recommended that the water heater storage tank be drained and

ushed every 6 months to reduce sediment buildup. The water heater

should be drained if being shut down during freezing temperatures.

See Figure 1 (page 7) for the location of the water heater

components described below.

• Burn hazard.

• Hot water discharge.

• Keep hands clear of drain

valve discharge.

DRAINING THE WATER HEATER STORAGE TANK

1. Turn o the electrical supply to the water heater.

2. Ensure the cold water inlet valve is open.

3. Open a nearby hot water faucet and let the water run until the

water is no longer hot.

4. Close the cold water inlet valve to the water heater.

5. Connect a hose to the water heater drain valve and terminate it

to an adequate drain.

6. Open the water heater drain valve and allow all the water to drain

from the storage tank.

7. Close the water heater drain valve when all water in the storage

tank has drained.

8. Close the hot water faucet opened in Step 3.

9. If the water heater is going to be shut down for an extended

period, the drain valve should be left open.

FLUSHING THE WATER HEATER

1. Turn o the electrical supply to the water heater at the breaker

or disconnect switch.

2. Ensure the cold water inlet valve is open.

3. Open a nearby hot water faucet and let the water run until the

water is no longer hot. Then close the hot water faucet.

4. Connect a hose to the water heater drain valve and terminate it

to an adequate drain.

5. Ensure the drain hose is secured before and during the entire

ushing procedure. Flushing is performed with system water

pressure applied to the water heater.

6. Open the water heater drain valve to ush the storage tank.

7. Flush the water heater storage tank to remove sediment and

allow the water to ow until it runs clean.

8. Close the water heater drain valve when ushing is completed.

9. Remove the drain hose.

10. Fill the water heater. See

Filling the Water Heater

(page 17).

11. Turn on the electrical supply to the water heater.

12. Place the water heater back in operation. Allow the water heater to

complete several heating cycles to ensure it is operating properly.

ANODE MAINTENANCE

Each water heater contains at least one anode rod, which will slowly

deplete (due to electrolysis) prolonging the life of the water heater

by protecting the glass-lined tank from corrosion. Adverse water

quality, hotter water temperatures, high hot water usage, hydronic

heating devices, and water softening methods can increase the rate

of anode rod depletion. Once the anode rod is depleted, the tank

will start to corrode, eventually developing a leak.

Avoid damage.

Property Damage Hazard

Inspection and replacement of anode rod required.

Certain water conditions will cause a reaction between the anode

rod and the water. The most common complaint associated with

the anode rod is a “rotten egg smell” produced from the presence

of hydrogen sulde gas dissolved in the water.

Important: Do not remove this rod permanently as it will

void any warranties. A special anode rod may be

available if water odor or discoloration occurs.

Note: This rod may reduce but not eliminate water odor

problems. The water supply system may require special

ltration equipment from a water conditioning company

to successfully eliminate all water odor problems.

Articially softened water is exceedingly corrosive because the

process substitutes sodium ions for magnesium and calcium ions.

Printed on 5/6/2022 7:17 AM CT

Loading...

Loading...