Planning the electrical installation

41

* manufactured before 1.1.1998

** For motors manufactured before 1.1.1998, check for additional instructions with the motor manufacturer.

*** If the intermediate DC circuit voltage of the drive will be increased from the nominal level by resistor braking or

by the IGBT supply unit control program (parameter selectable function), check with the motor manufacturer if

additional output filters are needed in the applied drive operation range.

Note 1: The abbreviations used in the table are defined below.

Note 2: Explosion-safe (EX) motors

The motor manufacturer should be consulted regarding the construction of the motor insulation and

additional requirements for explosion-safe (EX) motors.

Note 3: High-output motors and IP 23 motors

For motors with higher rated output than what is stated for the particular frame size in EN 50347 (2001)

and for IP 23 motors, the requirements of ABB random-wound motor series M3AA, M3AP, M3BP are

given below. For other motor types, see the Requirements table above. Apply the requirements of

range 100 kW < P

N

< 350 kW to motors with P

N

< 100 kW. Apply the requirements of range P

N

>

350 kW to motors within the range 100 kW < P

N

< 350 kW. In other cases, consult the motor

manufacturer.

Note 4: HXR and AMA motors

All AMA machines (manufactured in Helsinki) for drive systems have form-wound windings. All HXR

machines manufactured in Helsinki starting 1.1.1998 have form-wound windings.

Note 5: ABB motors of types other than M2_, M3_, HX_ and AM_

Use the selection criteria given for non-ABB motors.

Note 6: Resistor braking of the drive

When the drive is in braking mode for a large part of its operation time, the intermediate circuit DC

voltage of the drive increases, the effect being similar to increasing the supply voltage by up to 20

percent. The voltage increase should be taken into consideration when determining the motor insulation

requirement.

Example:

Motor insulation requirement for a 400 V application must be selected as if the drive were

supplied with 480 V.

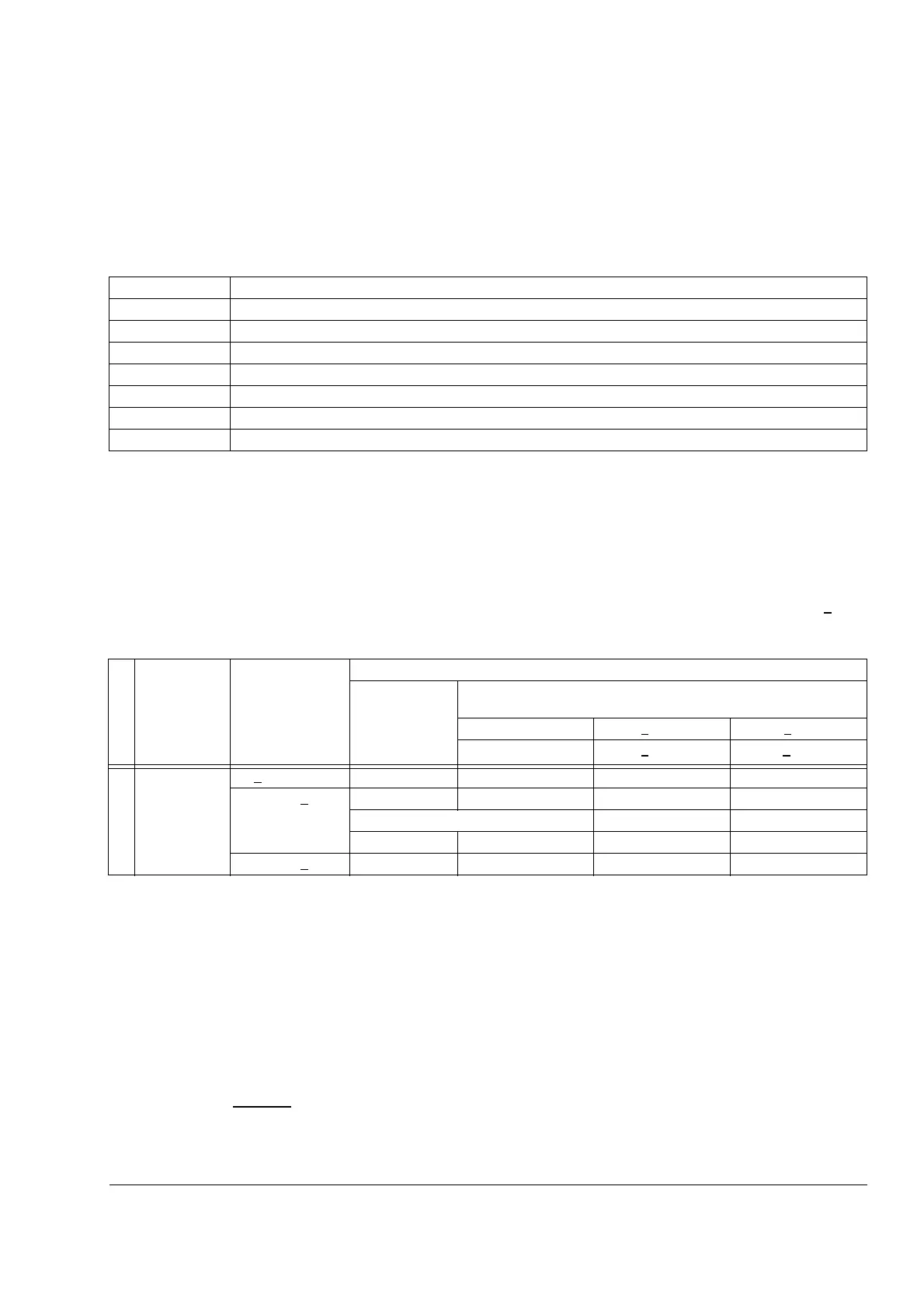

Abbreviation Definition

U

N

nominal voltage of the supply network

Û

LL

peak line-to-line voltage at motor terminals which the motor insulation must withstand

P

N

motor nominal power

du/dt du/dt filter at the output of the drive +E205

CMF common mode filter +E208

N N-end bearing: insulated motor non-driven end bearing

n.a. Motors of this power range are not available as standard units. Consult the motor manufacturer.

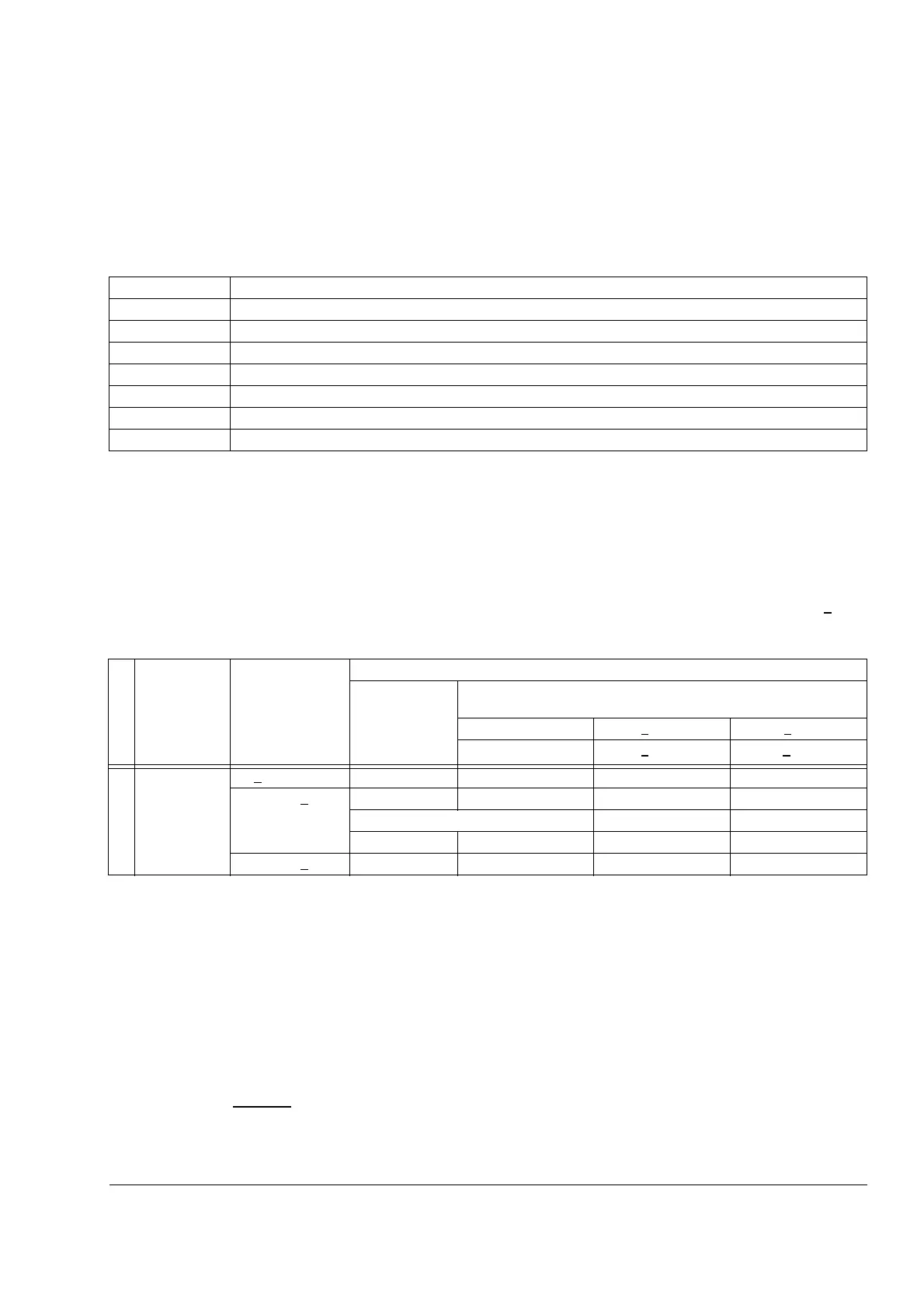

Manufacturer

Motor type Nominal mains

voltage (AC line

voltage)

Requirement for

Motor insulation

system

ABB du/dt filter, insulated N-end bearing and ABB common mode

filter

P

N

< 55 kW 55 kW < P

N

< 200 kW P

N

> 200 kW

P

N

< 74 HP 74 HP < P

N

< 268 HP P

N

> 268 HP

A

B

B

Random-

wound M3AA,

M3AP, M3BP

U

N

< 500 V Standard - + N + N + CMF

500 V < U

N

< 600 V Standard + du/dt + du/dt + N + du/dt + N + CMF

or

Reinforced - + N + N + CMF

600 V < U

N

< 690 V Reinforced + du/dt + du/dt + N + du/dt + N + CMF

Loading...

Loading...