Kunkle Safety and Relief Products

Tyco reserves the right to change product design and specifications KUKMC-0392

without notice. Copyright © 2002 by Tyco International Ltd. 8

Models 910, 911, 912, 913, 916, 917, 918, 919, 920, 921 and 927

Models 912, 913, 918, 919 ASME Section VIII, Steam/Air/Gas/ Liquid, ‘UV’ National Board Certified. Also available

for Vacuum Service

Service Recommendations for Resilient Seat/Seal Materials

Seat/Seal Materials

1

Service Recommendation

Air, Anhydrous Ammonia, Butane, Carbon Dioxide, Diesel Oil, Ethyl Chloride, Ethyl Ether, Freons #11

BUNA-N (-40° to 275°F) [-40° to 135°C] and 12, Fuel Oil, Gasoline, Helium, Hydrogen Sulphide, Kerosene, Lube Oil, Natural Gas, Nitrogen,

Oxygen (Gas), Propane, Propylene, Sulphur Dioxide, Vinyl Chloride

Acetone, Air, Amyl Alcohol, Aniline, Benzine, Butane, Carbon Disulphide, Carbon Tetrachloride

Dowtherm ‘A’ and ‘E’, Ethyl Chloride, Ethylene, Ethylene Glycol, Ethyl Alcohol, Gasoline, Hexane,

Viton

®

A (-10° to 406°F) [-23° to 208°C] Hydrogen Sulphide, Isobutyl Alcohol, JP - 4 Fuel, JP - 5 Fuel, Kerosene, Lube Oil, Natural Gas,

Naphtha, Nitrogen, Propane, Propylene, Propyl Alcohol, Sulphur Dioxide, Toluene, Trichloroethylene,

Turpentine, Water, Xylene

Silicone (-100° to 406°F) [-73° to 208°C] Air, Helium, Nitrogen, Oxygen (Gas)

Ethylene Propylene (-70° to 400°F) [-57° to 205°C] Steam, Hot Water

Neoprene (-45° to 300°F) [-43° to 149°C]

Air, Anhydrous Ammonia, Butane, Butyl Alcohol, Castor Oil Denatured Alcohol, Ethanol, Ethyl

Alcohol, Freons (12, 13, 14 and 22), Glycols, Natural Gas and Silicate Esters

Plain Lever

Threaded Cap

Packed Lever

Note

1. These recommendations are a guide only.

For the final selection of the proper material,

your experience with available elastomers of

various lading fluids should be considered.

Specifications

Model

2

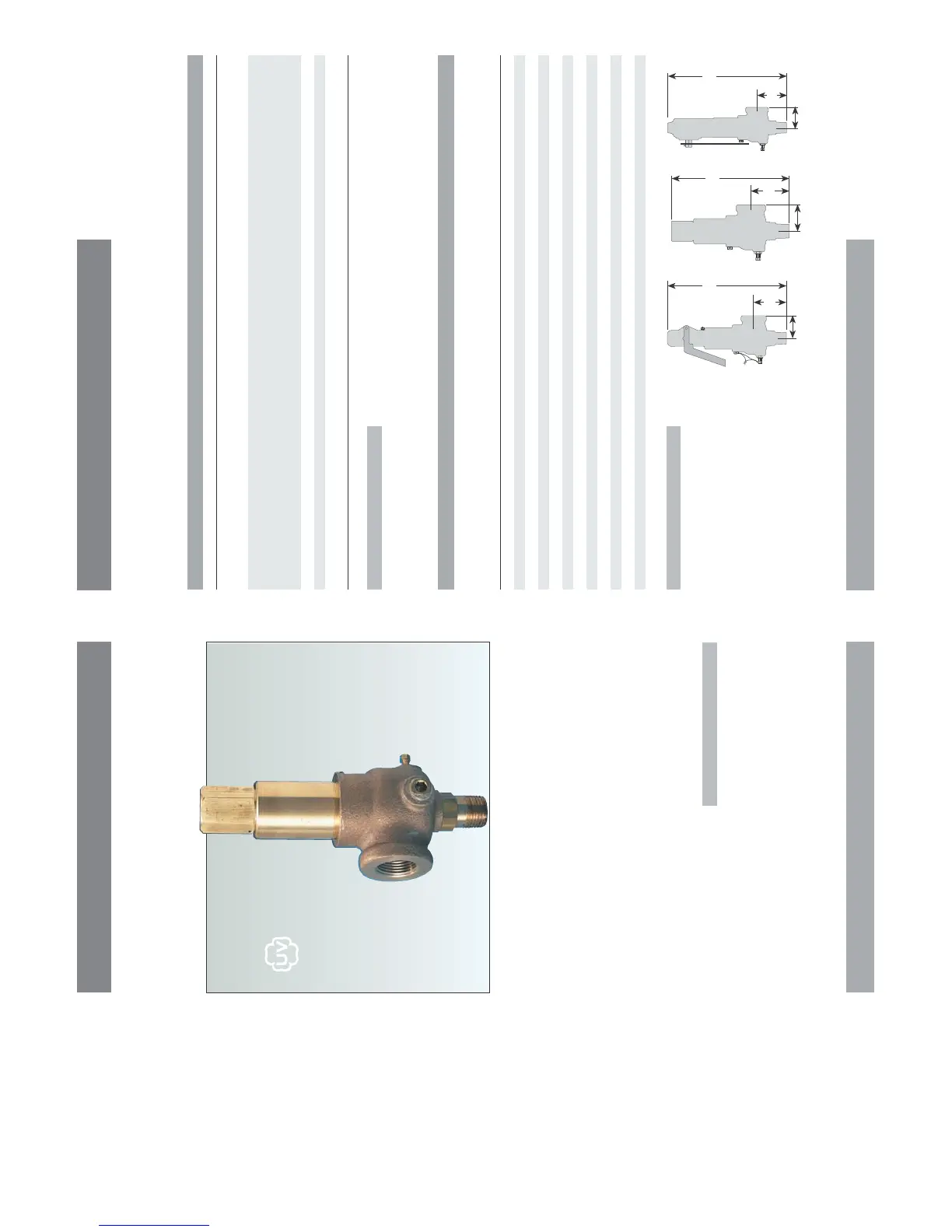

Orifice Connections Maximum Set Pressure ––-–––––––– Dimensions, in [mm] –––-–––––––– Approx.

Number ANSI Standard psig [barg] A B C C C Weight

Inlet Outlet 912-918

4

913-919

5

Plain Threaded Packed lb [kg]

Lever Cap Lever

9*BDC D

1

/2” [12.7]

3

/4” [19.0] 300 [20.7] 900 [62.1] 2

3

/8 [60] 1

5

/8 [41] 8

3

/8 [213] 7

1

/4 [184] 9 [229] 3 [1.4]

9*BDC

7

D

1

/2” [12.7] 1” [25.4] 300 [20.7] 900 [62.1] 2

3

/8 [60] 1

5

/8 [41] 8

3

/8 [213] 7

1

/4 [184] 9 [229] 3 [1.4]

9*BDD

3

D

3

/4” [19.0]

3

/4” [19.0] — — 900 [62.1] 2

3

/8 [60] 1

5

/8 [41] 8

3

/8 [213] 7

1

/4 [184] 9 [229] 3 [1.4]

9*BDE

3

D 1” [25.4] 1” [25.4] — — 900 [62.1] 2

5

/8 [67] 1

5

/8 [41] 8

5

/8 [219] 7

1

/2 [191] 9

1

/8 [232] 3 [1.4]

9*BED E

3

/4” [19.0] 1

1

/4” [31.8] 300 [20.7] 900 [62.1] 2

5

/8 [67] 2 [51] 8

3

/4 [222] 7

5

/8 [194] 9

3

/8 [238] 4 [1.8]

9*BEF

3

E1

1

/4” [31.8] 1

1

/4” [31.8] — — 900 [62.1] 3 [76] 2 [51] 9

1

/8 [232] 8 [203] 9

3

/4 [248] 4 [1.8]

9*BFE F 1” [25.4] 1

1

/2” [38.1] 300 [20.7] 600 [41.4] 2

7

/8 [73] 2

3

/8 [60] 9

7

/8 [251] 8

3

/4 [222] 10

1

/2 [267] 6 [2.7]

9*BFG

3

F1

1

/2” [38.1] 1

1

/2” [38.1] — — 600 [41.4] 3 [76] 2

3

/8 [60] 10 [254] 8

7

/8 [225] 10

5

/8 [270] 6 [2.7]

9*BGF G 1

1

/4” [31.8] 2” [50.8] 300 [20.7] 600 [41.4] 3

1

/4 [89] 2

5

/8 [67] 11

1

/4 [286] 10

1

/8 [257] 11

3

/4 [298] 8 [3.6]

9*BGH

3

G 2” [50.8] 2” [50.8] — — 600 [41.4] 3

1

/4 [89] 2

5

/8 [67] 11

1

/4 [286] 10

1

/8 [257] 11

3

/4 [298] 8 [3.6]

9*BHG H 1

1

/2” [38.1] 2

1

/2” [63.5] 300 [20.7] 500 [34.5] 3

1

/2 [89] 2

3

/4 [70] 13 [330] 11

1

/8 [283] 12

1

/2 [318] 11 [5.0]

9*BJH J

6

2” [50.8] 3” [76.2] 300 [20.7] 500 [34.5] 4 [102] 3

1

/4 [89] 14

1

/2 [368] 12

1

/2 [318] 15

1

/8 [384] 15 [6.8]

Notes

1. Maximum temperature controlled by resilient

seat/seal material.

2. Replace asterisk with desired Model Number.

Data applicable to all models.

3. Available with SS trim only.

4. Maximum pressure on steam is 250 psig.

5. Maximum pressure on steam is 300 psig.

6. For C dimensions: pressures above 200 psig

[14 barg] add 1.25-inch [31.8 mm] to the

overall height.

7. Special variation required. Consult factory.

A

C

B

A

C

B

A

C

B

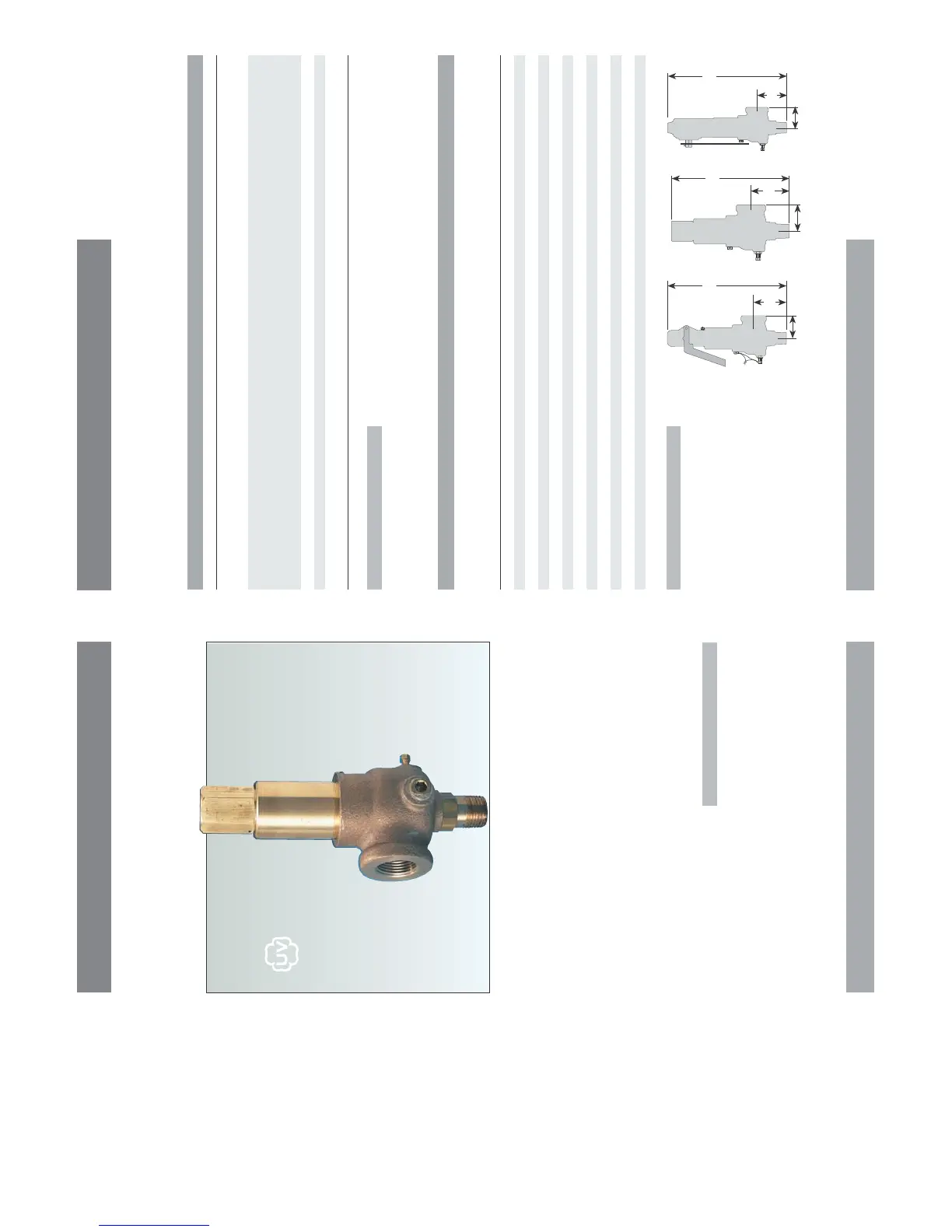

Models 912, 913, 918 and 919 ASME Section VIII, Air/Steam/Gas/Liquid,

‘UV’ National Board Certified. Also available for Vacuum Service

Model 912

Kunkle Safety and Relief Products

Tyco reserves the right to change product design and specifications KUKMC-0392

without notice. Copyright © 2002 by Tyco International Ltd. 7

Models 910, 911, 912, 913, 916, 917, 918, 919, 920, 921 and 927

Features

• Available with soft seat.

• Threaded cap is standard (back pressure

tight).

• Hex on valve nozzle provides for easy

installation.

• Single control ring offers easy

adjustability of blowdown.

• Pivoting disc design corrects

misalignment and offers exceptional

performance.

• Guide to nozzle ratio reduces friction.

• Full nozzle design for optimum flow

performance.

• Threaded side outlet for piped off

discharge to eliminate fugitive emissions.

Options

• Threaded cap. (Variation 01)

• Threaded cap with gag. (Variation 02)

• Plain lever. (Variation 03)

• Plain lever with gag. (Variation 04)

• Plain lever with vibration dampener.

(Variation 05)

• Packed lever. (Variation 06)

• Packed lever with gag. (Variation 07)

Model Descriptions

Model 912: Full nozzle design. SS warn ring

and disc with brass/bronze base. Bronze/

brass body and bonnet.

Model 913: Full nozzle design. Bronze/

brass body and bonnet. 316 SS trim (base,

disc and disc holder).

Model 918: Same as Model 912 except

resilient seat/seal. Superior ‘leak-free’

performance.

Model 919: Same as Model 913 except

resilient seat/seal. Superior ‘leak-free’

performance. Bronze body and bonnet.

316 SS trim (base, disc and disc holder).

Pressure and Temperature Limits

Models 912, 918: – Steam

3 to 250 psig [-0.2 to 17 barg]

1

-320° to 406°F [-195° to 208°C]

Models 913, 919: – Steam

3 to 300 psig [-0.2 to 17 barg]

1

-320° to 425°F [-195° to 219°C]

Models 912, 918: – Air/Gas/Liquid

3 to 300 psig [-0.2 to 21 barg]

-320° to 406°F [-195° to 208°C]

Models 913, 919: – Air/Gas/Liquid

3 to 900 psig [-0.2 to 62 barg]

-320° to 425°F [-195° to 219°C]

Vacuum – 6- through 29-inch HG

[200 through 1000 mbarg] – 300°F [149°C]

Maximum back pressure 50 psig [3 barg] -

threaded cap and packed lever

Note

1. ASME standard valves for air or steam

service must have lift lever. For steam boilers

and generators.

Applications

• Air/gas compressors - intercoolers -

aftercoolers.

• Liquid filled pressure vessels/systems -

ASME Section VIII (UV).

• Pressure vessels - containing gas, air,

liquid or steam. Including tanks and

receivers.

• Vacuum systems including pumps, tanks

and equipment.

• Optional materials for low temperature -

cryogenic applications.

• Oil/gas separators.

• Overpressure relief and protection

of pumps, tanks, lines and hydraulic

systems.

• By-pass relief or pressure regulation.

Loading...

Loading...