Vacuum Breakers - page 2

SERIES VB8 VACUUM BREAKERS

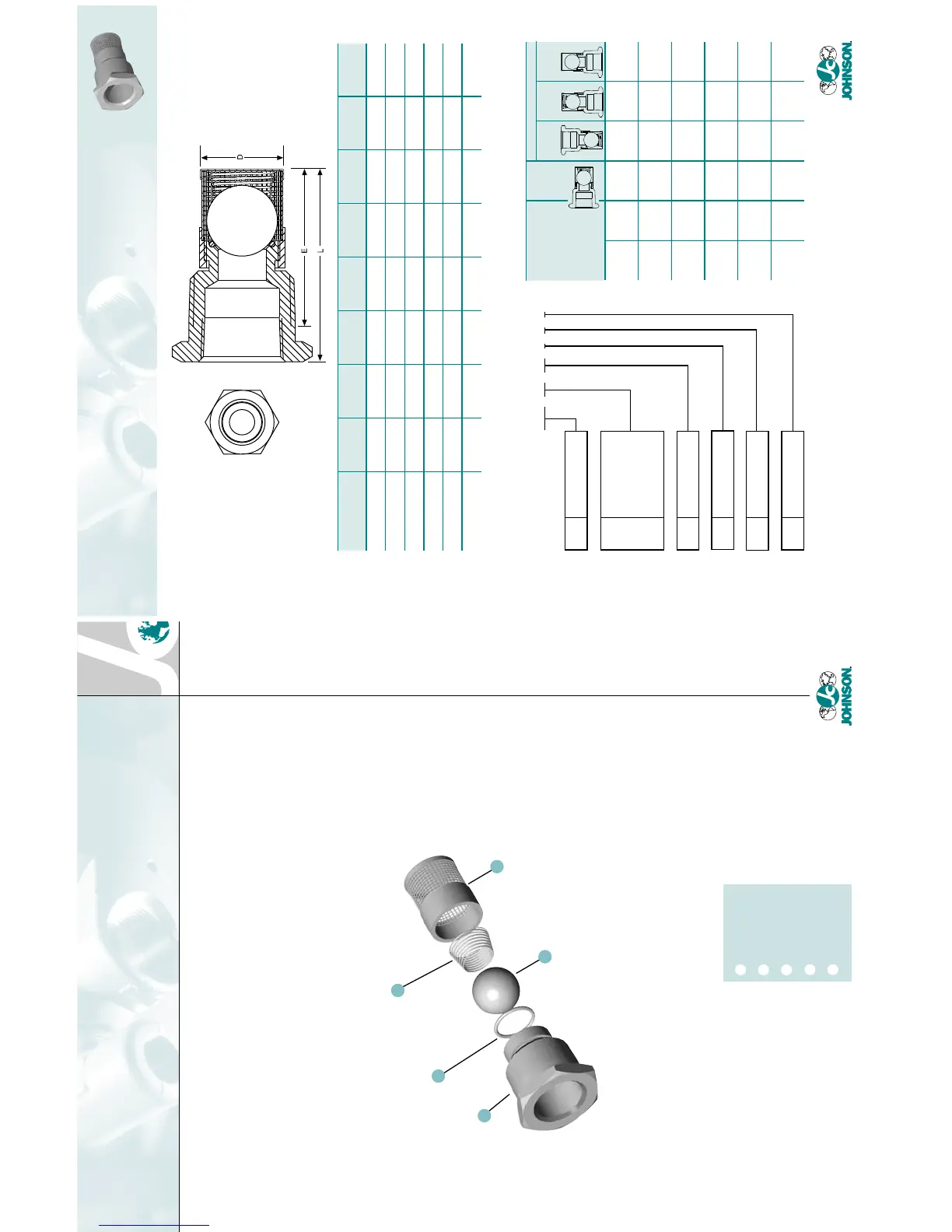

Catalog Number

VB8-38-BR-P-S-E

Pipe Thread

Size

20.3

1. 4 9

0.73

Outlet Pipe

Size

Total Length

“L”

Engaged

Length “E”

O.D. of Tube

“D”

Hex Body Size

Diameter of

Orifice

Diameter of

Ball

10.0

0.73

0.36

In. H

2

0

In. Hg

PSI

VB8-151

1-1/2”

4.9

0.36

0.18

7. 9

0.58

0.29

21.0

1. 5 4

0.76

10. 5

0.7 7

0.38

In. H

2

0

In. Hg

PSI

VB8-126

1-1/4”

7. 1

0.52

0.26

6.9

0.51

0.25

19.5

1. 4 3

0.70

10.0

0.73

0.36

In. H

2

0

In. Hg

PSI

VB8-101

1”

5.9

0.43

0.21

6.6

0.48

0.24

25.0

1.8 4

0.90

15.3

1.13

0.55

In. H

2

0

In. Hg

PSI

VB8-76

3/4”

15.0

1.10

0.54

5.1

0.37

0.18

18. 0

1.3 2

0.65

9.3

0.68

0.34

In. H

2

0

In. Hg

PSI

VB8-51

1/2”

10.6

0.78

0.38

4.4

0.32

0.16

10. 5

0.7 7

0.38

7. 0

0.51

0.25

In. H

2

0

In. Hg

PSI

VB8-38

3/8”

4.3

0.32

0.16

3.5

0.26

0.13

Horizontal

Top

Outlet

Bottom

Outlet

No

Spring

VB8-51-BR-P-S-E

VB8-76-BR-P-S-E

VB8-101-BR-P-S-E

VB8-126-BR-P-S-E

VB8-151-BR-P-S-E

VB8–38 –BR –P–S–E

VB8

Vacuum Breakers

E = EPR

(Specify alternate by name)

S = Stainless Steel

P = Plain

T = Threaded

BR = Brass

SS = Stainless Steel

38 = 3/8”

51 = 1/2”

76 = 3/4”

101 = 1 ”

126= 1-1/4”

151= 1-1/2”

Dimensions are in inches and for reference only.

Certified drawings are available on request.

Vertical

3/8

1/ 2

3/4

1

1-1/ 4

1-1/ 2

1/ 4

3/8

1/ 2

3/4

1

1-1/ 4

1-1/ 2

1-3/4

2-1/8

2-3/8

2-15/16

3-1/16

1-1/ 8

1-3/8

1-5/8

1-7/ 8

2-5/16

2-1/2

9/16

11 /1 6

13 /16

1-1/16

1-5/16

1-9/16

3/4

1

1-1/ 4

1-1/ 2

1-3/4

2

1/ 4

9/32

13/32

19/32

3/4

7/ 8

3/8

1/ 2

5/8

7/ 8

1-1/16

1-3/16

Vacuum Required to Open

Series

Size

Body

Outlet

Ball

Seal

Explanation of Catalog Numbers

Note: Stainless Steel Ball was used to arrive at all figures. Values

given are averages of test results and may vary slightly.

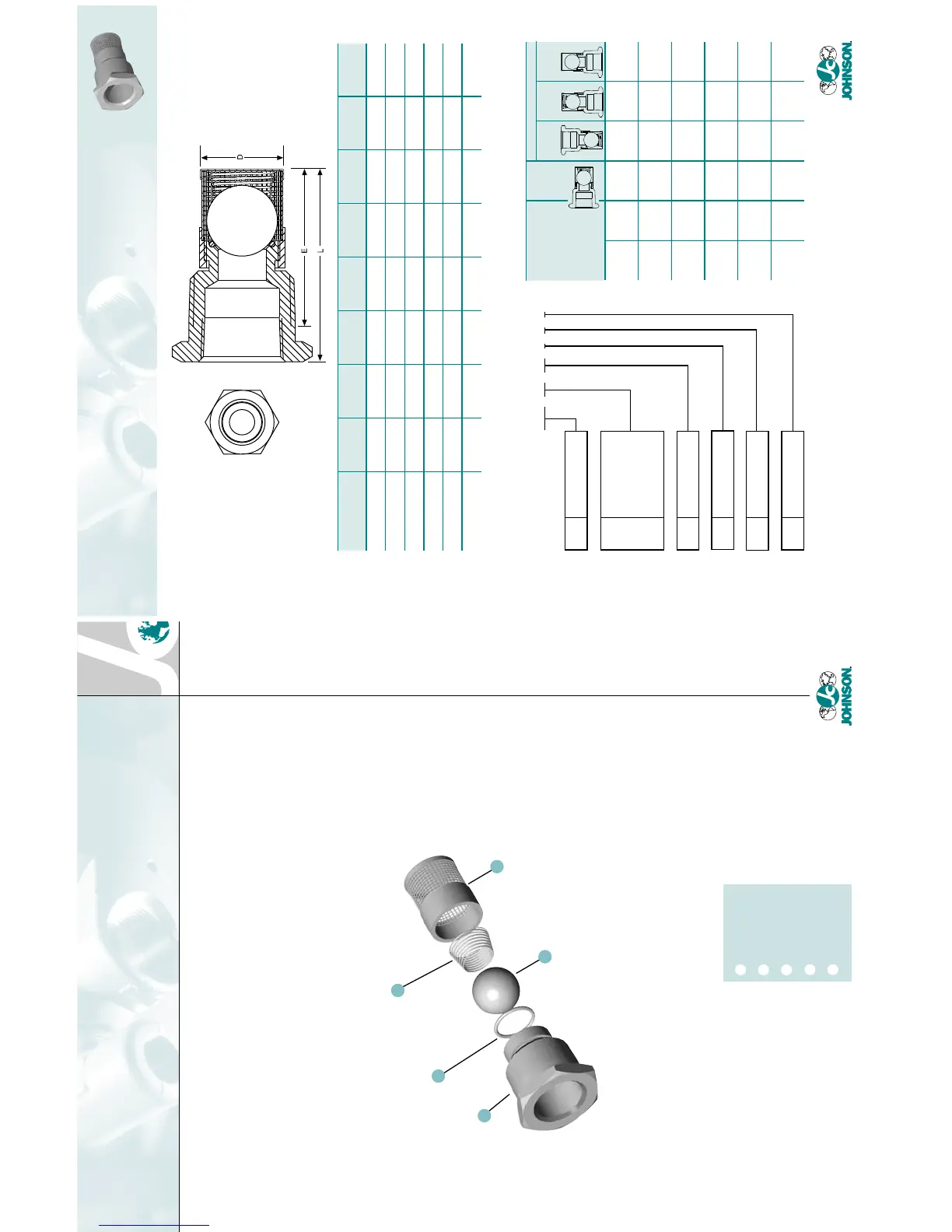

VACUUM BREAKERS

OPERATING

PARAMETERS

Temperature

Up to 365°F

Pressure

Up to 300 psig

Note: Maximum

limits vary in rela-

tion to changes in

pressure, and tem-

perature. Consult

Johnson for safe

limitations under

your specific appli-

cation conditions.

Assembly dimen-

sions are +/- 1/8”.

Johnson Vacuum Breakers provide a simple, dependable way to relieve

unwanted vacuum which may develop in a closed vessel or pipeline. They can

be used to prevent contamination from back siphonage in fluid handling sys-

tems, and to protect equipment against collapse or implosion. They combine

tight closing with instant response, provide large air venting capacity, and are

designed for easy installation and long service life.

2

5

4

1

3

1

Body

Retainer Tube

Ball

O-Ring

Spring

2

3

4

5

Loading...

Loading...