14

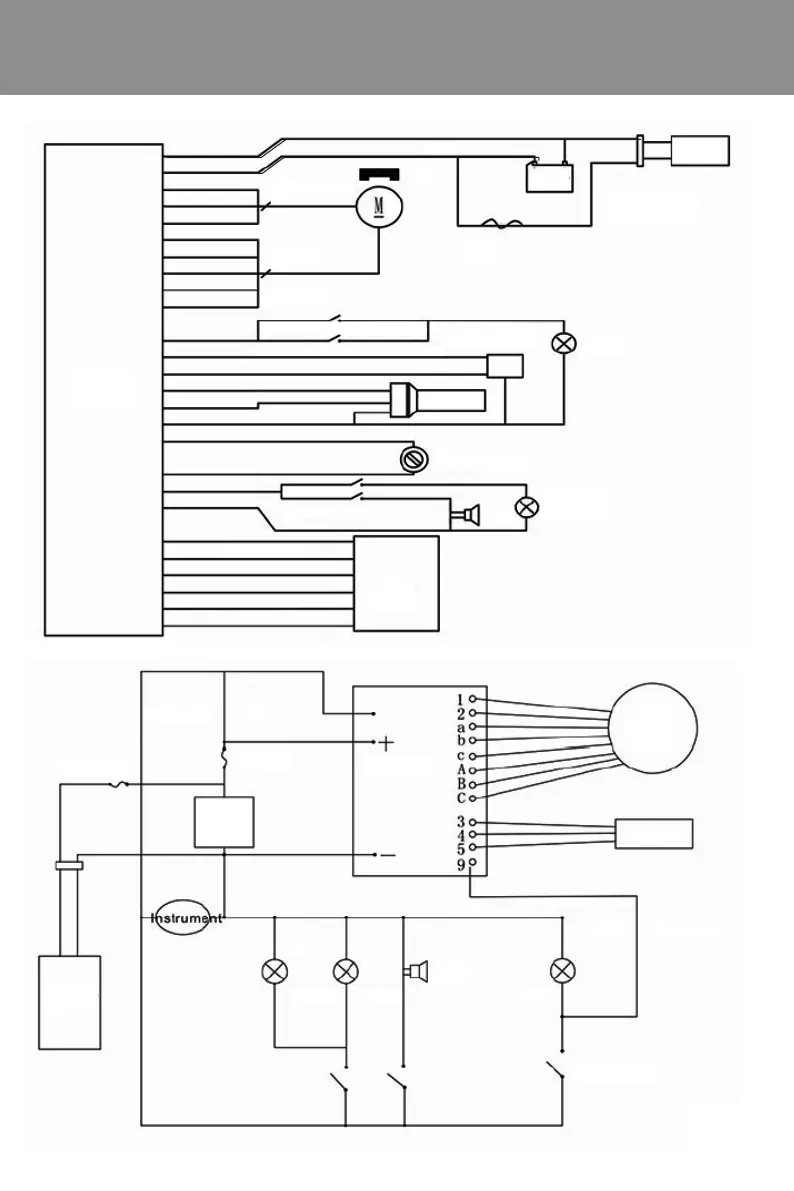

Electrical schematic diagram

II.Chain adjustment (see figure 4)

1.Loosen the rear axle left and right fastening nuts, adjust the chain regulator, move the rear

wheels back and forth, and tighten the tightness of the chain so that the sag in the middle of the

chain is 10-15mm.At this time, the tightness of the chain should be suitable for go slick, no

abnormal sound.

2.Keep the center surface of the rear wheel basically in the center surface of the frame, and tighten

the rear axle left and right fastening nuts. (Recommended torque is not less than 30N.m)

III.Front wheel disassembly (see Figure 5)

1.Loosen the left and rear fastening thread of the front axle, remove the nut, remove the front

axle, and remove the front wheel.

2.When assembling, align the center hole of the front wheel with the double arm hole of the

hydraulic front fork, penetrate the front axle into the hole, and tighten the left and right fastening

nuts of the front axle clock wise. After installation, rotate the front wheel, and there shall be no

stuck or loose phenomenon. (The recommended torque is not less than 18N. m)

IV.Rear wheel disassembly (see Figure 6)

1.Pull the motor cable off the connector, turn the car body over(note: Do not touch the handlebar,

head cover, toolbox parts), rotate the rear axle nut, rear brake positioning nut and brake cable in

the counterclockwise direction, unpack the chain joint, and then remove the rear wheel in the

direction of the opening.

Power negative P+

Motor line

Motor Hall

Front brakes handle power-off switch

Rear brake handle power-off switch

three-way switch

Transfer handle

Headlight switch

speaker switch

Anti-theft

device+

Power supply

electric door lock

Charger

Rear Light

dipped

headlight

Horn

brake lamp

Brake broken wire

Speeder

Contraller

30A fuse

Batter

M

Brake handle

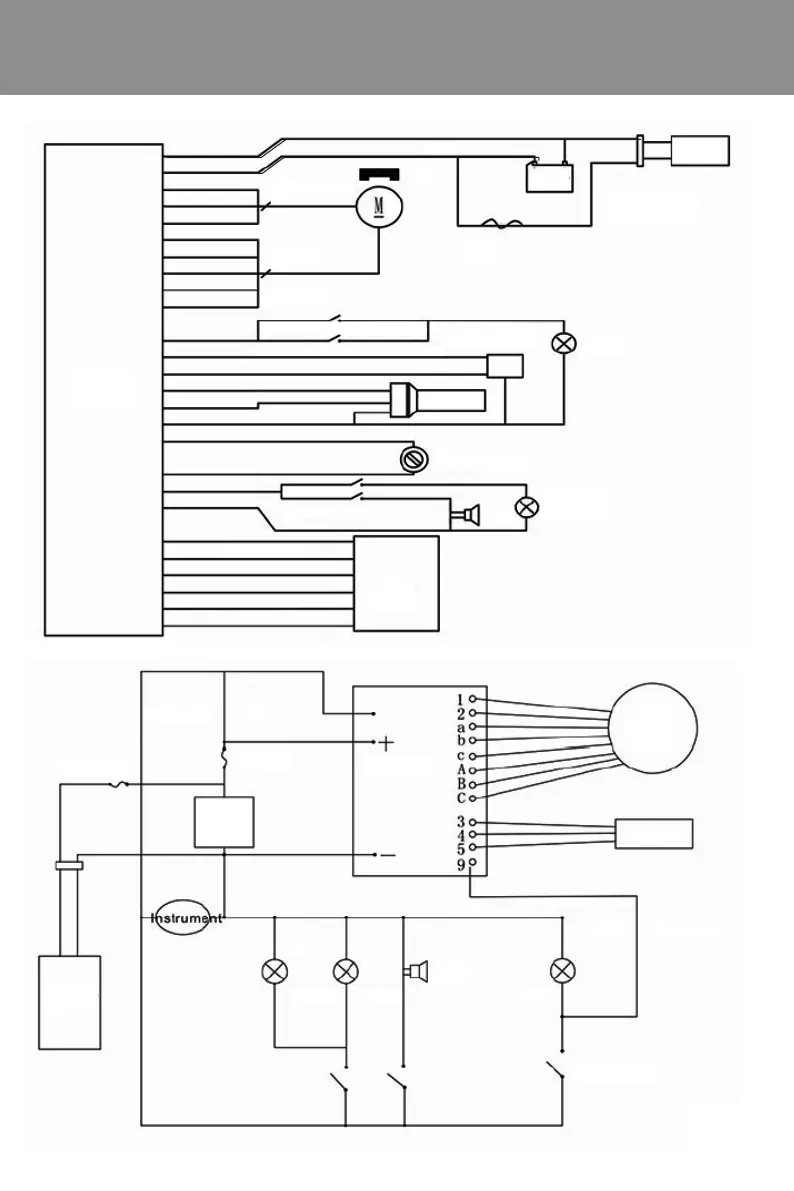

+

-

ACC

A3

w

F5

electric door lack

Headlight

Taillight

Fuse

Fuse

Battery

Charger

charging interface

5A

Controll

Loading...

Loading...