24

Step Three:

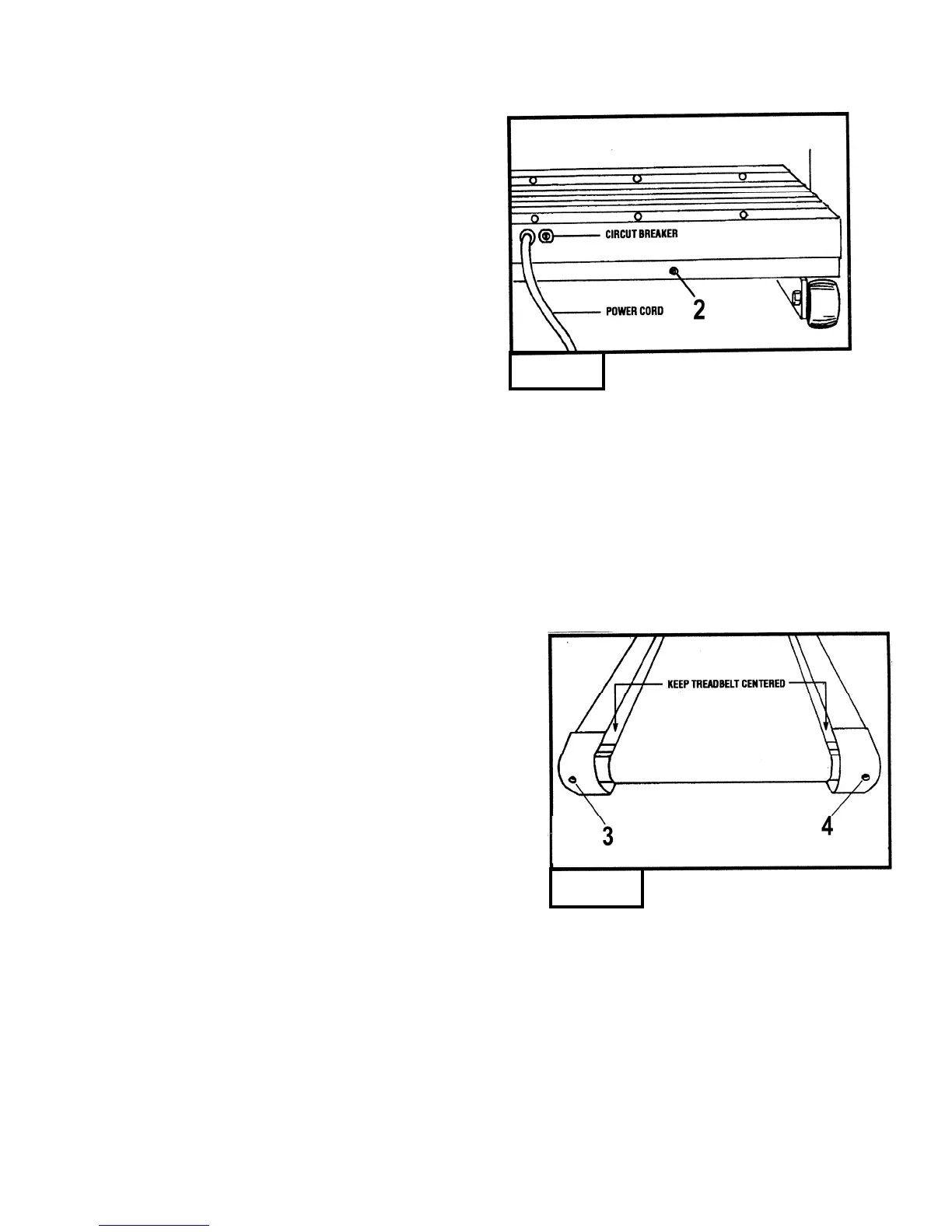

Locate the drive belt adjustment screw (2) in the lower

front end of the treadmill. Insert the allen wrench into the drive

belt adjustment screw. Turn the screw 1/2 turn clockwise.

Step Four:

Complete the adjustment by tightening the four motor mount

screws (1).

Step Five:

Walk on the treadmill to determine if the slippage is decreased

or eliminated.

Step Six:

If no improvement is observed, the hesitation may be caused

by a loose tread belt - see "Tread belt tension adjustment" below.

If improvement is noticed but slippage is still present, repeat the

procedure and test again. If you tighten the drive belt adjustment

screw 1 1/2 turns and there is still hesitation (slippage) contact

your local PaceMaster dealer. Tightening the drive belt

adjustment screw more than 1 1/2 turns can result in bearing

damage to the motor and/or drive roller.

Tread belt tension adjustment

Step One:

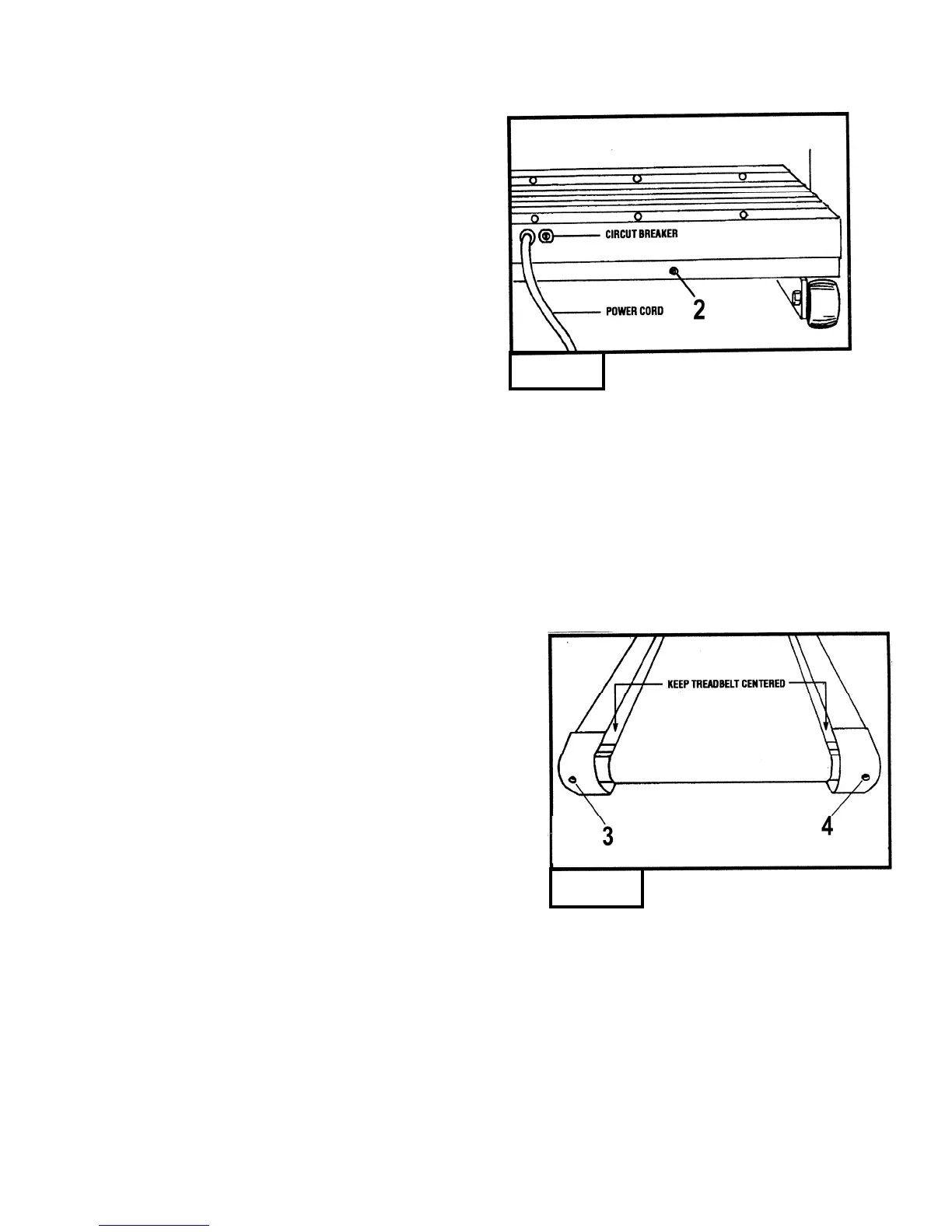

Locate the two tread belt adjustment screws (3) and (4) as shown.

Step Two:

Turn both the left and right tread belt adjustment screws 1/2 turn

clockwise.

Step Three:

Walk on the treadmill to see if the adjustment you made decreased

the slippage.

Step Four:

If a significant decrease in slippage was observed, go to step 2.

If you tighten the tread belt 1 1/2 turns per side and slippage is still

present, do not continue to adjust the tread belt tension. Contact

your authorized PaceMaster dealer.

Figure 8

Figure 9

Loading...

Loading...