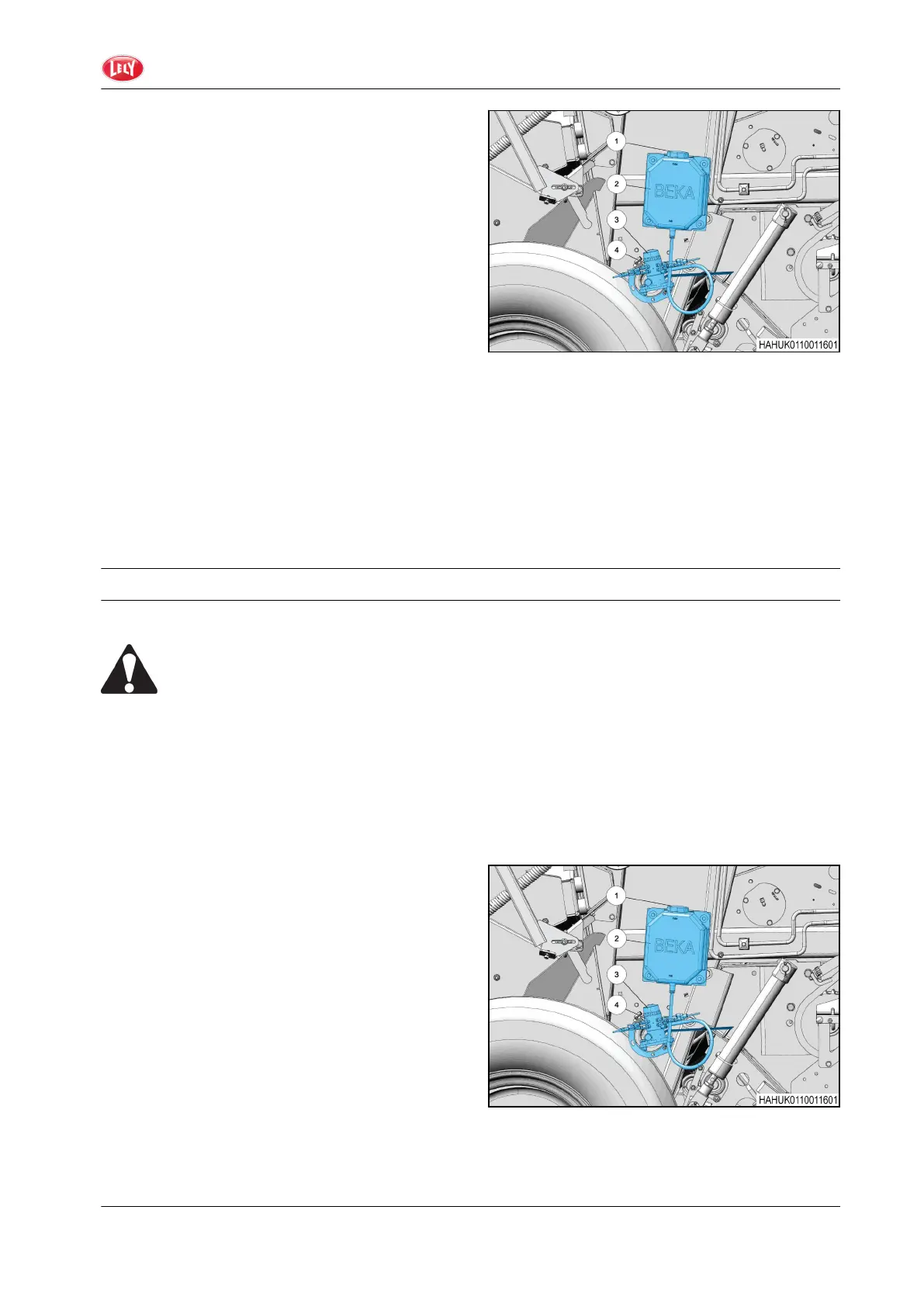

3. Remove the container cap (1).

4. Make sure that the filter is clean, if

necessary:

a) Remove the filter from the oil container

b) Clean the filter and use only petroleum-

benzine or petroleum

c) Put the filter in the oil container.

5. Put the new and clean oil through the filter

and fill the oil container until the oil is on the

maximum mark.

6. Make sure that you put the container cap on

the container.

GUID-DAE83B6E-EF23-4BEE-813A-4C8F5258B3B2-high.jpg [High]

Fig. 3

(1)

Cap.

(2) Oil container.

(3) Cap of the pump.

(4) Oil pump.

After finishing the procedure

Measure the oil quantity each two hours of operation after you fill the oil in the oil container.

If necessary adjust the oil quantity in the oil container again.

4.4.3 Bleed Air from the Lubrication Pump

Before starting the procedure

WARNING: Risk of injury.

Make sure that no person or animal go into the range of operation (danger zone (1 and 2))

while the Power Take-O (PTO) shaft is in operation.

IMPORTANT: Make sure that there is always lubricant in the pump to prevent an air bleed procedure. The

lubrication pump must have an air bleed when the oil container has oil fully removed and put in.

Procedure

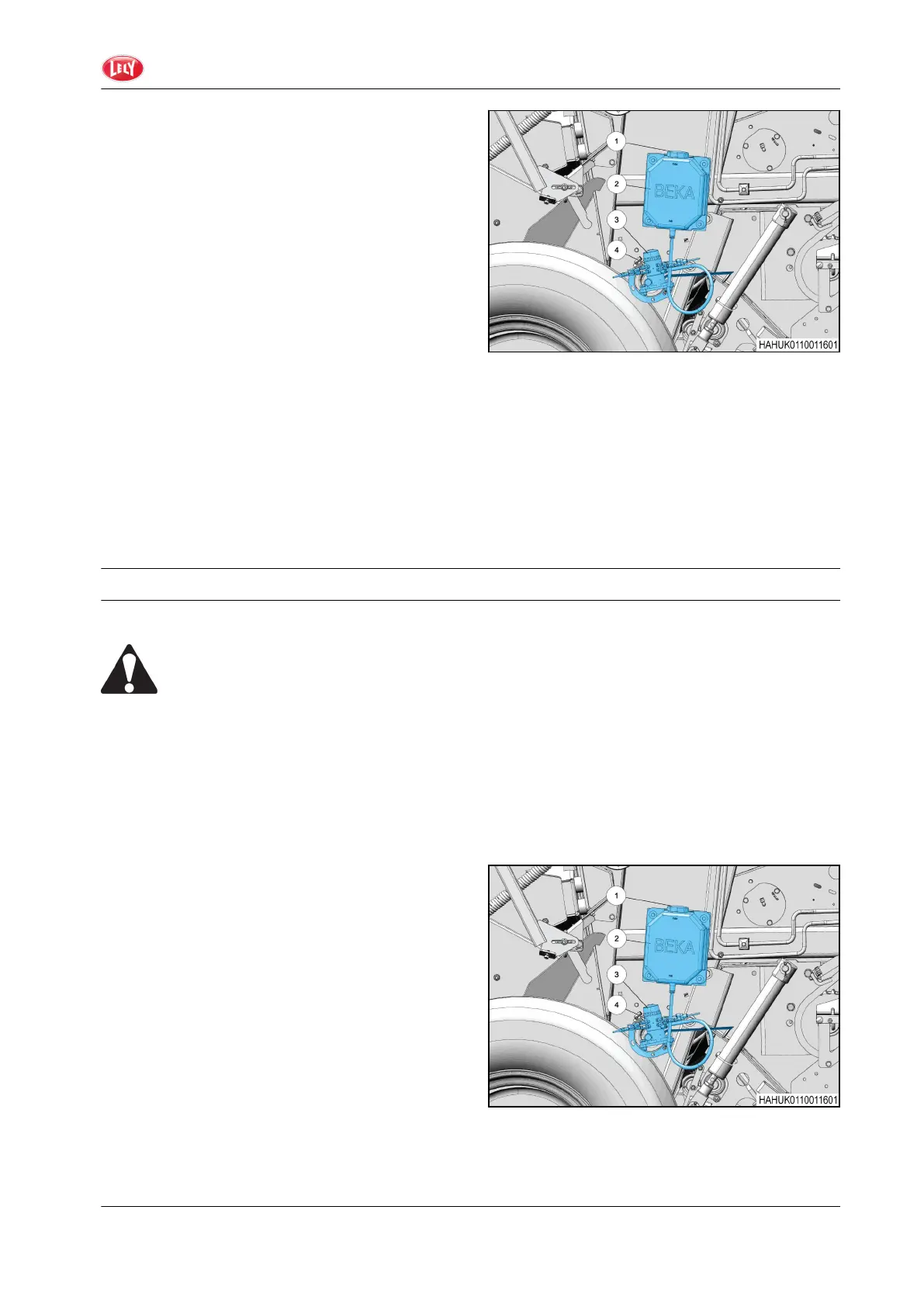

1. Disengage the PTO shaft, stop the tractor engine and remove the key.

2. Make sure that the parking brake of the tractor is on.

3. Disconnect all the tubes from the pump (4).

4. Put a container below the pump to collect

the drops of oil.

5. Start the tractor engine and engage the PTO

shaft, this starts the pump.

6. All the air bubbles will go from the pump

after 20 seconds.

7. Disengage the PTO shaft then stop the

tractor engine and remove the key.

8. Connect again all the tubes to the pump and

make sure that the connection is correct.

9. Measure the oil quantity and if necessary add oil to the oil container.

GUID-DAE83B6E-EF23-4BEE-813A-4C8F5258B3B2-high.jpg [High]

Fig. 4

Related Links

GUID-66686BE6-C595-4D8A-B77C-D5938E679273 [V1]

4. Maintenance and Lubrication

Baler Wrapper Combination 121

4900.LE.EN01

Loading...

Loading...