4.5 Roller Lubrication System Maintenance (RPC 130 F only)

Before starting the procedure

The roller lubrication system supplies lubricant from the lubricant container to the roller bearings. Examine

the level in the lubricant container daily.

CAUTION: Machine Damage

The roller lubrication system supplies lubricant from the container to the roller bearings.

Examine the level in the lubricant container daily.

CAUTION: Machine Damage

Damage to the lubrication pump, roller bearings and baler when the system operates with

the incorrect grease.

CAUTION: Environmental Hazard.

Do not leak grease.

Procedure

1. Make sure that the Power Take-O (PTO) shaft is "OFF", the tractor engine stopped and the key

removed.

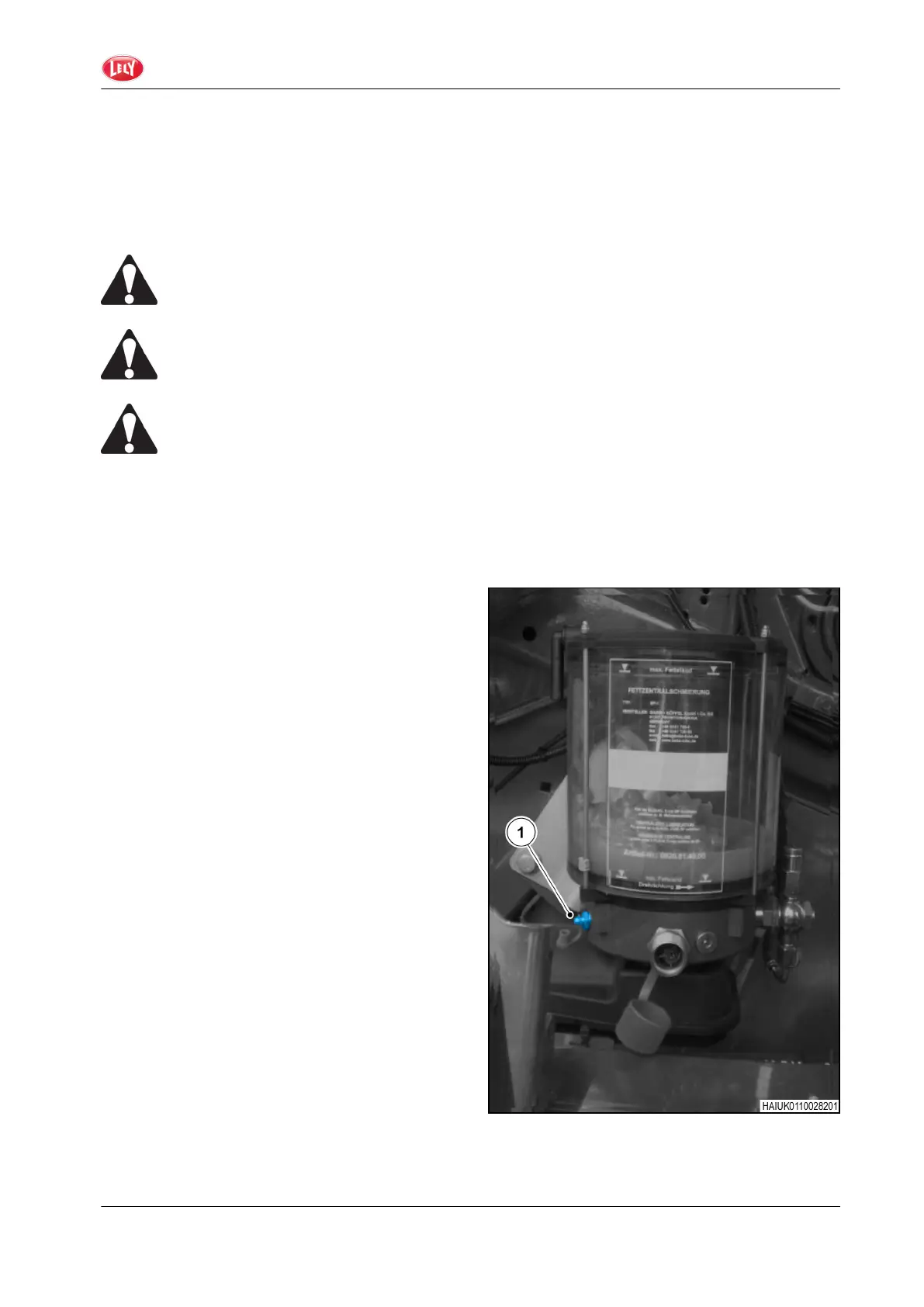

2. Examine the level in the lubricant container.

3. If necessary fill the lubricant container.

a) Make sure that the PTO shaft is "OFF",

the tractor engine stopped and the key

removed.

b) Clean the area around the lubricant

container, this helps prevents dirt in the

container when you open it.

c) Remove the container cap.

d) Fill lubricant container with the fill nipple

and a manual grease gun (1).

GUID-8A1B4607-DB01-43B2-83A7-3349F2CBCAB3-high.jpg [High]

Fig. 5

GUID-76719CF4-017B-4688-9E95-7D06C1270AA8 [V1]

4. Maintenance and Lubrication

Baler Wrapper Combination 123

4900.LE.EN01

Loading...

Loading...