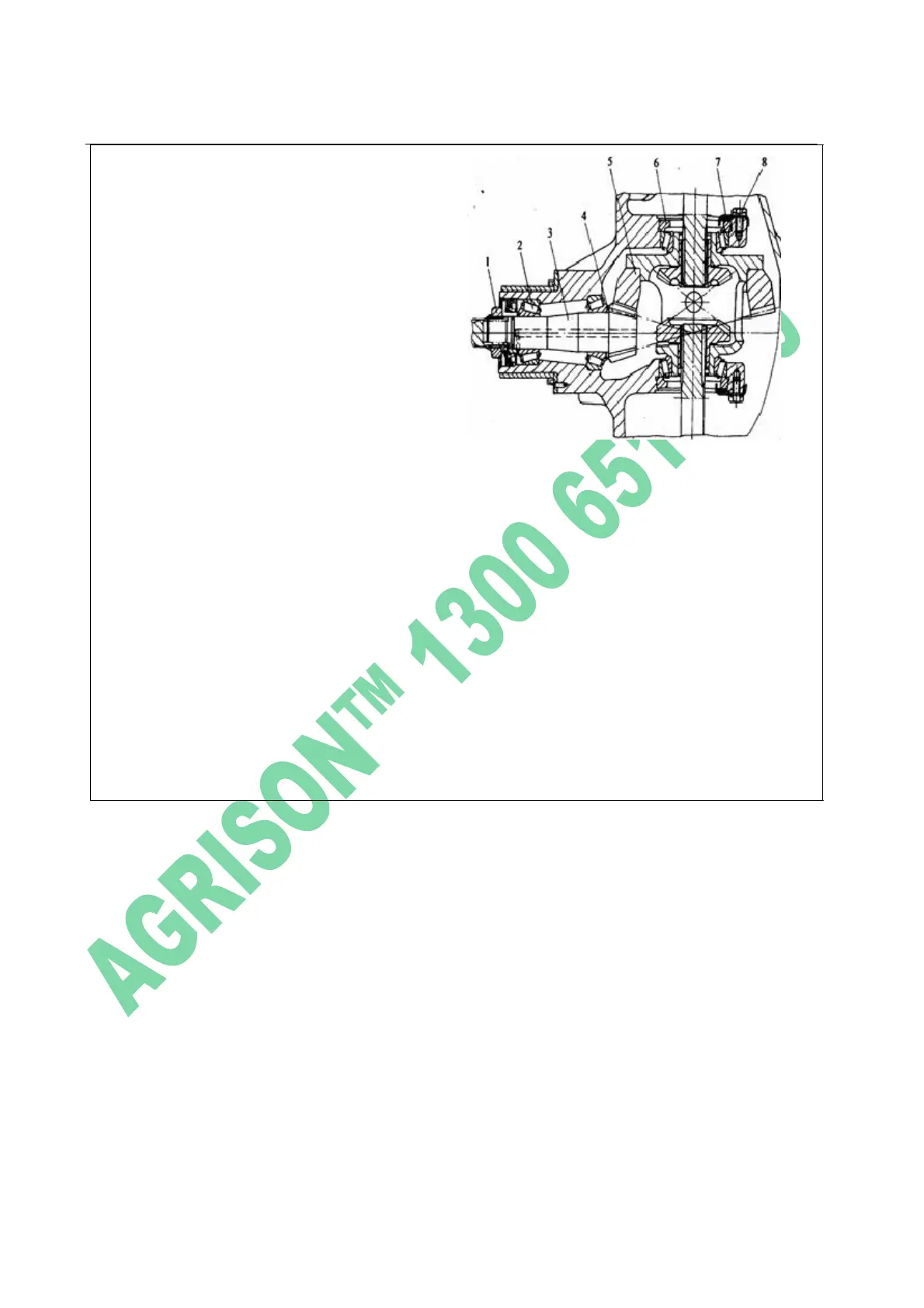

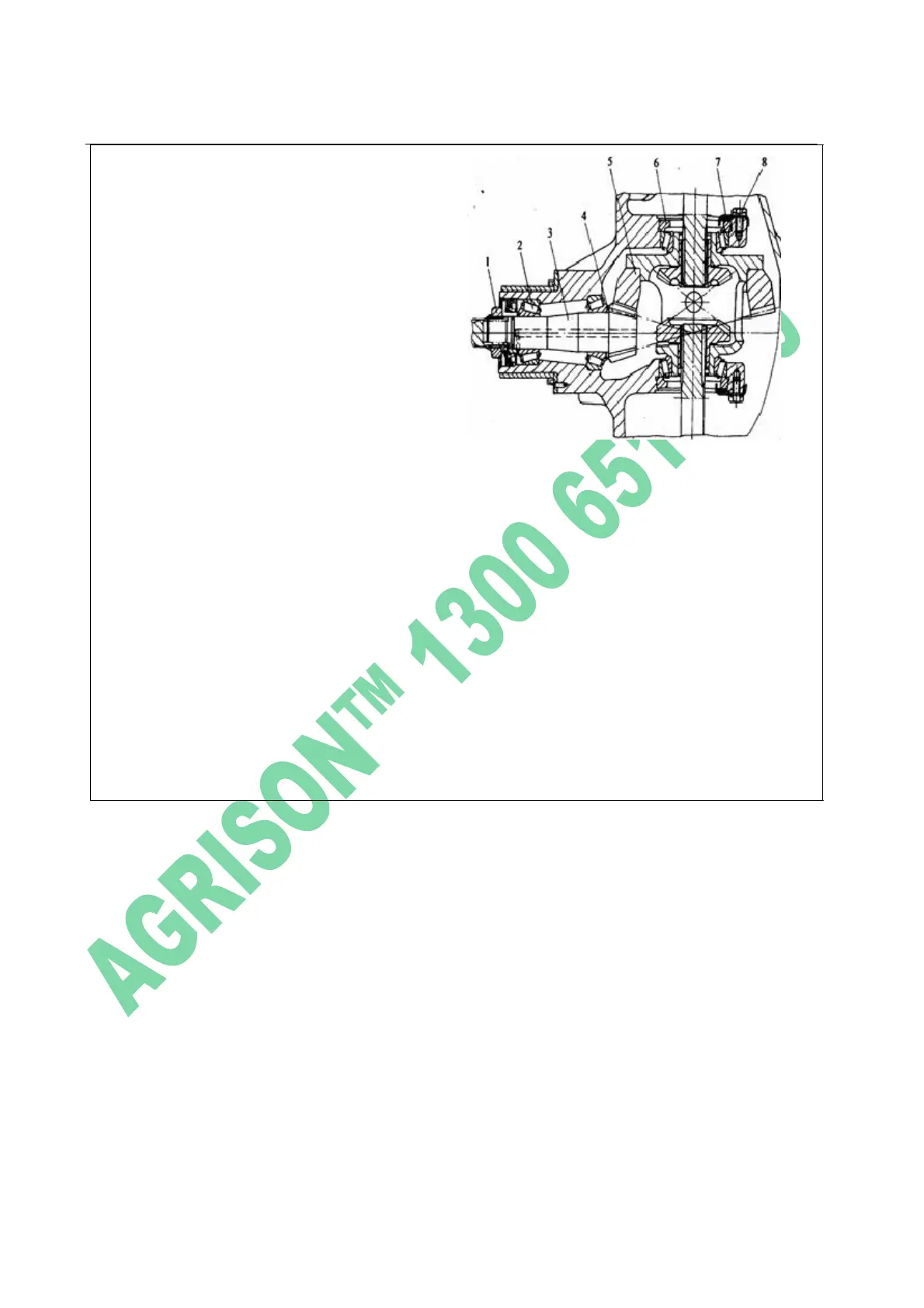

前驱动桥中央传动的调整见图。

Front drive axle center drive adjustment to the

Figure.

前驱动小锥齿轮轴上的 2 个圆锥滚子轴承及

存放

Storage

差速器壳上左、右 2 个圆锥轴承都是预紧的,

使用过程中,由于轴承的磨损,小锥齿轮轴

及差速器壳产生轴向游隙,因此应定期检查

(每 1600h 保养时)。小锥齿轮轴轴承的调整靠

调节螺母 l。调整时,先将螺母 1 拧紧,然后

退回 l/10~1/6 圈,最后将螺母锁紧。差

速器壳轴承的调整,应同时调整左、右调节

螺圈 6,使中央传动锥齿轮副的啮合间隙在

0.15mm~0.3mm 范围内,最后将调节螺圈 6

用锁片 7 锁紧。齿侧间隙和啮合印痕的检测

方法同后桥中央 传动的检测方法.

Front drive bevel pinion shaft two tapered roller

bearings and differential case on the right and

left two tapered bearings are preloaded using

the process, due to bearing wear, bevel pinion

shaft and differential shell produces axial

clearance should therefore be checked regularly

(every 1600h maintenance time). Bevel pinion

图 6-15 前驱动桥中央传动调整

Fig.6-15 Adjustment of central drive system of the front

drive axle

1.调节螺母;2.圆锥滚子轴承;3.小锥齿轮轴;

4.调整垫片;5.大锥齿轮;6.调节螺圈;

7.锁片;8.螺栓

1. Adjusting nut; 2. Tapered roller bearings;

3 bevel pinion shaft; 4 shims;5 large bevel gear;

6. Adjustment screw rings; 7. Locking tabs; 8. Bolts

shaft bearing adjustment by adjusting the nut l. Adjustment, first tighten the nut 1, then return l/10 ~ 1/6 laps,

finally nut. Differential case bearing adjustment should also adjust the left and right adjustment screw ring 6,

the central drive bevel gear meshing clearance in the range of 0.15mm ~ 0.3mm, the final adjustment screw

ring 6 7 Lock with locking tabs. Backlash and engaging prints detection methods with the rear axle center

drive detection method.

6.3.6.2 前驱动桥最终传动的调整

Final drive system adjustment of front axle

Loading...

Loading...