SmartCool

TM

- D

Precision Air Conditioning

22

Precision Air Conditioning

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Design Data – Water Cooled & Free Cooling

The dry cooler design duty is equivalent to the Total Heat of Rejection (THR) from the indoor unit.

This value can be taken from the performance data in the technical manual using the following.

Parameters required are:

• Ambient conditions (°C dB) Airedale recommend a 10°C lower than the EWT.

• Glycol content (%)

• Entering & leaving water/glycol temperatures (°C) (EWT and LWT)

• Mean condensing temperature (°C) Based on 5°C above leaving water/glycol temperature

Volumetric Flow Rate (l/s)

The maximum design volumetric flow rate can be calculated using the following equation:

x Cp x ∆T

Where:

Q = Total Heat Rejection (kW).

T = Temperature Difference between Water/Glycol Entering/ Leaving (°C).

= Density. Refer to table below.

Cp = Specific heat capacity. Refer to table below.

Pressure Drop (∆P

s

)

The maximum indoor unit pressure drop can be calculated using the following equation:

∆P

s

= ∆P

w

x P

Using the volumetric flow rate calculated above, the pressure drop (

Pw) can be taken from the

relevant pressure drop graph..

Where:

P

s

= Maximum Water/Glycol Pressure Drop for the indoor unit (kPa).

P

w

= Equivalent Water Pressure Drop for indoor unit (kPa).

P

= % Glycol Pressure Drop Correction Factor @ 20°C Water Temperature.

Refer to table below.

The resultant pressure drop (

P

s

) is the maximum pressure drop based on the indoor unit

running at the prescribed conditions.

This will typically occur when the water/glycol temperature is approximately 20°C and the

water/glycol is being circulated through the free cooling coil and through the water cooled

condenser.

The indoor unit pressure drop will reduce at other operating conditions.

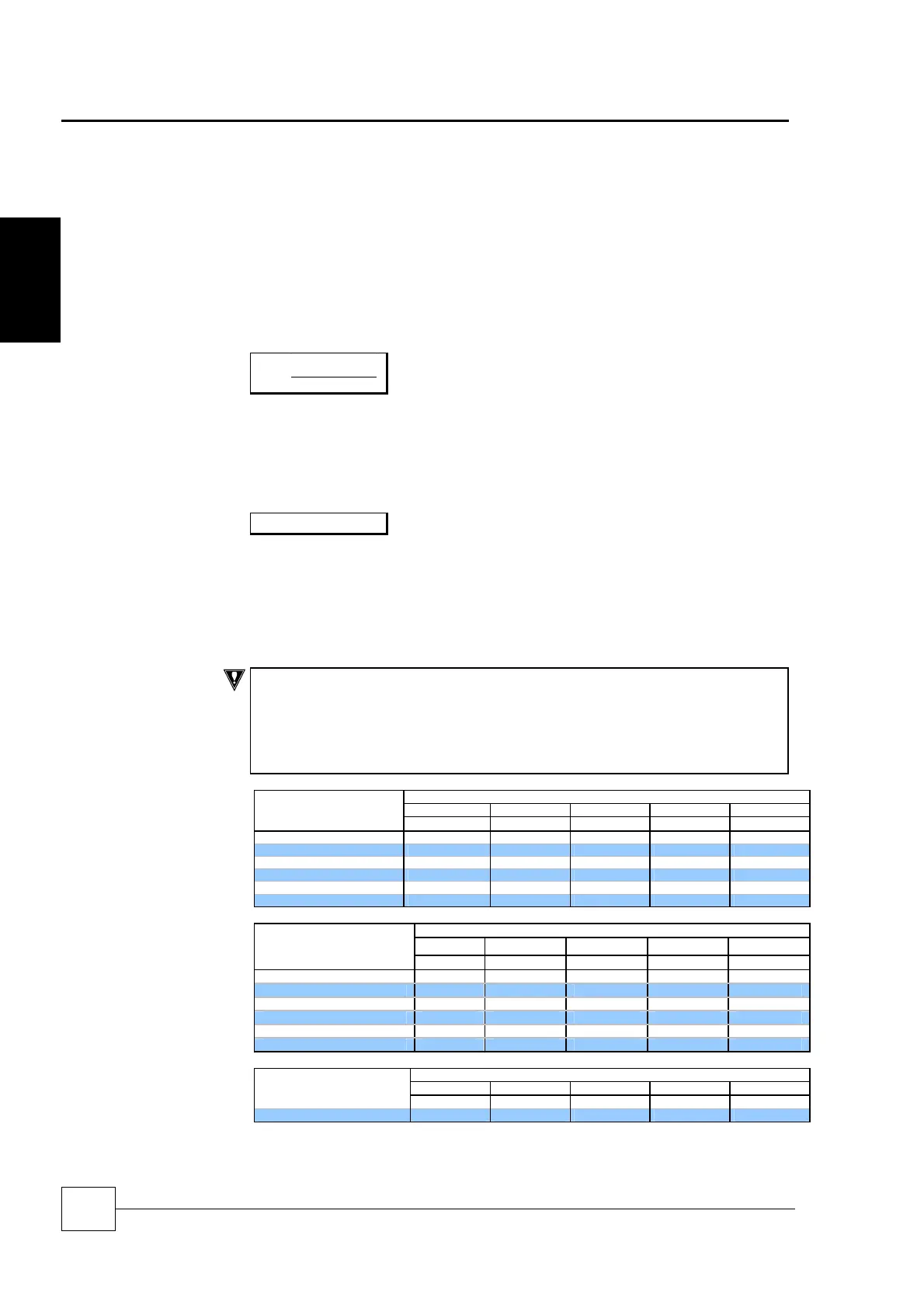

Specific Heat Capacity (Cp)

Water/Glycol Temperature °C

Ethylene Glycol (Volume) / Freezing Point °C

0% / 0°C 10% / -4°C 20% / -9°C 30% / -15°C 40% / -23°C

Fχ Fχ Fχ Fχ Fχ

20 4.183 3.972 3.815 3.645 3.468

25 4.181 3.981 3.826 3.660 3.485

30 4.179 3.989 3.838 3.674 3.502

35 4.178 3.998 3.849 3.688 3.518

40 4.179 4.007 3.861 3.702 3.535

45 4.181 4.015 3.872 3.716 3.552

Density (

)

Water/Glycol Temperature °C

Ethylene Glycol (Volume) / Freezing Point °C

0% / 0°C 10% / -4°C 20% / -9°C 30% / -15°C 40% / -23°C

Fχ Fχ Fχ Fχ Fχ

20 998 1013 1030 1045 1060

25 997 1012 1028 1043 1058

30 996 1010 1026 1041 1055

35 994 1008 1024 1039 1053

40 992 1006 1022 1036 1050

45 990 1003 1020 1035 1048

Factor (P

χ

)

Water/Glycol Temperature °C

Ethylene Glycol (Volume)

0% 10% 20% 30% 40%

Pχ Pχ Pχ Pχ Pχ

20 0.983 1.0125 1.054 1.0958 1.15

Installation

Loading...

Loading...