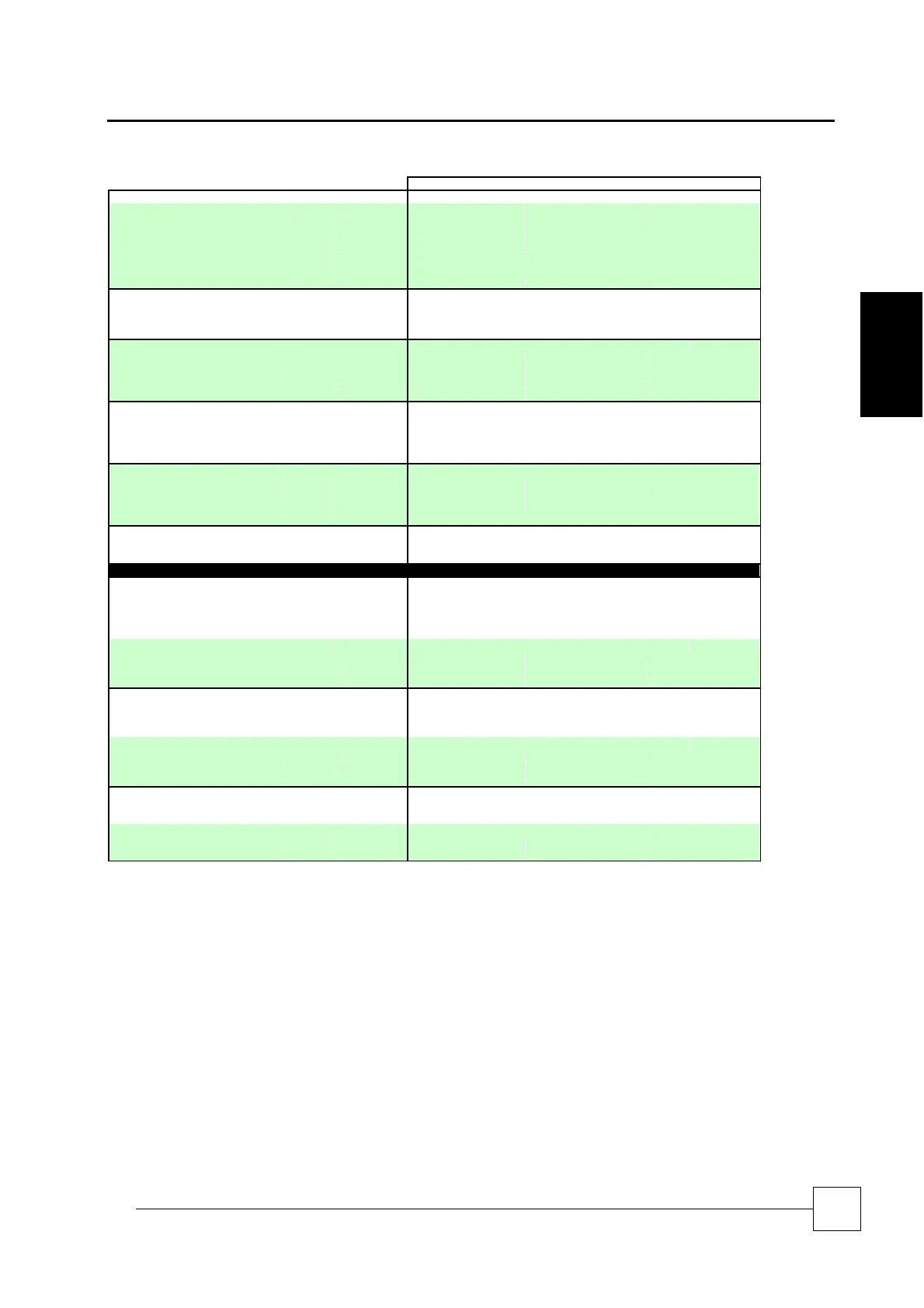

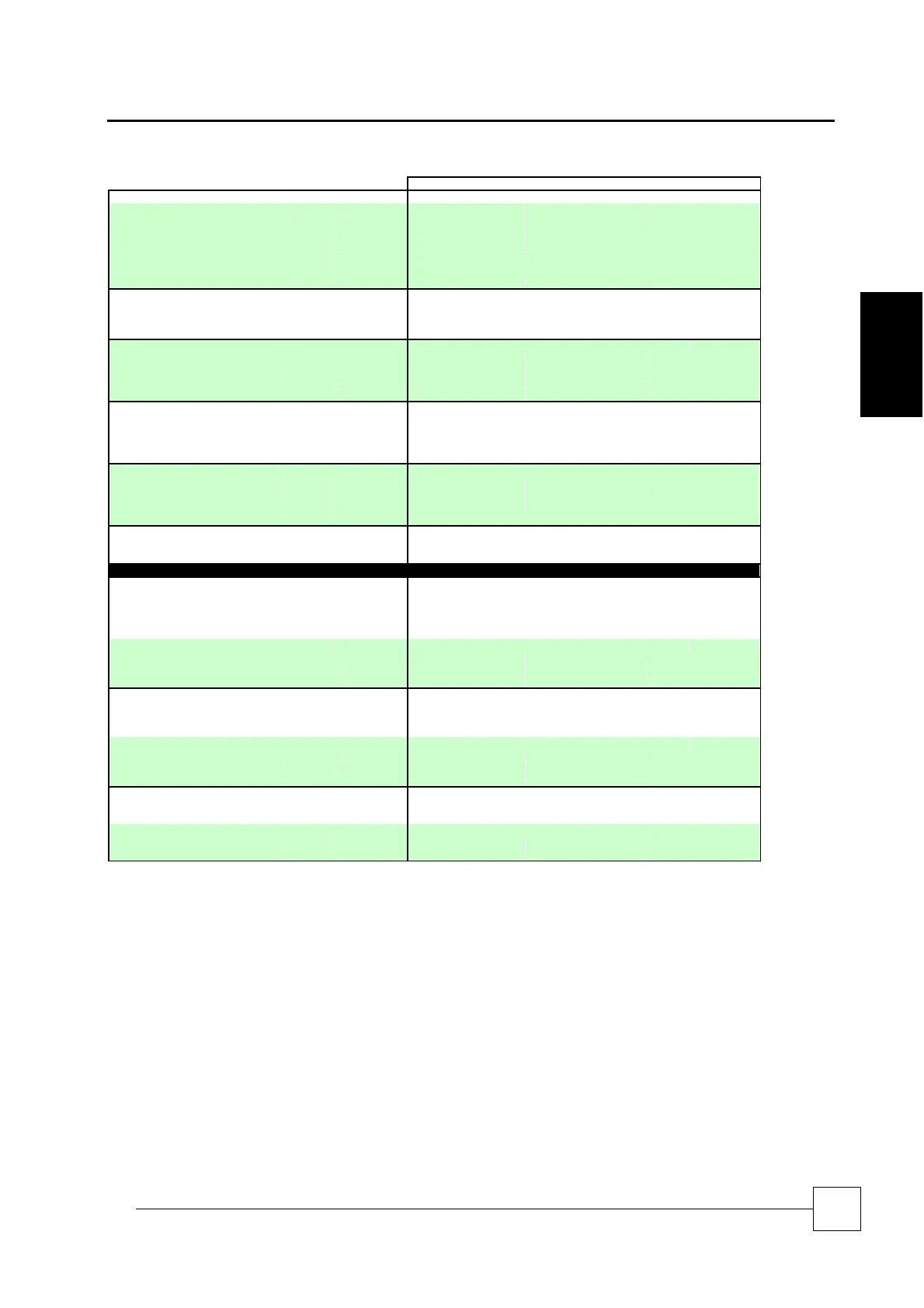

Electrical Data – X2X2 Continued

SC25D080-X2X2 SC25D090-X2X2 SC25D100-X2X2

Standard Condenser Match - 2 x CR65 2 x CR65 2 x CR80

Unit Data Full Function - X2X2

(1)

Nominal Run Amps A 90.5 89.9 100.7

Maximum Start Amps A 177.3 169.1 213.7

Recommended Mains Fuse Size A 125 125 125

Max Mains Incoming Cable Size mm² 70 70 70

Mains Supply V 400V / 3PH + N / 50Hz

Control circuit VAC 24 24 24

Unit Data Cooling Only – X2X2

Nominal Run Amps A 74.3 73.7 84.5

Maximum Start Amps A 161.1 152.9 197.5

Recommended Mains Fuse Size A 100 100 100

Evaporator Fan - Motor - Per Fan

Motor Type AC AC AC

Quantity x Motor Size (2) kW 3 x 2.38 3 x 2.38 3 x 2.38

Full Load Amps A 5 5 5

Locked Rotor Amps A 17.5 17.5 17.5

Compressor 1 , Circuit 1 & 2

(3)

Motor Size kW 6.31 7.19 7.19

Nominal Run Amps A 13.27 12.87 12.87

Locked Rotor Amps A 100 92 92

Type of Start Direct On Line

Compressor 2, Circuit 1 & 2

(3)

Motor Size kW 6.31 7.19 9.46

Nominal Run Amps A 13.27 12.87 16.93

Locked Rotor Amps A 100 92 130

Type of Start Direct On Line

Standard Condenser Match - AC Motor Per Fan

Quantity x Motor Size kW 2 x 0.6 2 x 0.6 3 x 0.6

Full Load Amps A 2.62 2.62 2.62

Electric Heating

Stage of Reheat 2 2 3

Number of Elements 6 6 9

Rating (Total) kW 21 21 31.5

Current Per Phase A 30.31 30.31 45.47

Humidifier

Capacity kg/hr 15 15 15

Rating kW 11.25 11.25 11.25

Full Load Amps A 16.2 16.2 16.2

Standard Size Fan Motor - EC Motor –Per Fan

Quantity x Motor Size kW 2 x 2.2 2 x 2.2 2 x 2.2

Full Load Amps A 3.3 3.3 3.3

Locked Rotor Amps A 3.3 3.3 3.3

Larger Size Motor - EC Motor - Per Fan

Quantity x Motor Size kW 2 x 3.1 2 x 3.1 3 x 3.1

Full Load Amps A 4.8 4.8 4.8

Locked Rotor Amps A 4.8 4.8 4.8

Standard Condenser Match - EC Motor-Per Fan

Quantity x Motor Size kW 2 x 0.73 2 x 0.73 3 x 0.73

Full Load Amps A 3.3 3.3 3.3

SCAF Condenser Match - Motor-Per Fan

Quantity x Motor Size kW 2 x 1.4 2 x 1.4 3 x 1.4

Full Load Amps A 6 6 6

(1) Values given for function units with standard selections for heating, humidification, supply air fans and matched condenser

at 7°C evaporating and 54.4°C condensing

(2) Stated motor power is based on maximum electrical power absorbed

(3) Values are per compressor

X2X2

Loading...

Loading...