Page 6

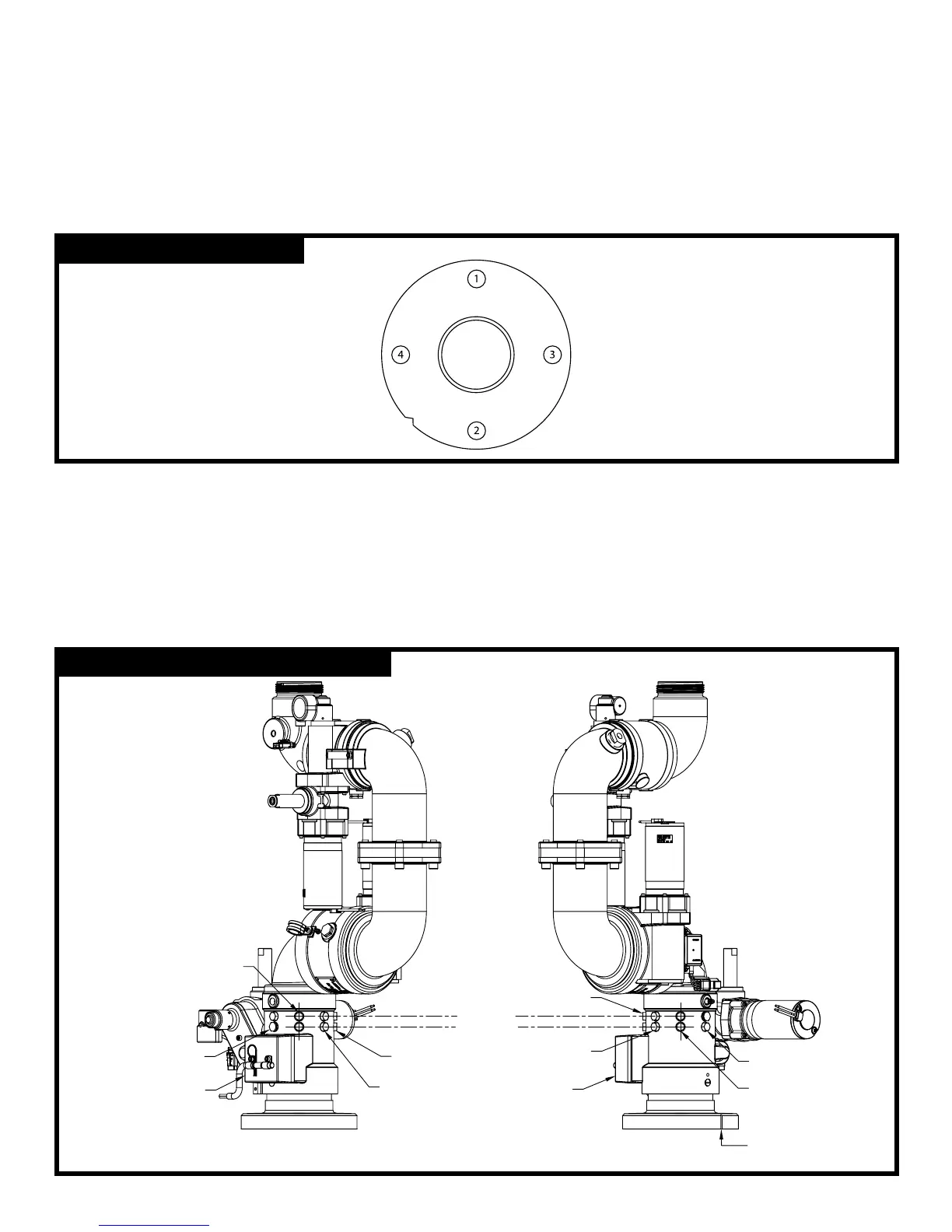

Bolt Spec and Tightening Procedure

Use four 5/8” bolts and nuts of grade ve minimum and suitable washers. There must be a minimum of six threads of

engagement. Use a ring gasket conforming to ASME 16.21. The notch that is cut into the side of the inlet ange is the

front of the monitor (see Figure 2).

Start the bolt tightening procedure by lubricating the nuts and bolts. Hand tighten the nuts until they are snug against

the ange. The nal torque of the bolts should be a maximum of 100 lb-ft. Following the correct sequential order as

shown in gure 2, tighten the bolts to 30% of the nal torque. Repeat the tightening sequence to 60% of the nal

torque. Repeat a third time to 100% of the nal torque. Finally, repeat the sequence at the nal torque.

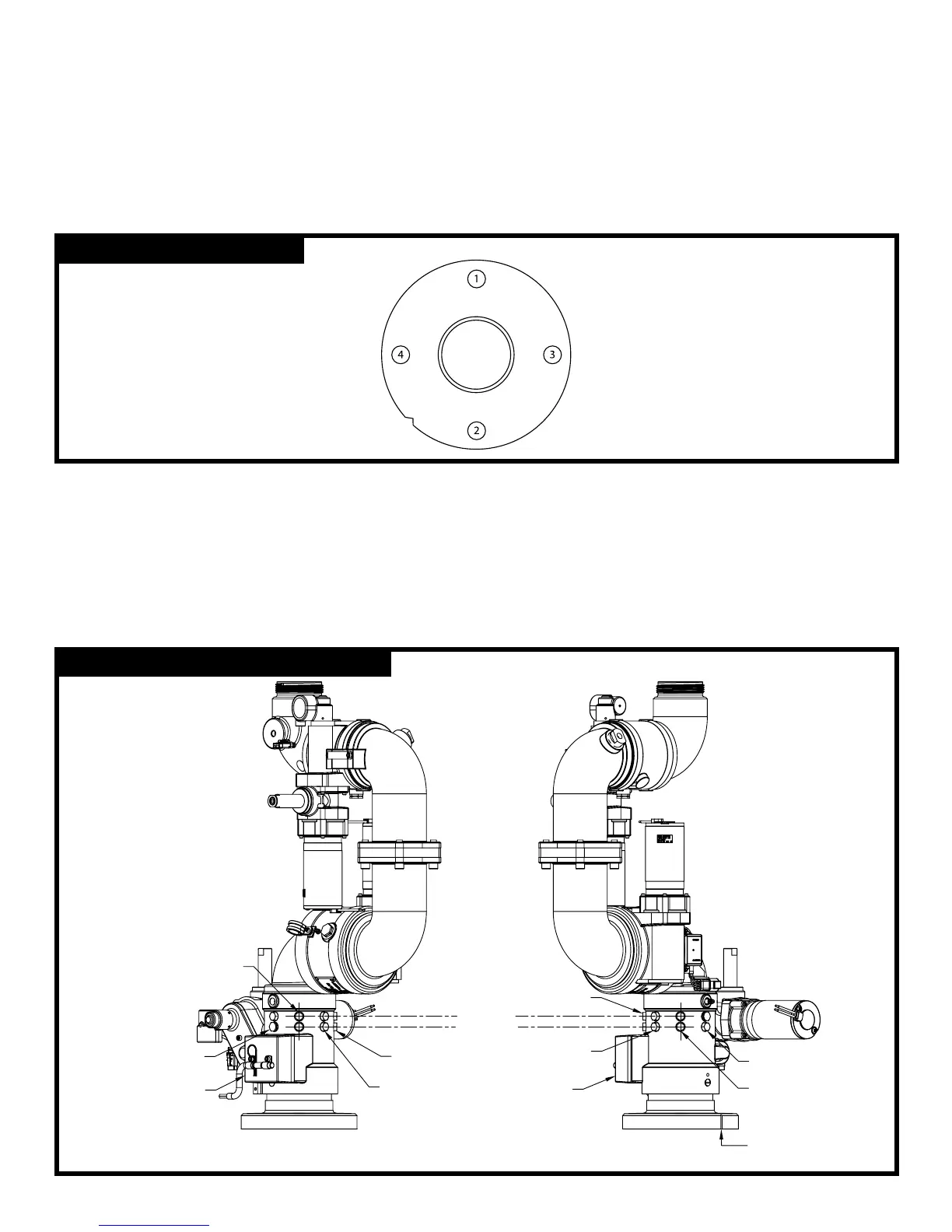

Rotational Hard Stops

The stainless steel rotational hard stops set the boundaries for the area that the monitor is allowed to travel left

(counterclockwise) and right (clockwise). The stop in the lower row controls the left (CWW) travel, and the stop in the upper

row controls the right (CW) travel. Refer to gure 3 for the locations of the upper row and the lower row, as well as points 1-5.

The monitor is shipped with a stop in the lower row at point 1, which stops the monitor at -170° CCW, and a stop in the

upper row at point 5, which stops the monitor at +170° CW. To set a different boundary area, swap the positions of the

steel hard stop and a plastic plug. Refer to gure 4 to select a desired boundary area. Both the stops and the plugs

have a 1/2” hex head.

FIGURE: 2 - Bolt Torque Order

FIGURE: 3 - Hard Stop and Plug Locations

HARNESS

JUNCTION BOX

#2

#3

NOTCH AT

FRONT OF

MONITOR

#4

#5

UPPER ROW

LOWER ROW

HARNESS

#1

#2

#3

#4

Loading...

Loading...