3

CD25C/28C/35C LPG Supplement

37.0

14.8

3 BOILER LOCATION

Installation pipes, cylinders and pressure regulators should be fitted in accordance with BS 5482:1. Bulk tank installation must

comply with the requirements of the Home Office code of practice for the storage of liquefied petroleum gas at fixed installations.

The boiler must not be installed in a room or internal space below ground level, e.g. in a basement or cellar, except where at

least one side is open to ground level.

4 INSTALLATION

In addition to the regulations and requirements stated in the Installation and Servicing instructions, the boiler must be installed

in accordance with BS 5482:1 - The Installation of Propane Burning Appliances in Permanent Dwellings.

2.3 GAS SUPPLY

The Alpha CD25C boiler requires a gas rate of 1.87 kg/h (4.0 lb/h) or 3.6 litres/h of liquid gas.

The Alpha CD28C boiler requires a gas rate of 2.22 kg/h (4.8 lb/h) or 4.2 litres/h of liquid gas.

The Alpha CD35C boiler requires a gas rate of 2.67 kg/h (5.7 lb/h) or 5.0 litres/h of liquid gas.

The supply pipes must be capable of delivering this quantity of gas in addition to the demand from any other appliances in the

house. The boilers require at least a 22 mm gas supply pipe.

The complete installation must be tested for gas soundness against leakage.

The local Propane gas supplier should be consulted, at the installation planning stage, in order to establish the availability of an

adequate supply of gas.

37.0

14.8

14.2

3.13

15.6

3.44

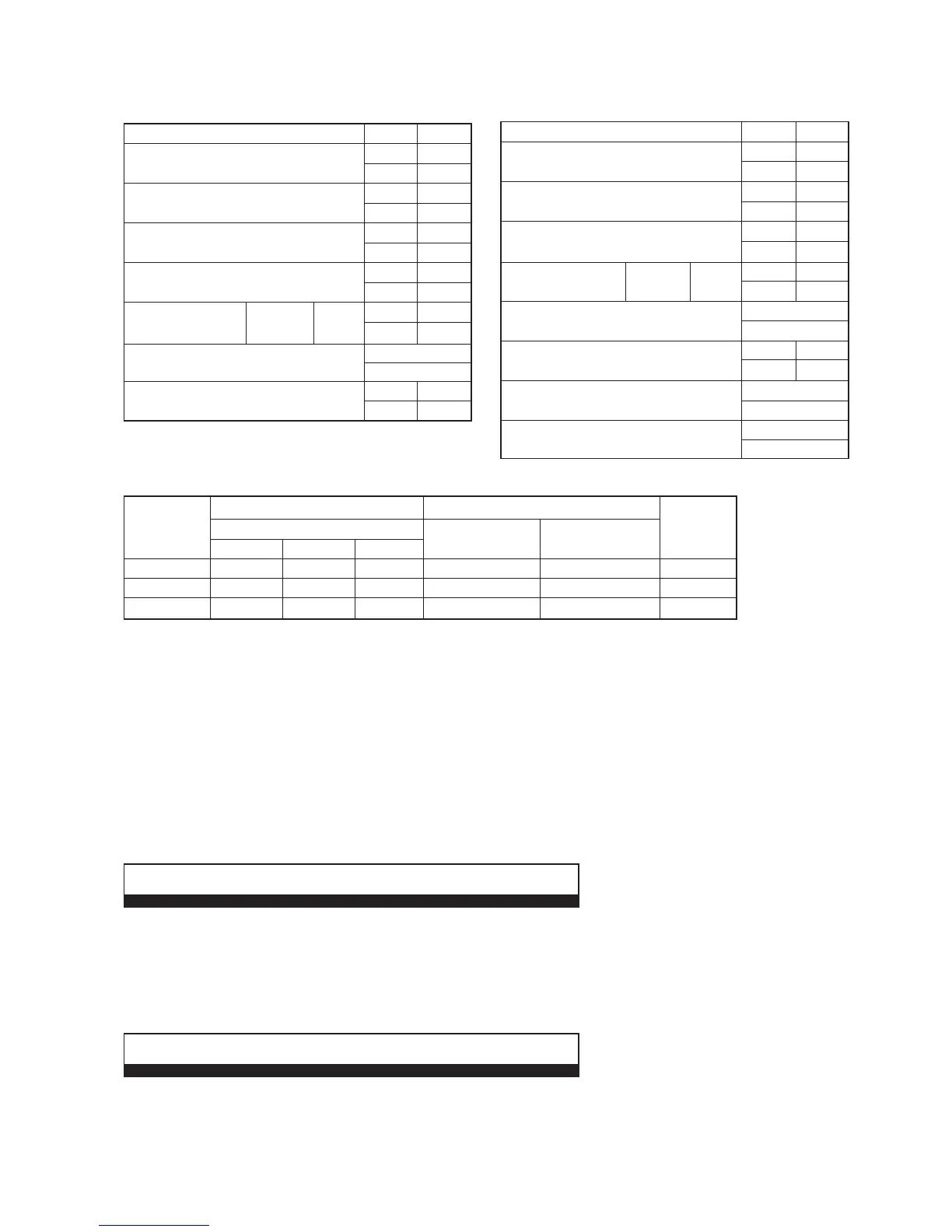

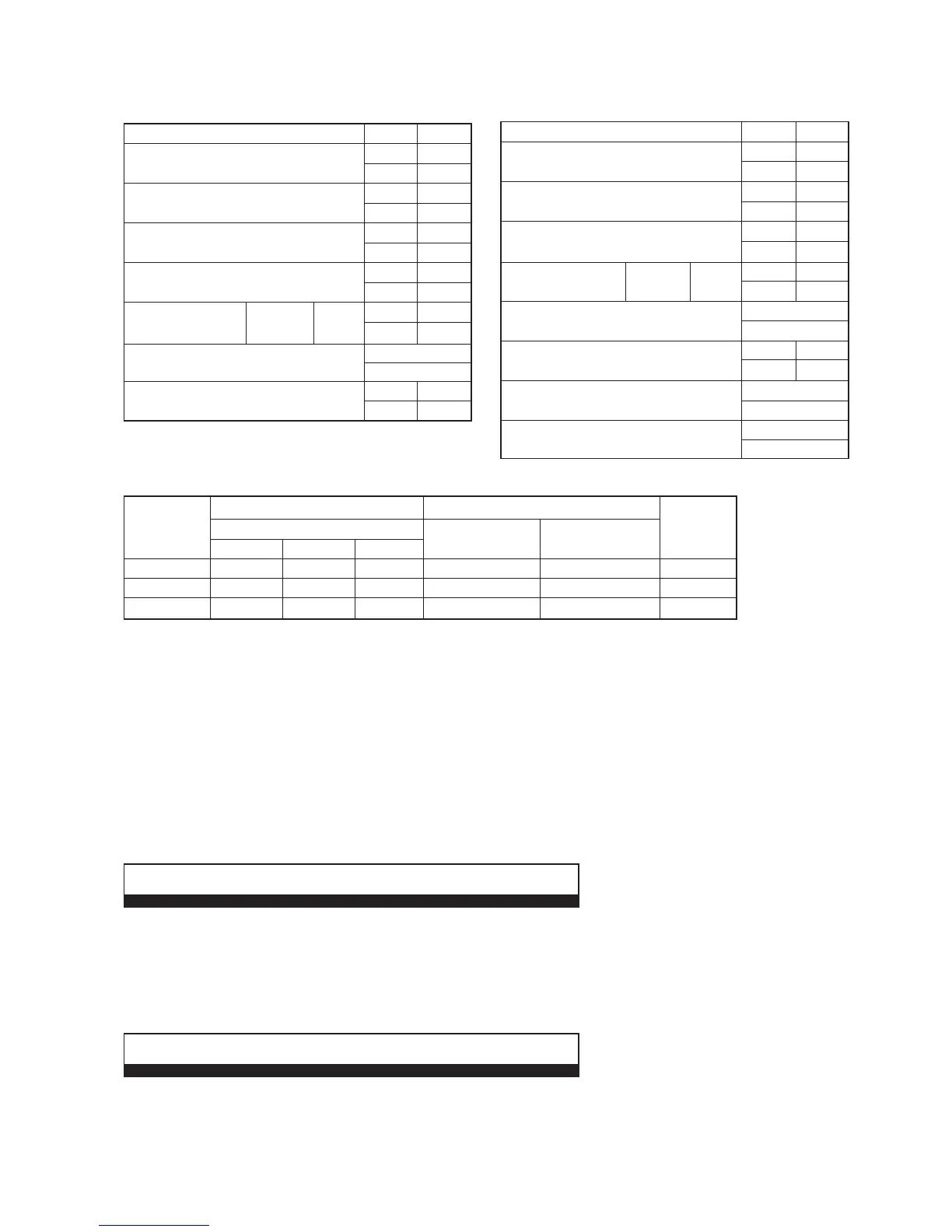

Alpha CD35C

MAX.

38.0

129 600

34.3

117 000

34.6

118 100

3.43

1.37

1.46

51.5

MIN.

8.9

30 600

8.1

27 600

8.0

27 300

0.23

0.09

0.34

12.0

Domestic Hot Water

Heat Input (H

s

)kW

(Gross) Btu/h

Heat Input (H

i

)kW

(Net) Btu/h

Output to Water (H

s

)kW

(modulating) Btu/h

Differential Burner mbar

Pressure in wg

Gas Supply Pressure (LPG) mbar

in wg

Gas Rate (LPG) m³/h

ft³/h

Flow Rate at 35°C Rise L/min

gal/min

Specific Flow Rate (D) at 30°C Rise L/min

(Flow rate @ 30K to EN625) gal/min

Room sealed

chamber

panel fitted

Alpha CD35C

MAX.

31.6

107 800

28.5

97 200

30.3

103 400

28.0

95 550

2.49

1.0

1.21

42.7

MIN.

8.9

30 600

8.1

27 600

8.5

29 000

7.8

26 600

0.23

0.09

0.34

12.0

Room sealed

chamber panel

fitted

Central Heating

Heat Input (H

s

)kW

(Gross) Btu/h

Heat Input (H

i

)kW

(Net) Btu/h

Heat Output (H

s

condensing) kW

(50°C/30°C) Btu/h

Heat Output (H

i

non-condensing) kW

(80°C/60°C) Btu/h

Differential Burner mbar

Pressure in wg

Gas Supply Pressure (LPG) mbar

in wg

Gas Rate (LPG) m³/h

ft³/h

%CO

2

content (± 0.2%) Sedbuk rating

LPG (propane) Efficiency

band

A

A

A

SAP efficiency

(%)

91.9

91.6

92.4

Min

10.0

10.1

9.1

CH Max

10.7

10.6

10.7

DHW max

10.6

10.6

10.8

NOx class

5

5

5

Boiler model

CD25C

CD28C

CD35C

Loading...

Loading...