6/20 Chapter 1 GENERAL DESCRIPTION

Issue 05/2010 OPERATOR’S MANUAL HFE M2 – X41176B

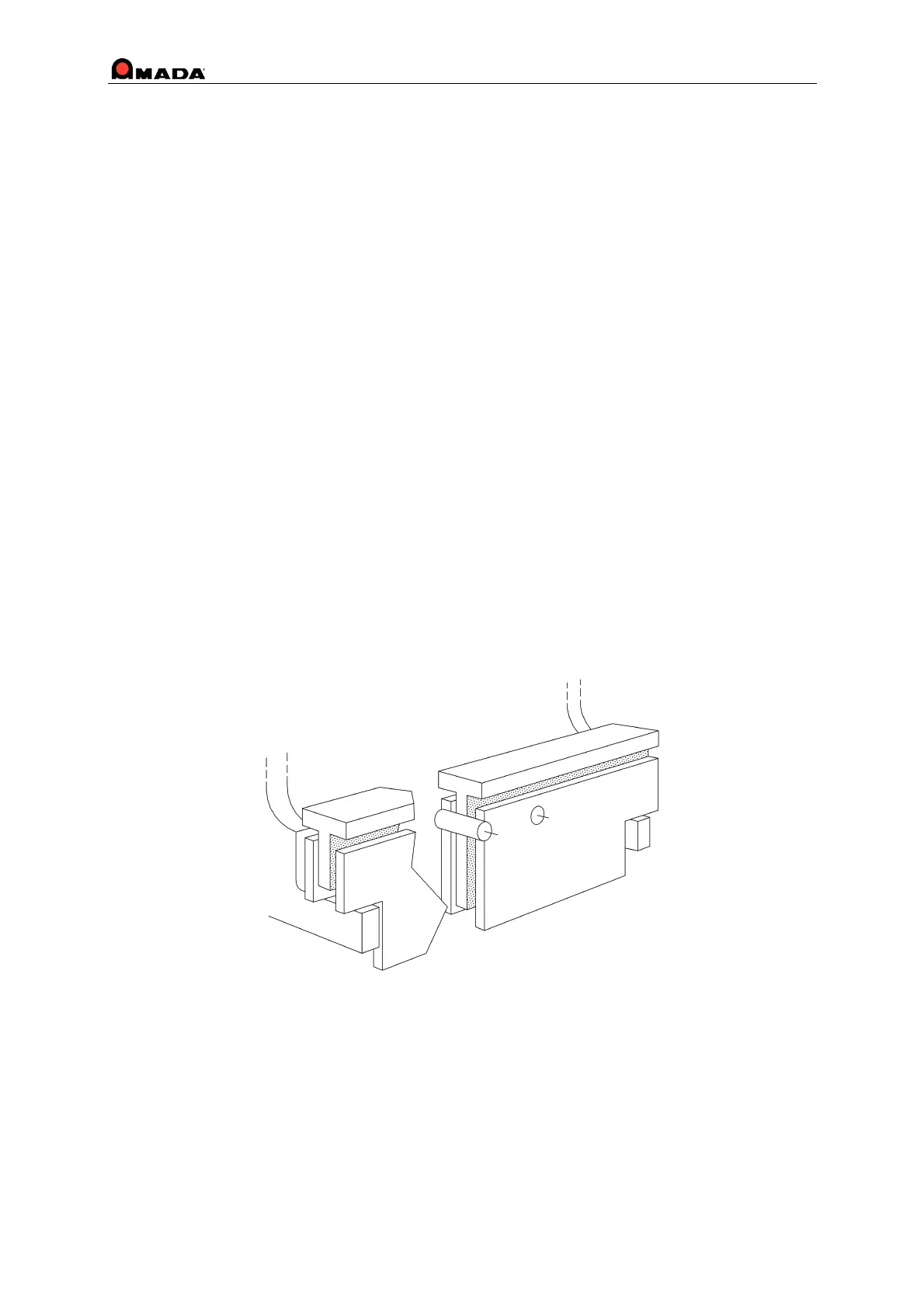

AMADA SYSTEM: Slotted beam (for 50 to 100 -ton press brakes).

The lower beam is a slotted plate. The arrangement, size, and shape of the slots are designed

to allow the lower beam to deflect in the same direction and with the same deflection as the

upper beam under the action of the bending force. The lower beam is welded to the flanges

(Fig. 1.3).

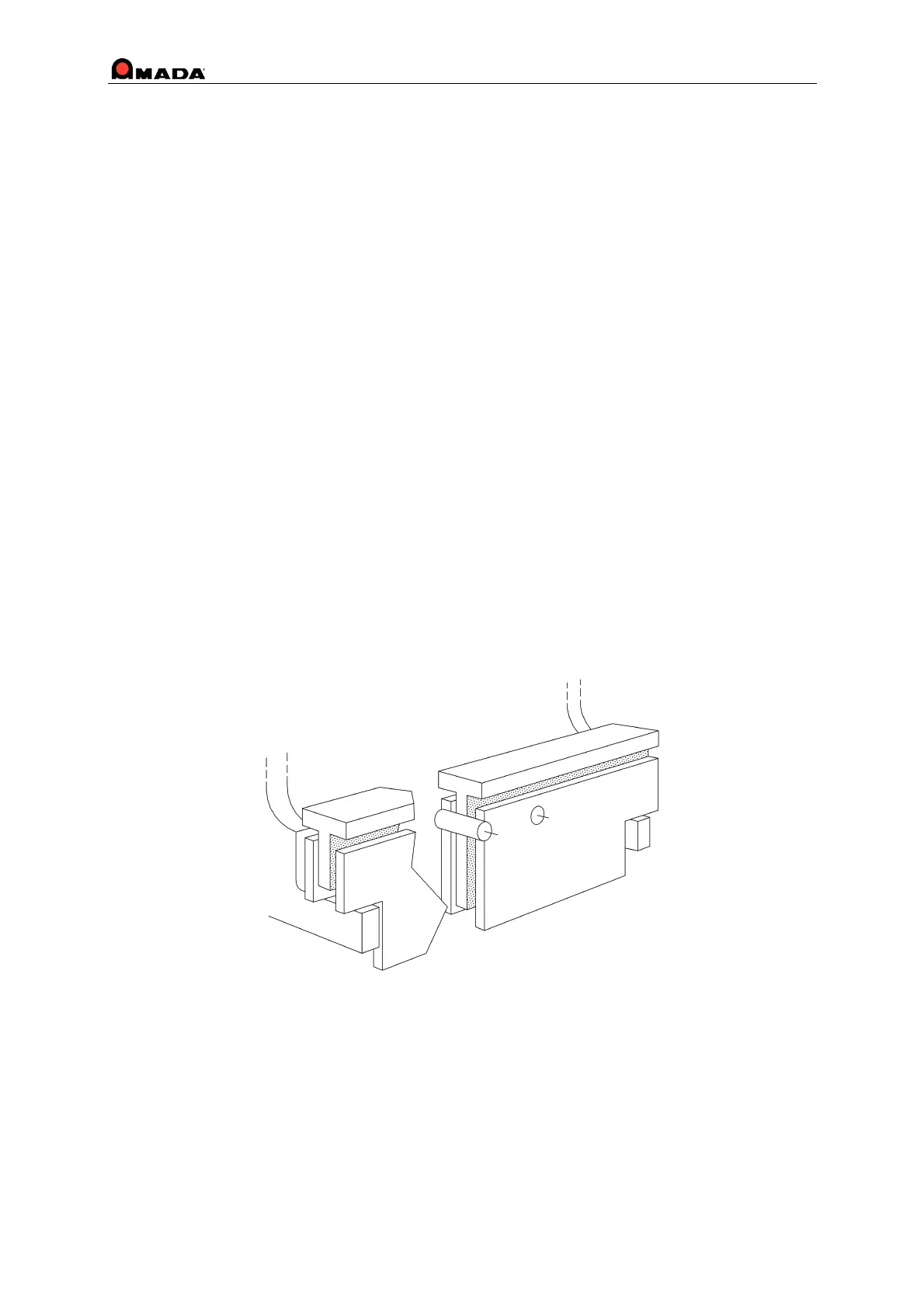

From 130 to 400 tons.

The lower beam (A) is assembled between two lateral cheeks (B and B') welded to the flanges

through two largely dimensioned pins positioned on both ends of the machine’s central axis

(Fig. 1.3) or (Fig. 1.3’). When bending, reaction forces tend to deform the lower beam in the

same direction and parallel to the upper beam. (Fig. 1.4).

ADVANTAGES

Due to the minor but inevitable elastic deflection of both beams in the same direction and

with the same value, the punch has constant penetration in the die over the entire bending

length, thus ensuring a perfect angle.

The minor deflection of the beams does not affect the linearity of the bend because the stress

induced in the beam remains well within the elastic region.

Up to 220 tons

Fig. 1.3

A

B

B’

Loading...

Loading...