Putting to operation

15

AMATRON II-A DB 599 09.01

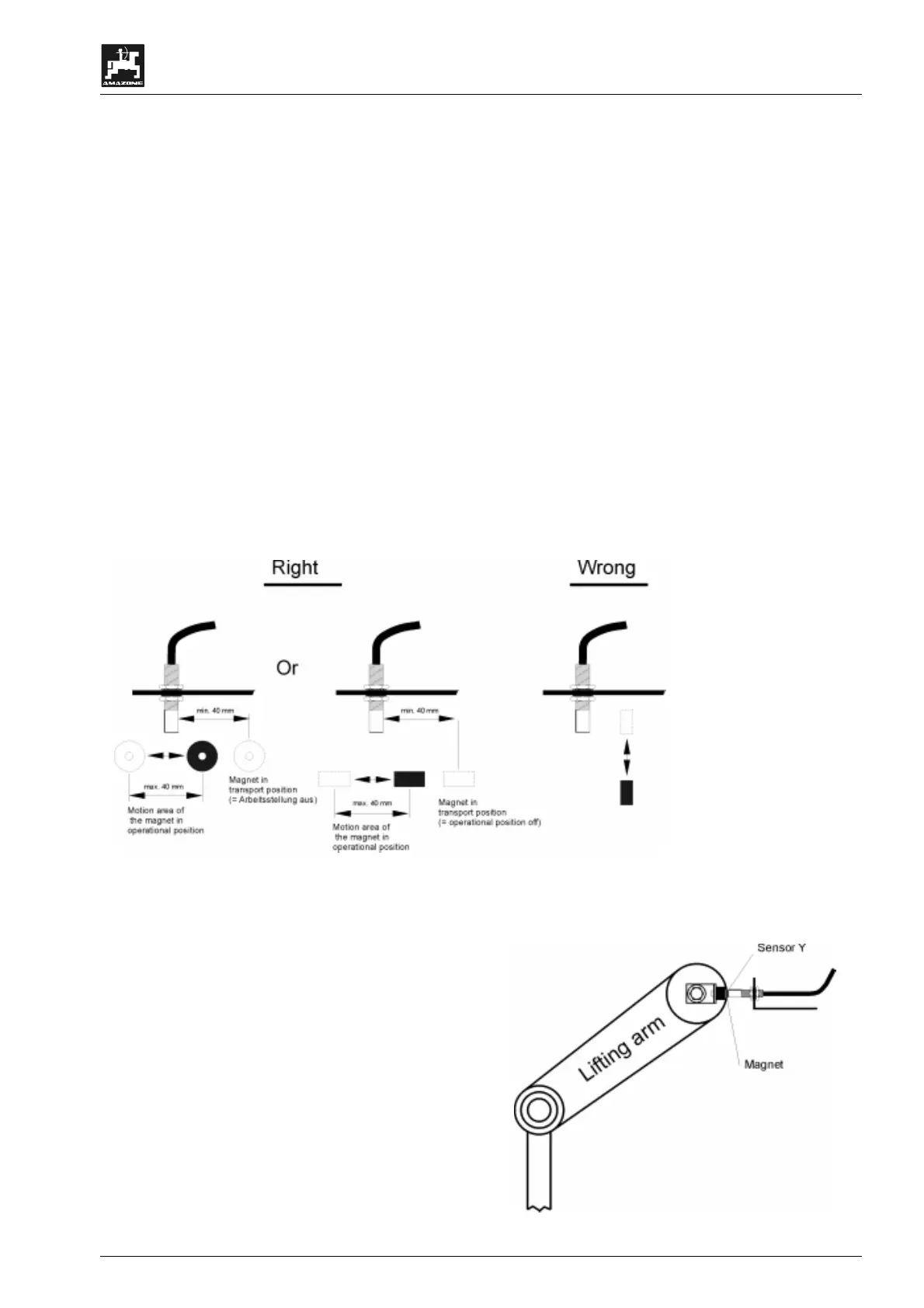

4.2.4 Sensor Y (operational position)

Connect sensor Y (18) via the 3-pole bushing with the

tractor signal distributor (16). Herewith information

about the operational position is given, e.g. on soil

tillage implements by the three point hydraulics or on

the beet puller from the breaker coulter. If a switch box

or an implement adapter (e.g. field sprayer) is avail-

able, the computer receives information about the

operational position from the implement plug (4). In

this case the sensor is without any function.

Example: Tractor three point hydraulics.

Fig. 4

F

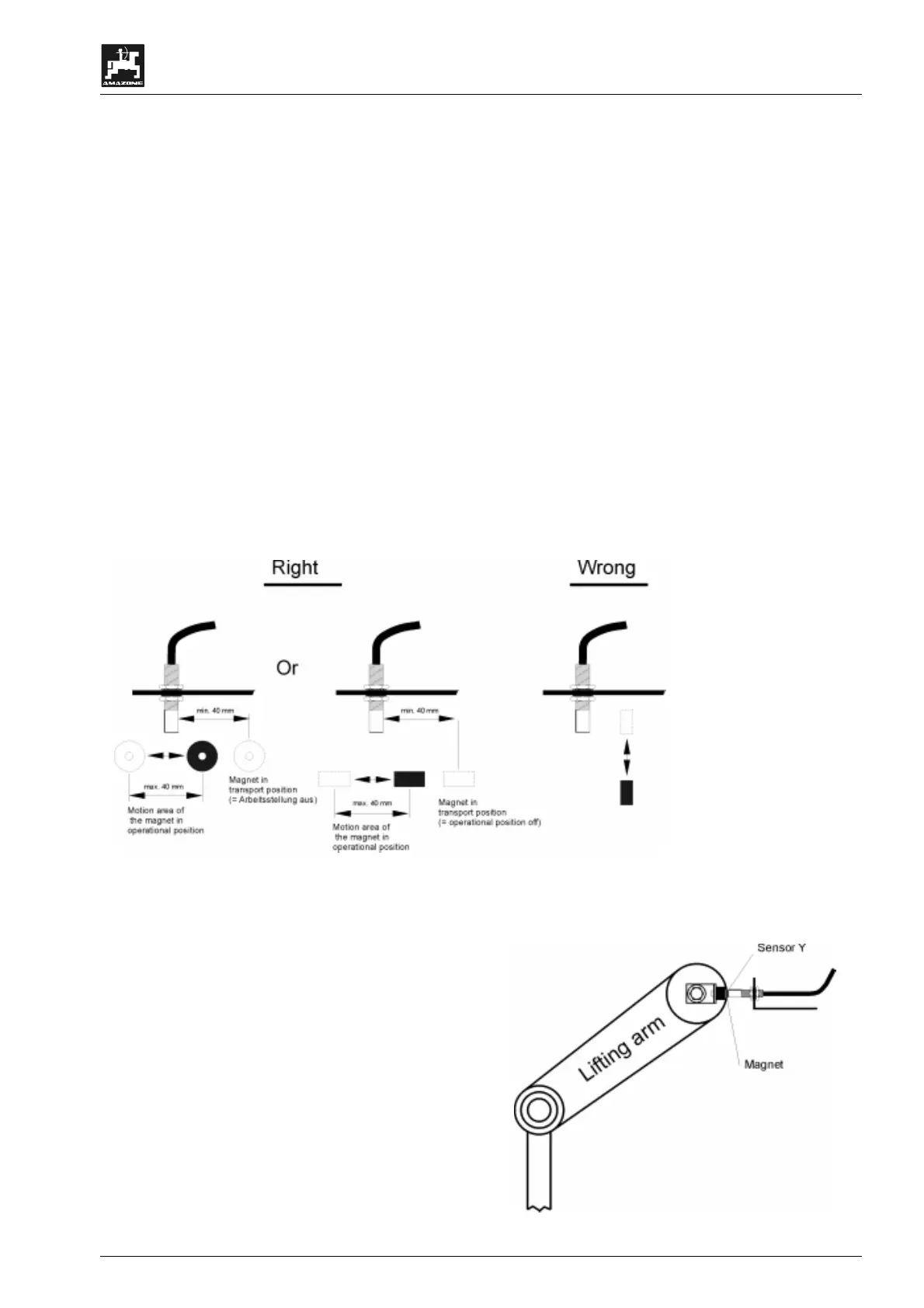

By using the provided V4A-steel bolt

the magnet is fitted to an implement

part which does not change from

transport into operational position.

The sensor is installed on an oppo-

site, fixed part of the vehicle. When in

operational position the magnet must

be in front of the sensor. The LED

"operational position" lights up on the

computer.

F

If the machine part to be monitored is

moving from the operational position by

more than 4cm from the solenoid

switch, a second magnet should be

fitted in the direction of movement of

the magnet. If the machine is in trans-

port position the magnet should have a

minimum spacing of 40 mm from the

solenoid switch..

Fig. 3

Loading...

Loading...