Maintenance, repair and care work

Cirrus 3/4/6000 DB2034 08.04

147

10.4.2 Inspection advice for the dual circuit air brake system (workshop job)

10.4.2.1 Leak test – quarterly (workshop job)

• Check all connections, tube-, hose and bolted joints for leakage.

• Remedy any leakage.

• Remedy rubbing points on tubes and hoses

• Replace porous and damaged hoses

• The dual circuit service brake system is considered to be tight when the engine is

stopped and the drop in pressure does not exceed 0.10 bar within 10 minutes, so

not more than 0.6 bar per hour.

• In case any values are not maintained, have the brake system checked in a

professional workshop.

• Tighten leaking points or replace leaking valves.

10.4.2.2 Checking the pressure in the air pressure reservoir – quarterly (workshop job)

Connect the pressure gauge on the checking point of the air pressure reservoir.

Rated value: 6,0 to 8,1 +0,2 bar.

If the rated value is not maintained, have the brake system checked in a professional

workshop

10.4.2.3 Cleaning the hose filters- quarterly (workshop job)

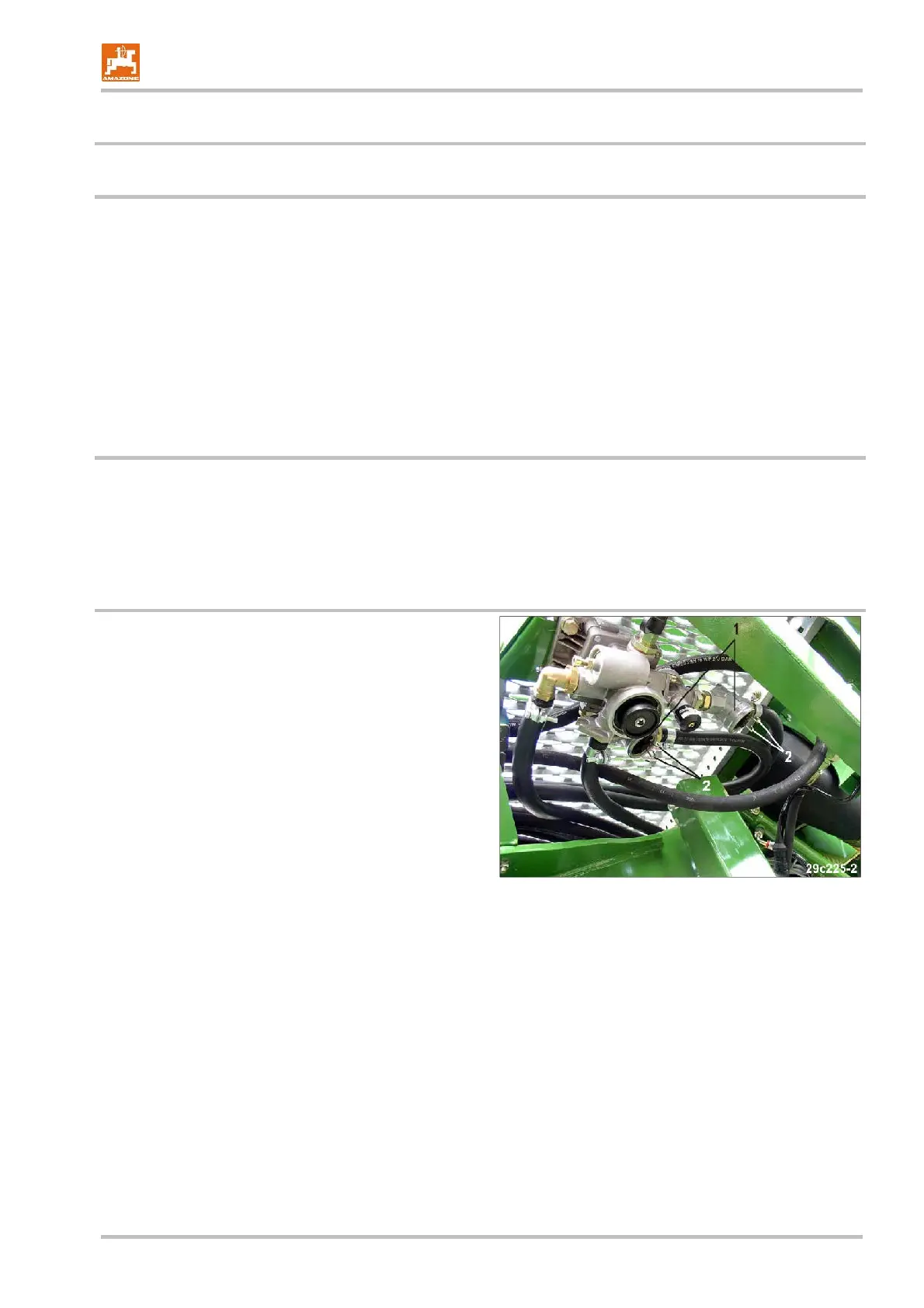

Clean the two hose filters (Fig. 241/1) every three

months (in difficult operational conditions more often) .

Proceed as follows

- press together the two straps (Fig. 241/2) and

remove the cap with O-ring, pressure spring and

filter insert.

- clean the filter insert by using petrol or diluting

agent (wash out) and dry with air pressure.

Reassemble in the vice versa order and be careful that

the O-ring does not get wedged in the guide slit.

Fig. 241

Loading...

Loading...