w

4. PREVENTIVE MAINTENANCE

No preventive maintenance is necessary for any

type

of FDDs under normal conditions of use.

However if it is determined

that adjustments are necessary, the

following

must be

done.

•

Adjustments (Refer to table

4.1)

(1)

Specify an applicable

model

from Table

4.1, and make a read/write head radial adjustment at a specified track.

(Sides

0,1)

(2)

Make an index timing adjustment

at a

specified track. (Sides

0,1).

(3)

Make an azimuth measurement

at a

specified track (Sides

0,1)

CAUTION

Do not write

when using alignment diskette. Check that write protect sensor is properly operating with

a data

diskette.

Note: Section

9

describes the adjustment procedures in detail.

5. ADJUSTMENTS AND VERIFICATIONS

5.1

Motor

Speed Verification (Index Period)

(1)

Insert

a

diskette, run

the motor, and clamp. Refer to the index period column of Table 4.1 for the applicable model.

(2)

Step to the specified track.

(3)

Connect

a

frequency counter

to

the INDEX signal.

IX (INDEX)

(4)

Check that the frequency

counter

readings

meet the specifications in the table.

5.2 Write Protect Verification

(1)

Check that the exerciser's write protect

lamp goes on and off as

a

media is inserted and removed

as

specified in the

table below.

Media with write protect hole open: ON

Media with write protect hole closed: OFF

5.3 Head Output Verification

Use a new diskette if possible to identify head failure for this check.

(1)

Insert

a good

diskette.

(2)

Run the motor.

(3)

Step to the track specified in the output level column of Table

4.1.

(4)

Connect the oscilloscope probe

as

specified below.

CH1 :

T1

CH2 : T2

EXT : IX (Index)

Invert channel 2 and select the Add

mode.

Set vertical deflection

to 10mV/division and horizontal deflection

to

20ms/division.

(5)

Write 2F

(all ones) on the entire circumference.

(6)

Check that

the average output level meets the specifications of Table 4.

1 .

If it

does not meet the spec-ifications, refer to item

7 of the Trouble Analysis Table.

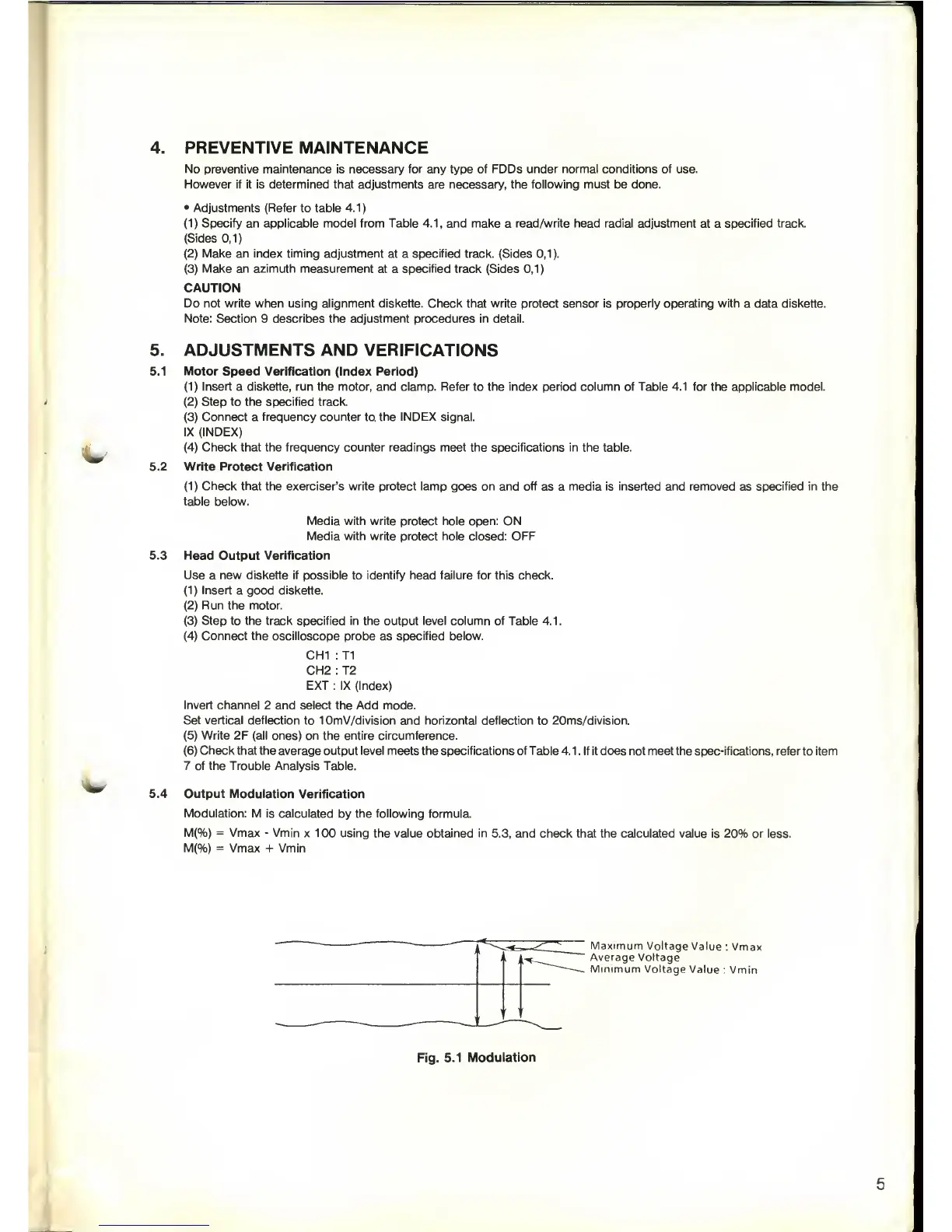

5.4 Output Modulation

Verification

Modulation: M

is calculated

by

the following formula.

M(%)

=

Vmax

-

Vmin

x 100 using the value obtained in

5.3,

and check

that the calculated value is 20% or less.

M(%)

=

Vmax + Vmin

i

'

'

,

]

1

1

'

1

Maximum

Voltage

Value

: Vmax

Average Voltage

Minimum

Voltage

Value

: Vmin

Fig.

5.1

Modulation

Loading...

Loading...