5.5

Radial Alignment Adjustment

Introduction

This adjustment

is

normally

not necessary.

If the mounting screws for the

steeper motor loosen, or if

parts become defective, or if

a

compatibility

error occurs, check

and

readjust according

to

the following

procedure.

Steps

(4)

and

(9)

below should

be

performed

regardless of the

type, CE

or

DAD

alignment

diskette

used. Use an alignment dis-

kette suitable to the

type

of FDD

to be adjusted according

to

table.

(1)

Insert an alignment

diskette.

CAUTION:

Be

sure

to leave the alignment diskette

under room conditions for 20 minutes

before adjustment.

(2)

Step to the track specified in the Radial

alignment column of Table 4.1.

(3)

Leave the oscilloscope

in the same condition

as mentioned in section 5.3.

•

Cats Eye System

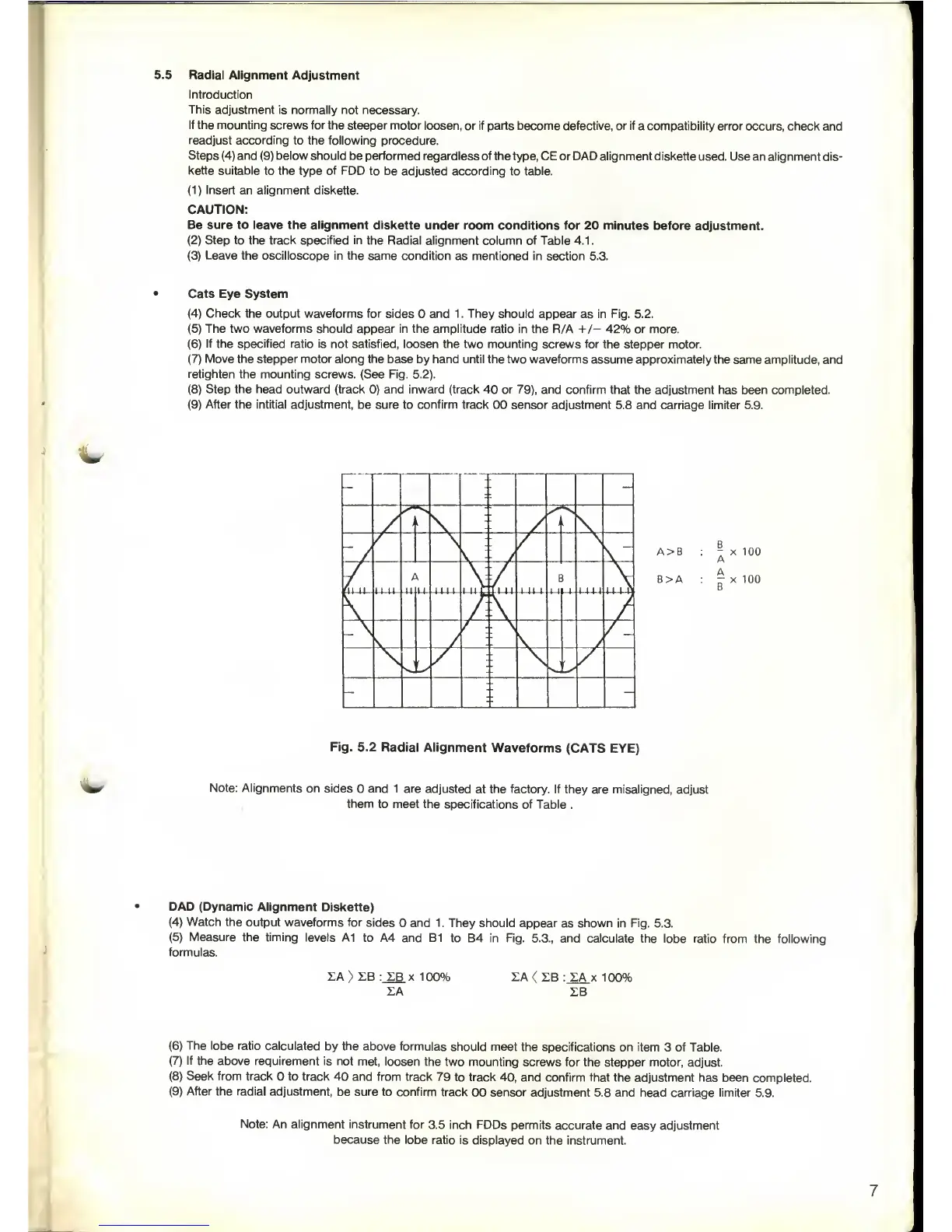

(4)

Check the

output

waveforms

for sides and 1. They should

appear as in Fig. 5.2.

(5)

The two waveforms

should appear in the amplitude ratio in the

R/A

+/-

42% or more.

(6)

If the specified ratio is not satisfied,

loosen the two mounting screws for the stepper

motor.

(7)

Move the stepper motor along the

base by

hand

until the two waveforms assume approximately

the same amplitude, and

retighten the mounting

screws. (See Fig.

5.2).

(8)

Step

the head outward (track

0)

and inward (track 40 or

79),

and confirm

that the adjustment has been completed.

(9)

After the intitial

adjustment, be sure to confirm track

00 sensor adjustment 5.8 and carriage

limiter 5.9.

- -

l

I

/

1

l

-

1

/

s.

-

U-44-

1,

U- III 1

i-W-C li-U- 1

II

1

E

-M

M

i-4-U

-

>

'

-

,1

'

'

- -

A>B

8>A

X 100

X 100

Fig.

5.2 Radial Alignment

Waveforms

(CATS EYE)

Note: Alignments

on sides

and 1 are

adjusted at the factory.

If they are misaligned,

adjust

them

to meet the

specifications of Table .

DAD (Dynamic

Alignment

Diskette)

(4)

Watch

the output

waveforms for sides

and 1. They should

appear

as

shown in Fig.

5.3.

(5)

Measure the timing

levels A1

to A4 and B1

to

B4 in Fig.

5.3.,

and calculate

the lobe ratio from

the following

formulas.

LA

>

SB ZB x 100%

LA

LA

( SB : LA x 100%

SB

(6)

The lobe ratio calculated

by

the

above formulas

should meet the

specifications on item

3

of

Table.

(7)

If the above

requirement is not

met, loosen

the two mounting

screws for the stepper motor,

adjust.

(8)

Seek from track

to track

40

and from

track 79

to track

40,

and confirm that

the adjustment has

been completed.

(9)

After the radial

adjustment, be sure

to confirm track

00 sensor adjustment

5.8 and head carriage limiter 5.9.

Note: An

alignment instrument

for

3.5 inch FDDs permits

accurate and

easy

adjustment

because the lobe ratio

is displayed

on the instrument.

Loading...

Loading...