Installation of the HPX Base Assembly

The following sections describe the preparation, installation and setup of

the HPX-600/900/1200 Hydraport Base Assembly. A typical installation will

include several various HPX modules.

Note: Refer to www.amx.com for a complete listing of compatible

HydraPort Connection Modules.

Each HPX module has specific instructions for terminating their

connections. Refer to each HPX Module’s Installation Guide during the

installation of the Hydraport system.

Note: Read these instructions in their entirety before beginning the

installation. The installation requires specific steps to be performed

in specific order.

CAUTION: This installation requires specific woodworking skills. This

installation should be performed by an experienced person,

comfortable with these types of woodworking operations. Improper

installation may result in damage to the mounting surface. AMX is not

responsible for damage caused by improper installation.

1) Select a Suitable Location for the HPX Base Assembly

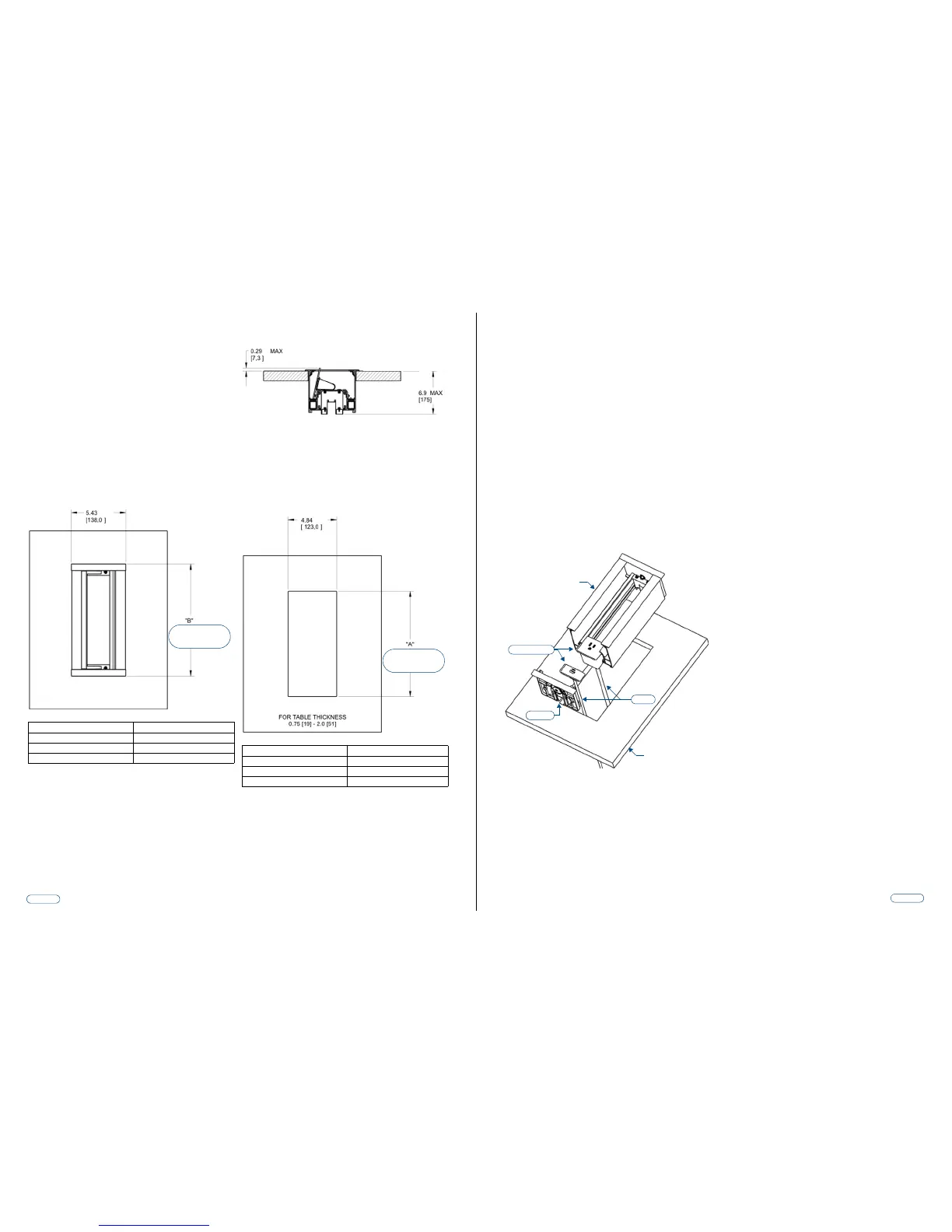

The following figures (FIG. 2 & FIG. 3) indicate the space requirements for

installing the HPX Base Assembly:

FIG. 3 indicates the dimensions above the table:

• The Hydraport system requires a mounting surface from 0.5” (13mm)

to 2” (51mm) thick.

• The Hydraport system requires at least 6 15/16" (175 mm) below the

mounting surface.

Note: Care should also be taken to ensure that the Hydraport system does

not interfere with the normal use of the work space. For example, on a table

or work surface, ensure that the system does not interfere with the user's

legs when they are seated at the table.

2) Cut the Hole In the Mounting Surface

FIG. 4 provides the Hole cutout dimensions for the HPX Base Assembly:

1. Carefully measure the tabletop or other mounting surface to locate the

desired position of the HPX Base Assembly.

2. Use the cutout template supplied with the HPX Base Assembly to

mark the edges of the cutout.

FIG. 2 Dimensions of the HPX Base Assembly (above the table)

Model Length of “B”

HPX-1200 (Holds up to 12 HPX Modules) 14.09” (358 mm)

HPX-900 (Holds up to 9 HPX Modules) 11.14” (283 mm)

HPX-600 (Holds up to 6 HPX Modules) 8.19” (208 mm)

See table below for the

length of “B” for each

HPX model

FIG. 3 Dimensions of the HPX Base Assembly (below the table)

FIG. 4 HPX Base Assembly - Hole cutout dimensions

Model Length of “A”

HPX-1200 (Holds up to 12 HPX Modules) 13.54 (344 mm)

HPX-900 (Holds up to 9 HPX Modules) 10.59 (269 mm)

HPX-600 (Holds up to 6 HPX Modules) 7.64 (194 mm)

See table below for the

length of “A” for each

HPX model

Note that very little clearance exists between the HPX Base Assembly and

the hole cutout in the mounting surface.

• Take care to align the cutout carefully with the edges or other

appropriate features in the table or mounting surface.

• If the cutout is misaligned, the installed unit will be misaligned.

• Take care to ensure that the top surface of the mounting surface is not

damaged beyond the width of the trim bezel as the cutout is made.

• Use an appropriate drill and drill bit to make a starting hole within the

boundary of the cutout. Use an appropriate saw, such as a jigsaw to

finish the cutout.

• Make sure cutting tool used is appropriate for the material to be cut

and will not tear or chip the top surface.

• Note that the process of making the cutout will create substantial dust

and prepare the environment appropriately.

3) Prepare the Terminations

Some modules that are included in the final system require some type of

backside termination.

Note: Refer to the installation guide for each module to determine the

required backside termination.

• The backside termination for each module can and should be

completed before the module is installed into HPX Base Assembly.

• For terminations for which the far end of the cable is not accessible

(either because the cable has been run under carpet, in a conduit or

structure, or is otherwise fixed), the cable must be placed through the

cutout in the table prior to installation, as indicated in FIG. 5.

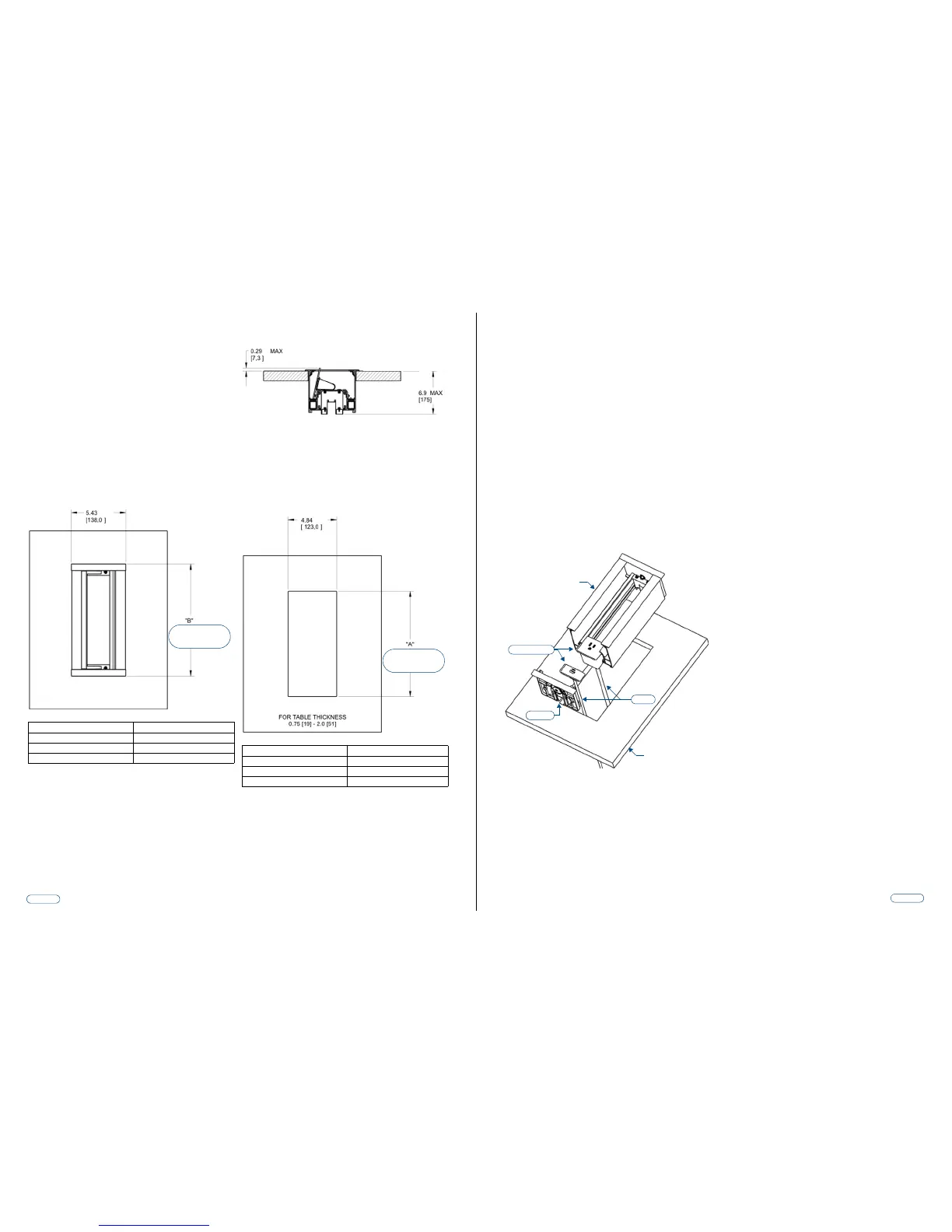

4) Insert the HPX Modules

Note the orientation of each HPX Module - a small tab exists on one side of

the faceplate of each module. Ensure all tabs are facing the same direction

(see FIG. 5).

1. Remove one end cap of the HPX Base Assembly by removing the six

sheet metal screws and one pivot screw and pivot pawl assembly.

2. Slide the pre-terminate modules one at a time into the HPX Base

Assembly.

3. Rout the cables from each module out the bottom of the HPX Base

Assembly.

4. Use cable ties and one or more of the sliding clips to secure the

cables as needed to the HPX Base Assembly.

5. Reinstall the end cap of the HPX Base Assembly by installing the six

sheet metal screws and one pivot screw and pivot pawl assembly.

Note: Do not over-tighten the pivot pawl screw (i.e., do not use a high-

powered drill to tighten this screw).

FIG. 5 Inserting the Modules into the Assembly

Interlocking tab

Cables

HPX Base Assembly

Mounting Surface

End Cap

Loading...

Loading...