13

Step 13: Select the appropriate belts for your chassis configuration, and loop one belt over each Pulley on each

Center Wheel Assembly.

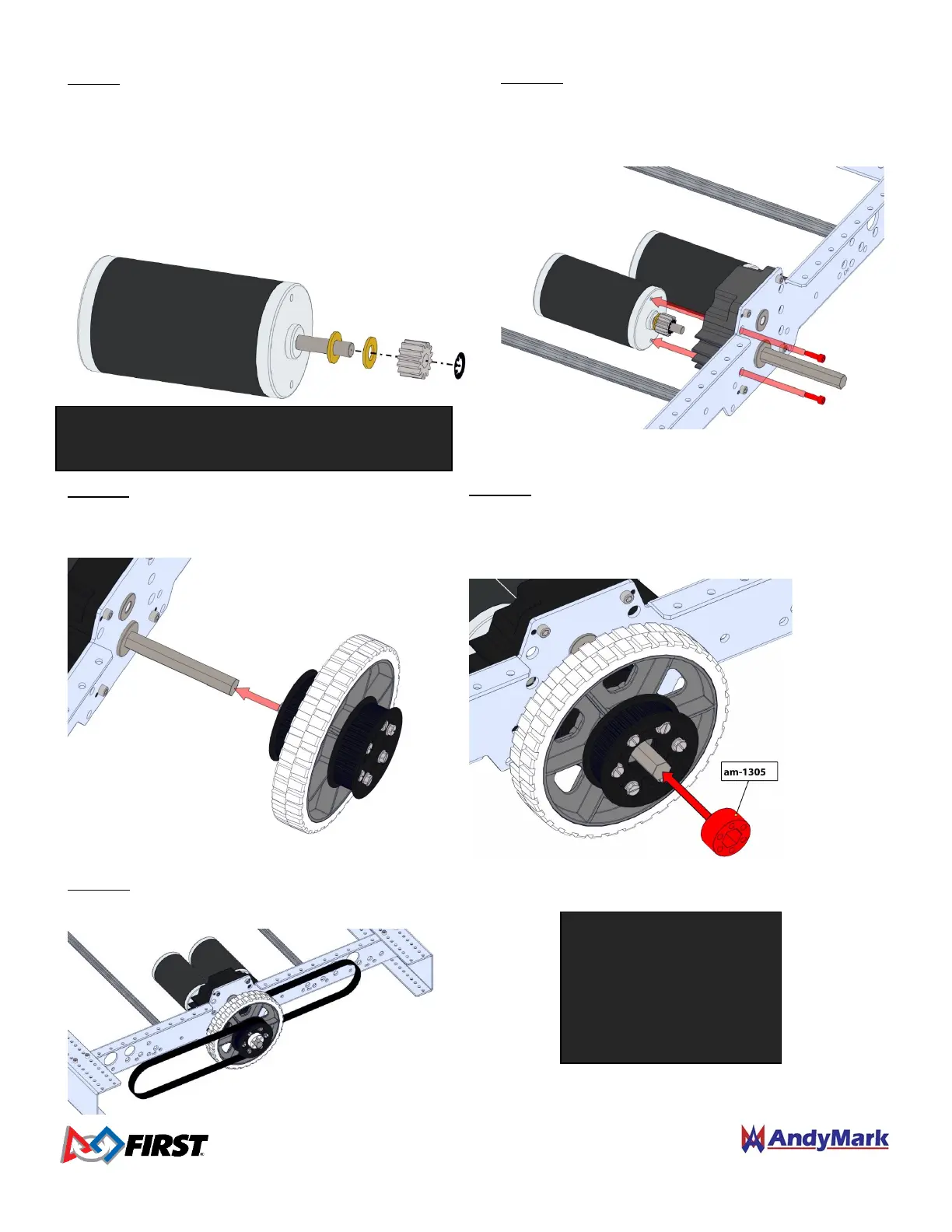

Step 9: Slide two 5/16” washers (am-1009) onto each CIM

motor shaft against the round boss of the motor. Place

the Machine Key (am-1121) into the keyway of the motor

shaft. Slide the 14 tooth (am-0034) gear onto the shaft up

to the washers, while aligning the keyway of the gear to

the key. Use a 7/16” socket to press the 8mm Retaining

Clip (am-0033) onto the face of the gear, with the tabs of

the clip pointing toward the motor shaft.

Line up the CIM motors with the mounting

holes in each Toughbox Mini. Secure each motor with

gears installed to the Toughbox Mini housing using

two 10-32 x 0.625” SHCS w/ Nylon Patch (am-1120).

The long chassis requires 160

tooth belts (am-2266).

The wide chassis requires 120

tooth belts (am-2704).

The square chassis requires

131 tooth belts (am-2571).

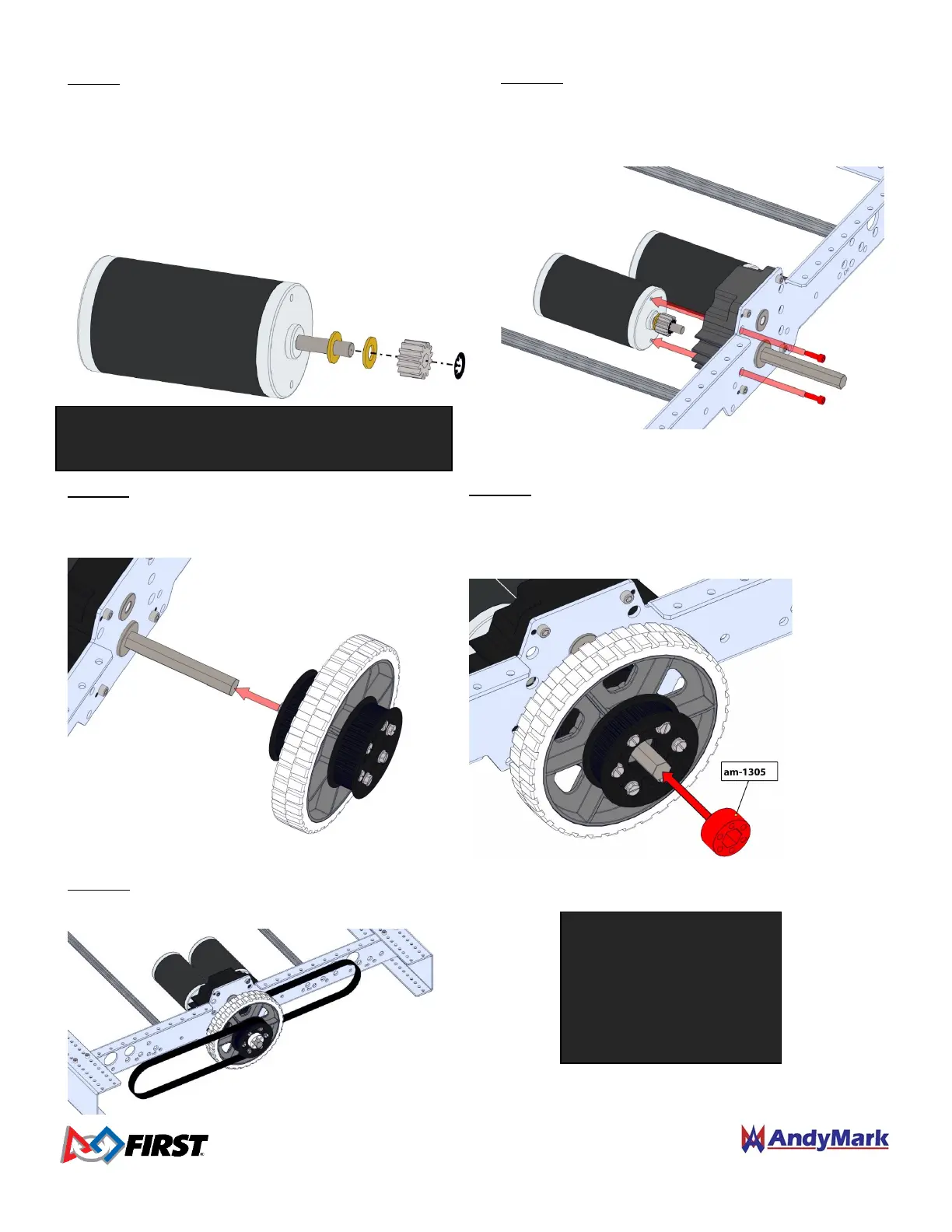

Step 12: Place the Hex Spacer (am-1305) onto each

Toughbox Mini Hex Output Shaft and press into the round

cavity in the pulley. The shaft will help align the spacer

hex bore with the wheel hub hex bore.

Step 11: Place a Center Wheel Assembly onto each

Toughbox Hex Output Shaft with the aluminum

hub facing towards the Inside Plate.

NOTE: Each drive gearbox can accept up to 2

motors. Repeat this step for each motor.

Loading...

Loading...