50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Form No.V8714 - Sec. 1

Page 4 of 6 (Section 1 of 2)

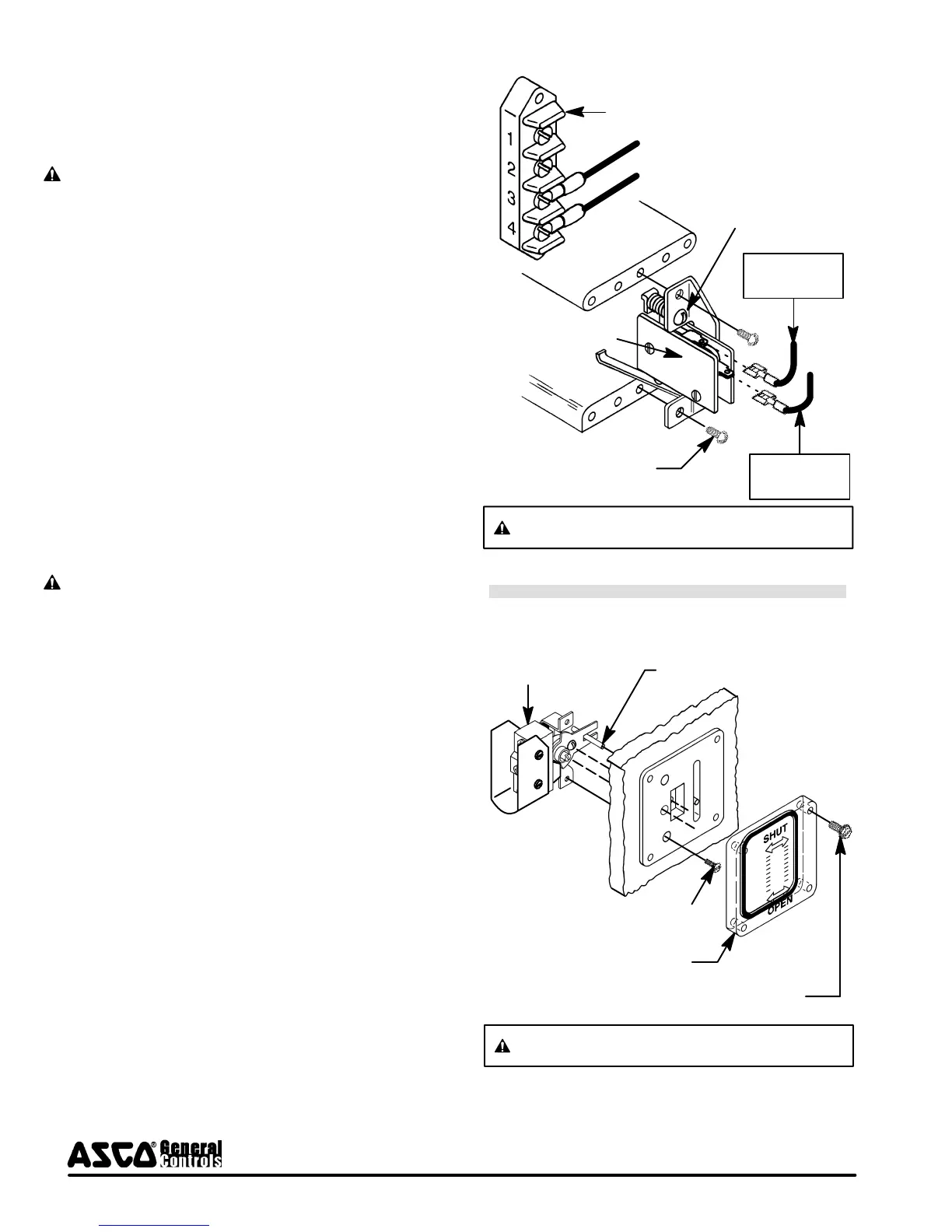

Travel Limit Switch Replacement (Refer to Figure 5)

1. Remove the six cover screws and nameplate/electrical

cover with gasket.

2. Disconnect wiring from travel limit switch.

CAUTION: Label wires before disconnecting.

3. Remove two mounting screws and the travel limit switch.

4. Reinstall new travel limit switch in actuator. Torque

mounting screws (2) evenly to 20 to 25 in-lbs [2,3 to 2, 8

Nm].

5. The required stroke is 1 1/8 1/16. Turn adjustment

screw located above limit switch until the desired stroke

is achieved. Turn the adjustment screw clockwise to

decrease stroke and counterclockwise to increase stroke.

6. Operate actuator (complete system) through five cycles to

verify proper operation.

7. Reinstall nameplate/electrical cover with gasket and

screws (6) on actuator housing. Hand thread screws as far

as possible, then torque screws evenly in a crisscross

manner to 30 to 35 in-lbs [3 ,4 to 4, 0 Nm].

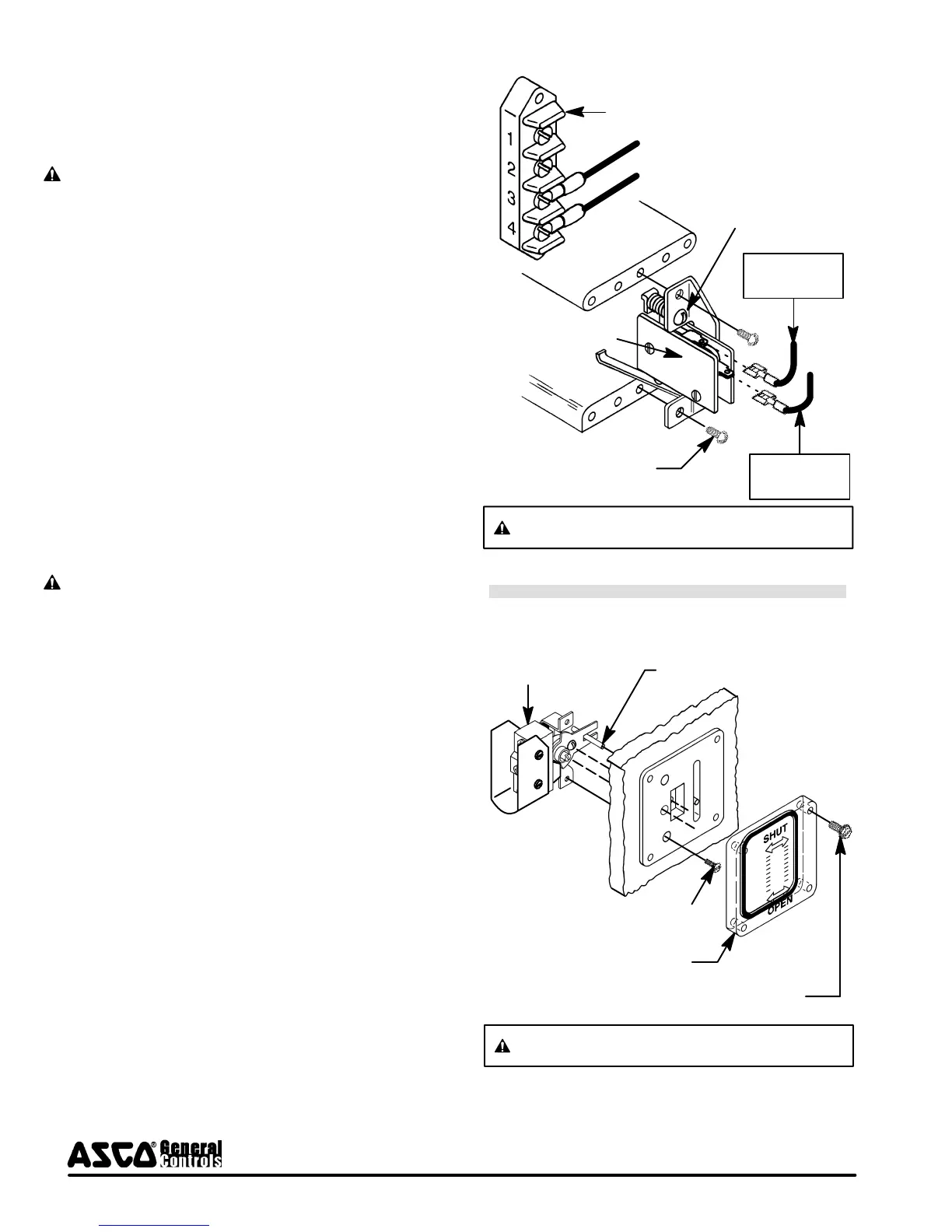

Auxiliary Switch Replacement (Refer to Figure 6)

1. Remove six cover screws and nameplate/electrical cover

with gasket.

2. Disconnect auxiliary switch wiring.

CAUTION: Label wires before disconnecting.

3. On auxiliary switch side of actuator, remove window

screws (4) and window with gasket.

4. Remove auxiliary switch mounting screws (2) from side of

actuator.

5. Disengage auxiliary switch from indicator bar and remove

switch from actuator.

6. Install new auxiliary switch and reassemble in reverse

order of disassembly.

7. Torque auxiliary switch mounting screws (2) evenly to 14 to

16 in-lbs [1, 6 to 1,8 Nm].

8. Torque terminal screws 8 to 12 in-lbs [0, 9 -1, 3 Nm].

9. Reinstall the window with gasket and torque screws

evenly to 14 to 16 in-lbs [1,6 to 1,8 Nm].

10. Reinstall nameplate/electrical cover with gasket and

screws (6) on actuator housing. Hand thread screws as far

as possible, then torque screws evenly in a crisscross

manner to 30 to 35 in-lbs [3 ,4 to 4, 0 Nm].

11. Operate actuator (complete system) through five cycles to

verify proper operation.

Figure 5. Travel Limit Switch Replacement.

Main terminal

Travel limit switch

Adjustment screw

Mounting screw (2)

Partial Cutaway View

Connect to

Terminal 3

Connect to

Terminal 4

CAUTION: Label wires before disconnecting.

Figure 6. Auxiliary Switch Replacement.

Auxiliary switch

Position indicator bar

Switch mounting screw (2)

Partial Cutaway View (Right Side)

Window with gasket

Window screw (4)

CAUTION: Label wires before disconnecting.

Continued on Form No. V8714-Section 2.

Loading...

Loading...