might be necessary to open a window to provide air for combustion and to equalize the vacuum.

Alternatively, you could fit an air vent in the room containing the wood burning stove.

4.0 The chimney

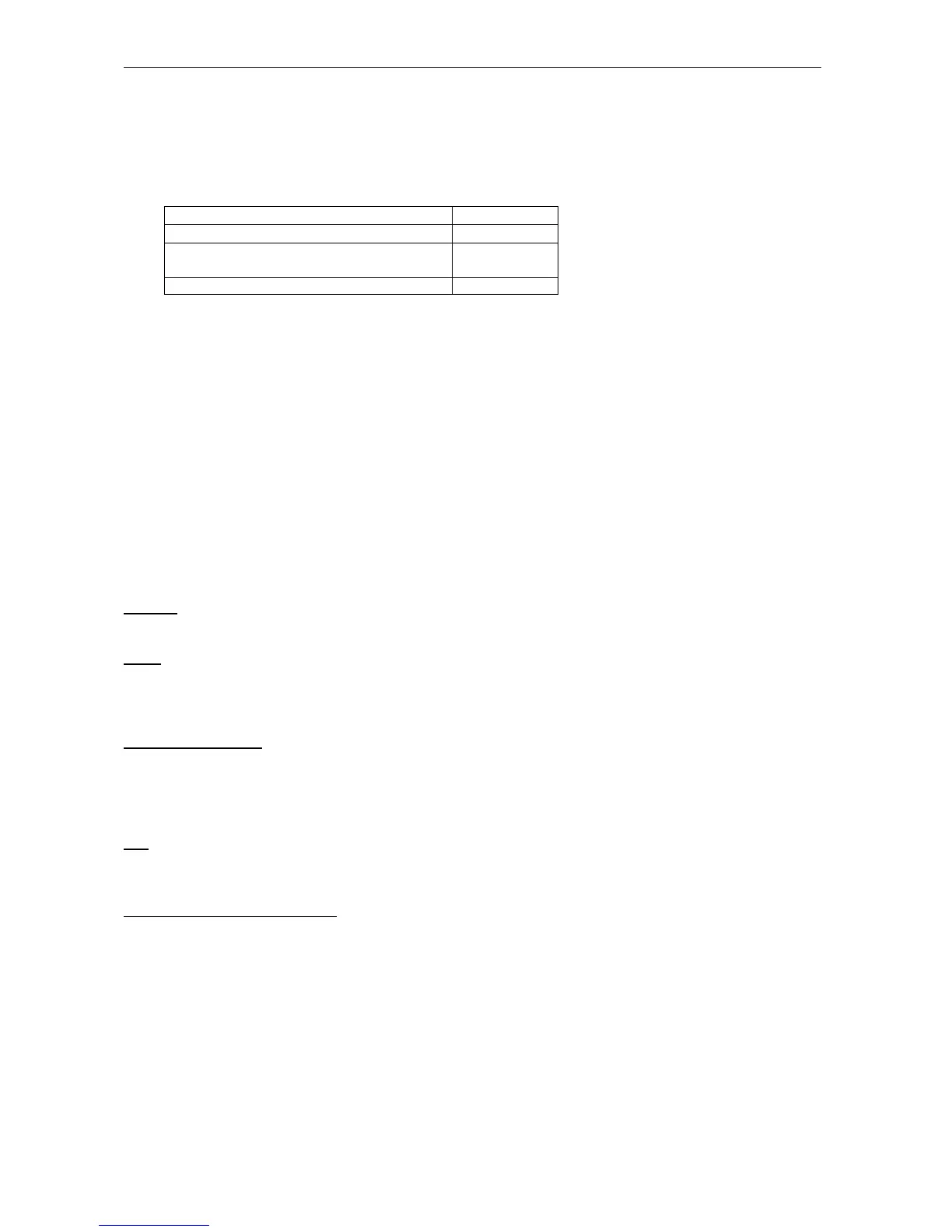

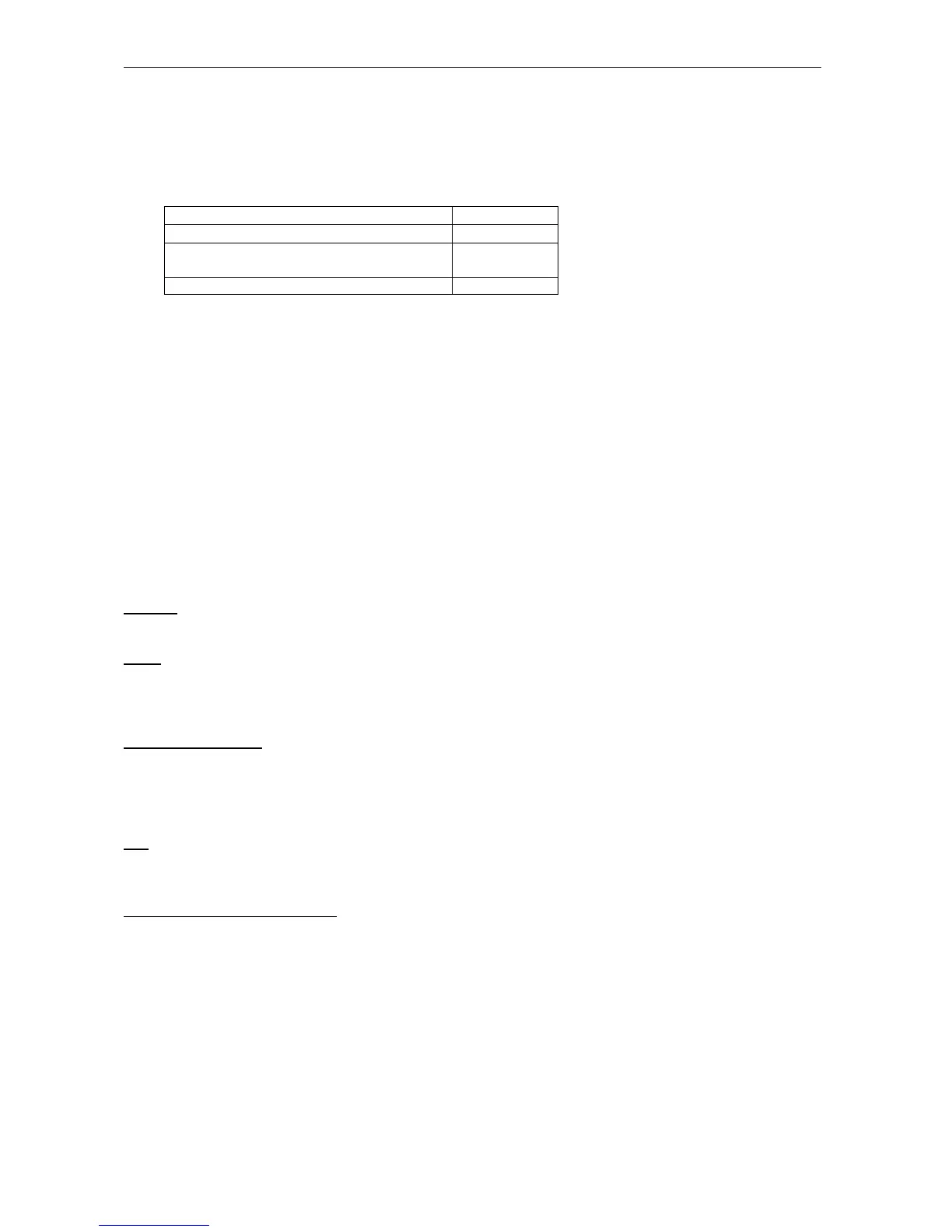

Data for chimney calculation:

Wood

Flue temperature at [20 °C]

367

Chimney draught at testing power

[mbar]/[Pa]

0.12/12

Flue gas mass flow [g/s] 4,0

The optimum combustion is achieved at a constant chimney draught of 0.10 to 0.14 mbar measured in the

flue pipe above the stove. There are many factors that affect the chimney draught, including the outside

temperature, wind strength and surrounding buildings. If it is impossible to establish a sufficiently natural

chimney draught, the chimney can be fitted with a smoke extractor. If the chimney draught is too strong, a

damper can be fitted to regulate the chimney draught. Contact your local chimney sweep for more advice.

4.1 Inadequate draught in the chimney

If the chimney is too short, leaks or is inadequately insulated, there may be problems with the chimney

draught (let the chimney sweep assess this). The draught should be approx. 0.10–0.14 mbar in order to

provide satisfactory combustion and prevent smoke leakage.

If the chimney sweep judges the draught to be satisfactory, but you still have problems lighting a fire, try

extending the fire lighting phase/using more thin pieces of kindling, so that the chimney gets thoroughly

warm. The chimney will not draw at optimum effect until it is warm. The fire lighting phase can be prolonged

by using a lot of kindling and 1-2 firelighters. When a layer of embers has been formed, add 2–3 dry logs.

5.0 Maintaining and cleaning your wood burning stove

Gaskets

With time, the gaskets will wear, and, in order to avoid wild combustion, they must be replaced as required.

Glass

If the wood you burn is too moist, you will get soot stains on the glass pane. They can be easily removed

using a damp cloth that you dip in cold ash and rub on the sooty glass. Special cleaning agents are also

available to remove soot from glass.

Combustion chamber

The yellow tiles in the combustion chamber eventually wear out and they should be replaced when the

cracks are more that 0.5 cm. The durability of the tiles will depend on how often and how intensively the

stove is used. You can change the tiles yourself. They are available as a ready-to-use set. You can also buy

one-piece tiles that you can cut to the size of the worn plates yourself. Please consult your dealer.

Ash

Empty the ash drawer before it becomes completely full. Always leave a layer of ash on the bottom of the

stove, as this insulates the combustion chamber and makes lighting a fire easier.

Cleaning the wood burning stove

The stove’s surface is treated with a heat-resistant Senotherm® paint, which will stay at its best just by being

vacuumed with a small, soft mouthpiece or dusted with a soft, dry cloth. Do not use spirit or other solvents

which will remove the paint.

The inside of the wood burning stove and the flue pipe can be cleaned via the door and the cleaning

aperture in the flue pipe/chimney. The upper fireproof tile (the exhaust deflector) can be removed, allowing

access to the top of the wood burning stove. Cleaning of the inside of the wood burning stove and the flue

pipe should be undertaken at least once a year, or more frequently if necessary, depending on how often the

wood burning stove is used. This work can also be carried out by the chimney sweep.

Loading...

Loading...