IB-2003

eries 40 Trans

ite -

tationary

onveyor

40

Conveyor Belt

Using tail pulley for belt

training will cause serious

damage to the belt and

idlers.

Belt Training

Initial installation of the

conveyor belt should ensure

good alignment of pulleys,

troughing and return idlers.

They should be placed at

right angles to the direction of

travel, leveled and centered on

a straight line.

The fi rst movement of the belt

should be slow and intermittent

so that any tendencies of the

belt to run off may be quickly

observed and the belt stopped

before damage occurs.

Initial movement of the belt

will provide indication of where

corrections are required. The

fi rst corrections must be at

points where the belt is in

danger of being damaged.

Once the belt is clear of all

danger points, a sequence

of training operations can be

followed.

The best procedure to use in

starting the training sequence

is to start with the idler closest

to the tail pulley on the return

run and work toward the head

pulley.

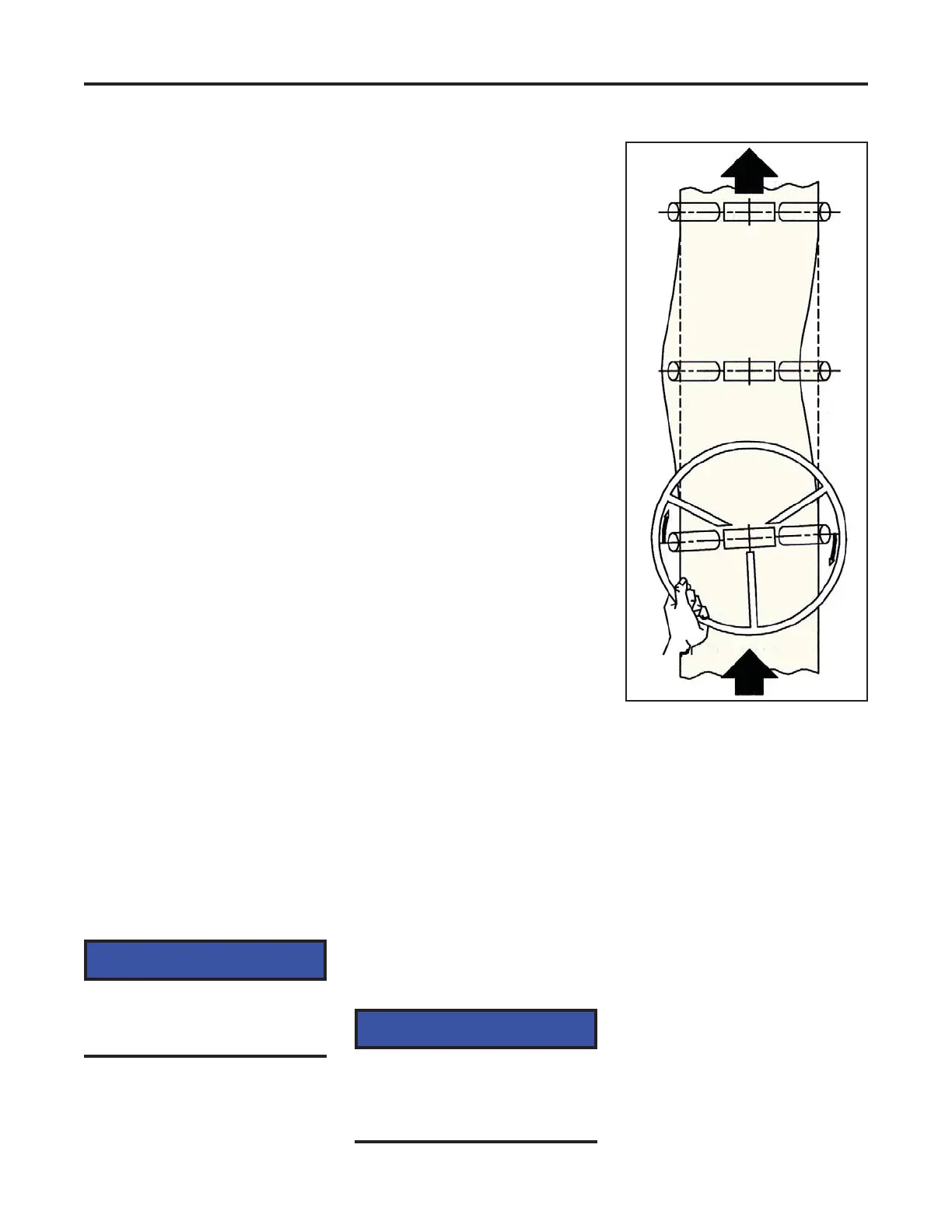

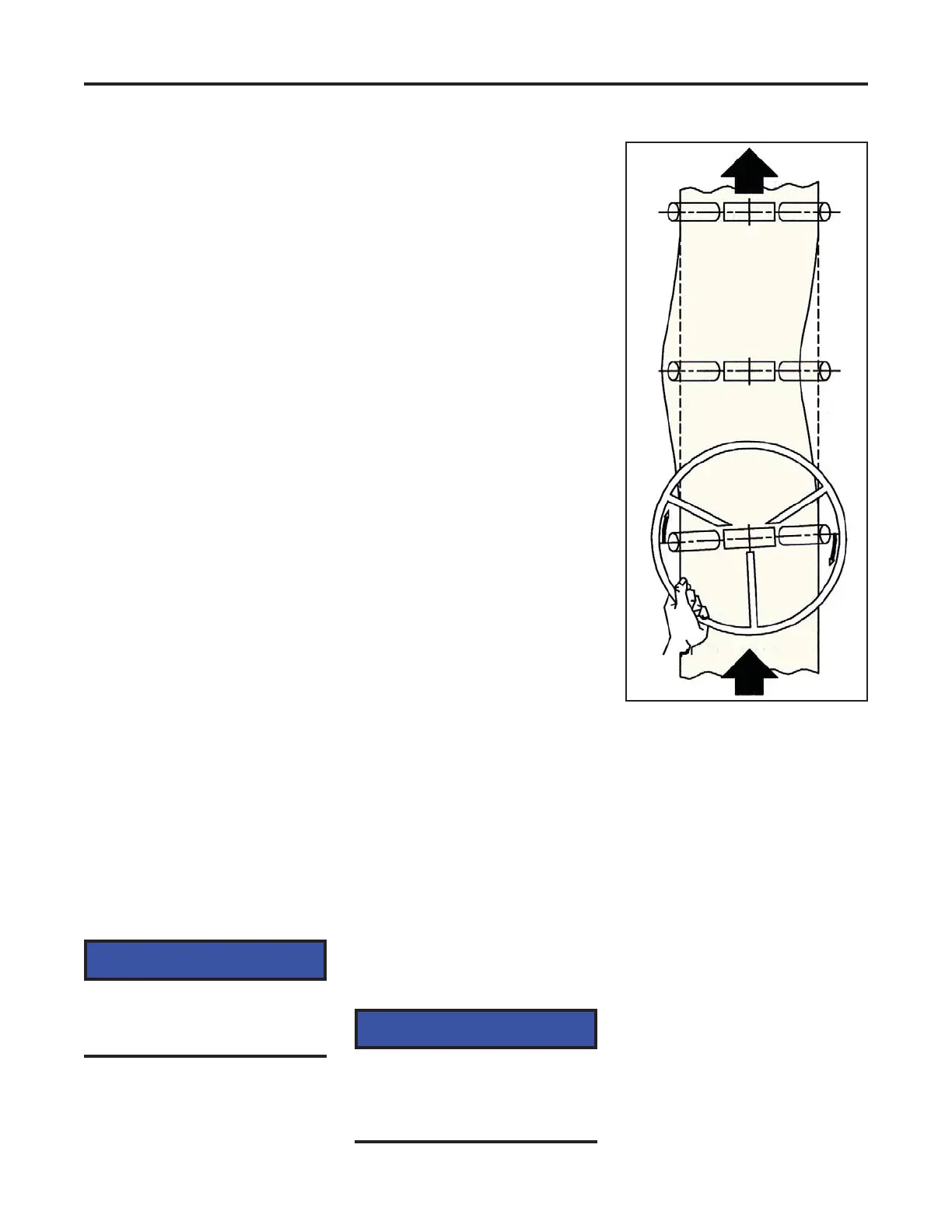

Direction of Belt Adjustment

Belt Cleaning

Special care must be exercised

to keep the return rolls and

snub pulleys clean. Buildup

of material on this equipment

has a destructive effect on belt

training which can cause the

belt to run against the structure

and be damaged.

Refer to the belt cleaner

manual included with conveyor

for more information.

1. Idlers should be clear of dirt

and any material.

2. Check conveyor frame for

level.

3. Check to make sure idlers

are square to the direction

of belt travel.

4. Check belt splice for

squareness.

5. Work from idler to idler in

the opposite direction of

belt travel.

6. Shift only one idler at a

time (shifting subsequent

idlers may cause

overcorrection).

7. Make slight adjustments

rather than extreme ones.

8. Wait for at least three belt

revolutions before making

further adjustments.

9. Never adjust pulleys for belt

training. Pulleys should be

kept square to belt travel

and should only be altered

when other methods have

failed.

10. Apply the “steering wheel”

principle to each of the

idlers when making

adjustments.

With the empty belt trained

satisfactorily, good operation

with load is assured.

Disturbances which appear

with load are usually due to

off-center loading or to the

Do not adjust while belt

is running. Use correct

lockout/tagout procedure.

NOTICE

Use the following steps:

NOTICE

accumulation of material from

the load on pulleys or idlers.

Loading...

Loading...