Flight and Operations Manual of ATEC 321 Faeta ultralight aircraft with Rotax 912 iS Sport

ATEC v.o.s. Libice nad Cidlinou, Czech Republic Page 47 of 56

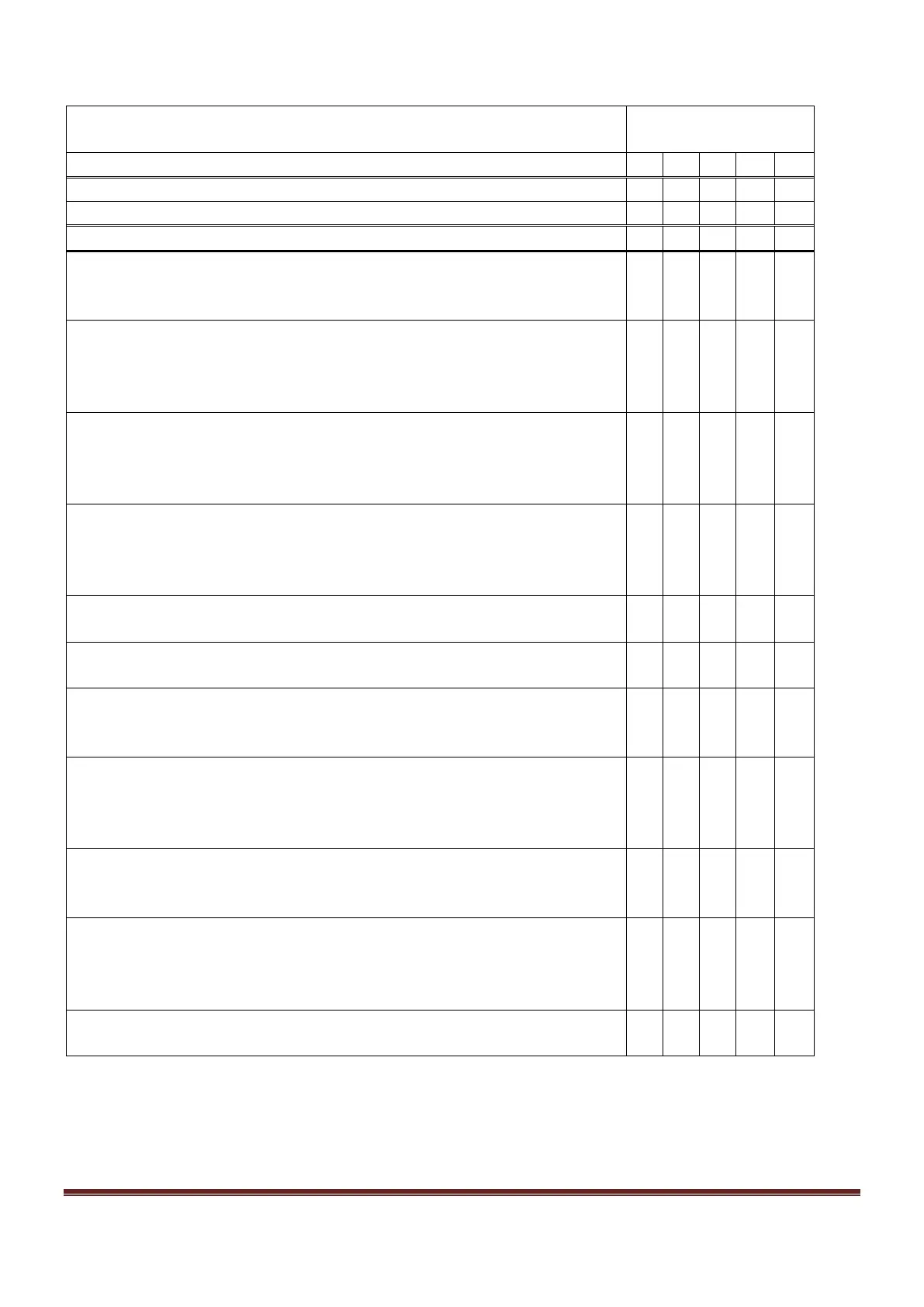

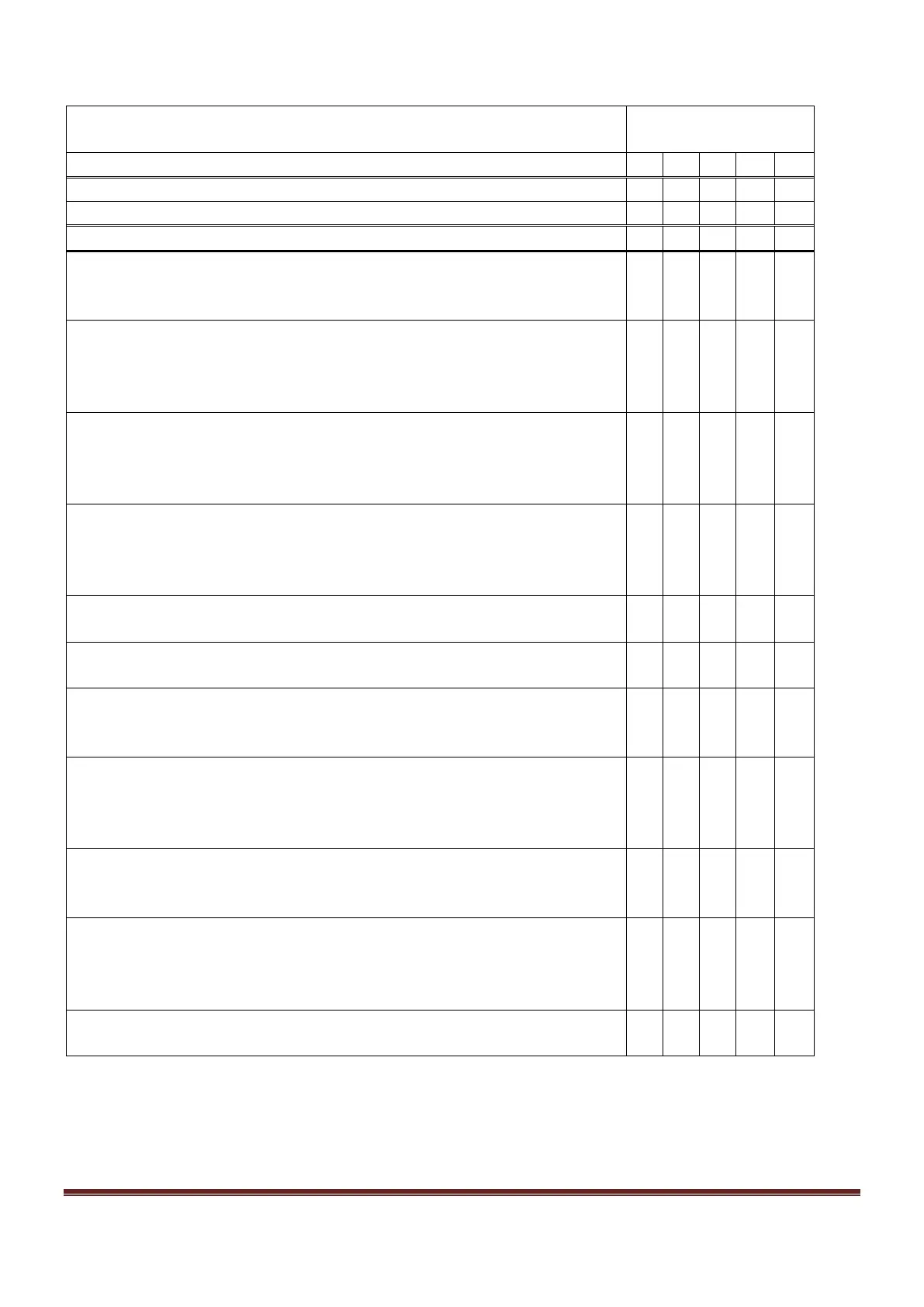

9.1. Maintenance Schedule

Inspection, Mandatory Work

Inspection Period

(hours)

As per ROTAX Manual attached.

Engine Bed

Check integrity of construction with a special focus on welds, fixing

points, silent blocks, bushings. Check surface condition.

Bolted Connections

Check surface condition of bolted connections, bearing surfaces. Check

securing and tightening. Tighten and re-secure if necessary. Replace

locking nuts, split pins and securing wires.

Silentblocks

Check elasticity of engine bearing, integrity of rubber blocks, degree of

permanent deformation. Replace silent blocks if necessary, tighten,

secure.

Oil, Coolant and Fuel Hoses

Check surface integrity, leakage, clamps tightness, condition of

connections, protection avoiding touching with oscillating parts and

exhaust system. Re-tighten or replace if necessary.

Operating Liquids

Check level, refill according to instructions of the engine producer.

Coolers

Check integrity, sealing, purity.

Controls

Check forces, end stops adjustment, plays, hinges, self-locking. Adjust,

secure.

Exhaust piping

Check attachment, integrity, sealing, surface condition, corrosion

degree, springs condition and pre-stress. Grease ball connections by a

special lubricant.

Injection

Check the condition of hoses, connectors and electric cables of

individual nozzles.

Electric Installation

Check integrity, purity and general condition of cables, insulation,

contacts, soldered joints, wiring harness attachment to the airframe and

bushings. Check probes and indicators interconnection.

Propeller Attachment

Check condition of bolts, torques, securing.

Loading...

Loading...