Operation and maintenance manual - EN

EN

www.atmos.cz

EN-51

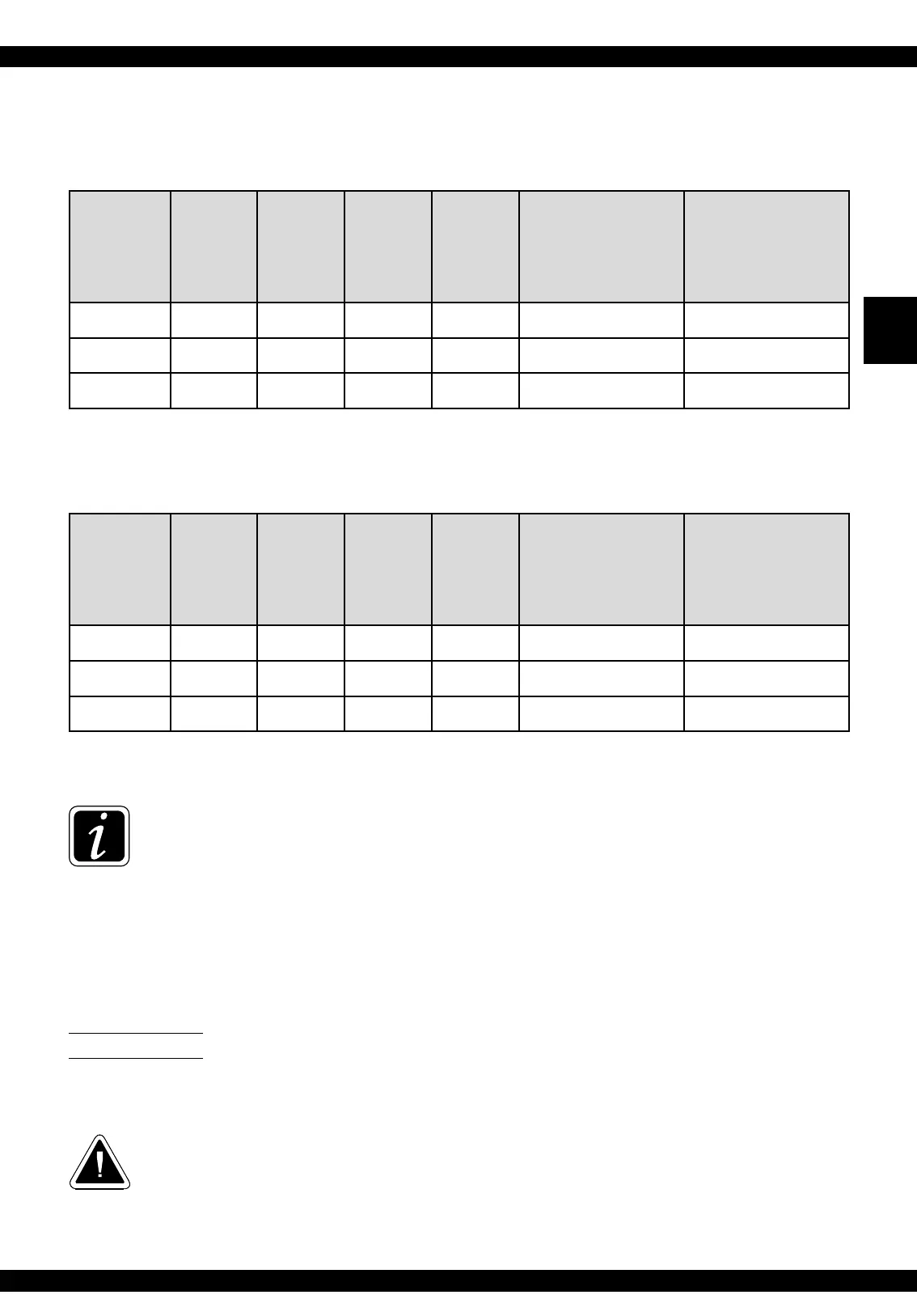

Recommended approximate setting of the burner with the use of DA1500, DA2000, DA2500,

DA3000 and DA4000 conveyors, for individual output values and pellets with the diameter of

6 mm and conveyor angle of 45°:

Boiler

output

Parameter

T1

Parameter

T4

Parameter

T6

Parameter

S3

Opening of the air

ap on the burner

fan of a boiler

with

an exhaust fan

Opening of the air

ap on the burner

fan of a boiler

without

an exhaust fan

10 – 12 kW 100 s 6 s 11 s 70 % 1/4 (12 mm) 1/2 (25 mm)

15 – 16 kW 100 s 8 s 10 s 100 % 1/4 (14 mm) 2/3 (37 mm)

20 – 24 kW 100 s 12 s 8 s 100 % 1/2 (27 mm) 3/4 (42 mm)

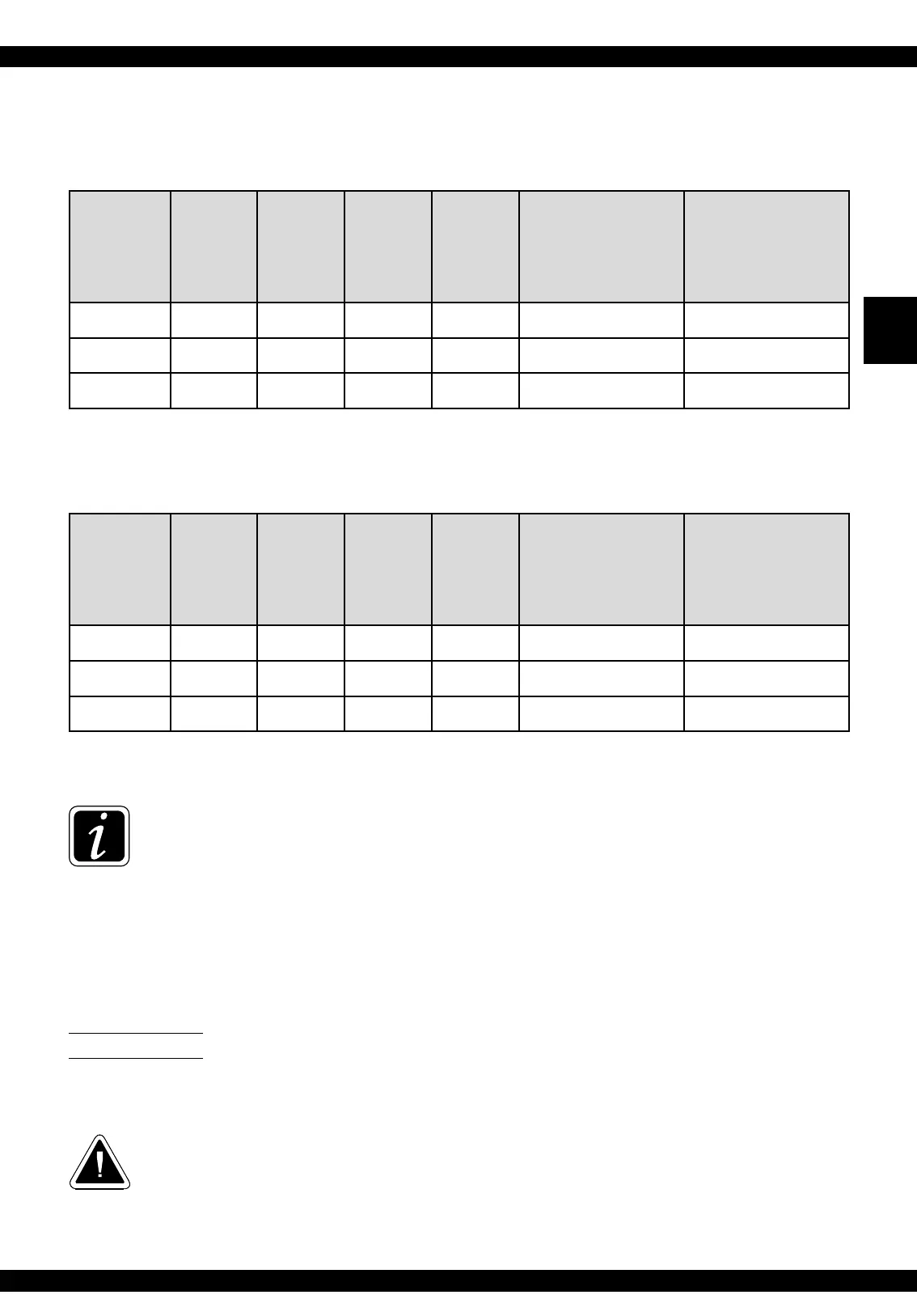

Recommended approximate setting of the burner with the use of DRA25 1,3 m and DRA25 1,7

m conveyors , for individual output values and pellets with the diameter of 6 mm and conveyor

angle of 65° (compact pellet tanks AZPU and AZPD):

Boiler

output

Parameter

T1

Parameter

T4

Parameter

T6

Parameter

S3

Opening of the air

ap on the burner

fan of a boiler

with

an exhaust fan

Opening of the air

ap on the burner

fan of a boiler

without

an exhaust fan

10 – 12 kW 60 s 3 s 15 s 70 % 1/4 (12 mm) 1/2 (25 mm)

15 – 16 kW 60 s 3 s 13 s 100 % 1/4 (14 mm) 2/3 (37 mm)

20 – 24 kW 60 s 3 s 10 s 100 % 1/2 (27 mm) 3/4 (42 mm)

Burner settings for DxxPX and PXxx boilers follow instruction manual for this boilers.

INFO – If the boiler power is lower than 15 kW, switch off the extraction fan on the boiler

by removing the connector of the extraction fan from the boiler hood. This does not apply

for boilers with burner built in the upper doors and boilers DxxPX, PXxx where the

exhaust fan must always be running with the pellet burner. If necessary, if there is a

limited space in the boiler room, you can shorten the length of the conveyor (worm) or its

leg any time as desired, but the angle of the conveyor should never exceed 45°.

Minimum length of hose between the burner and the conveyor must be bigger than 20 cm.

Maximum hose length should not be more than 1 m.

• Parameter S1 – Allowed number of attempts for ignition with fuel supply… (2).

If parameter S1 is set to 4, the fuel will always be ignited with both the ignition elements at

the same time (Z1 + Z2) in 2 attempts for ignition with fuel supply.

CAUTION - Always after the last attempt for ignition with fuel supply given by parameter

S1, an attempt for ignition without fuel supply will follow to test the equipment. If the fuel

is not ignited after this attempt, the system will be put out of operation and the ALARM

START error message will appear.

Loading...

Loading...