10

Joining technology

The key to optimizing the body structure is using "the right

materials in the right place". The resulting challenge for

the joining technology was to develop universal and reliable

solutions for the large variance in material/thickness com-

binations in the body. On the TT, Audi uses "cold" joining

techniques such as riveting, ow-drill screwing and clinch-

ing to create the aluminum/steel hybrid structure.

Adhesive is also used to strengthen the connection and to

prevent contact corrosion of the aluminum/steel joint.

The body is constructed using the following types of joining

methods:

• 3020 spot welds.

• 1113 punch rivets.

• 44 solid punch rivets.

• 128 ow-drill screws.

• 199 clinching points.

• 6.23 ft (1.9 m) of MIG/MAGwelds

(metal inert gas/metal active gas).

• 16.07 ft (4.9 m) of laser-welded seams.

• 249.34 ft (76 m) of adhesive.

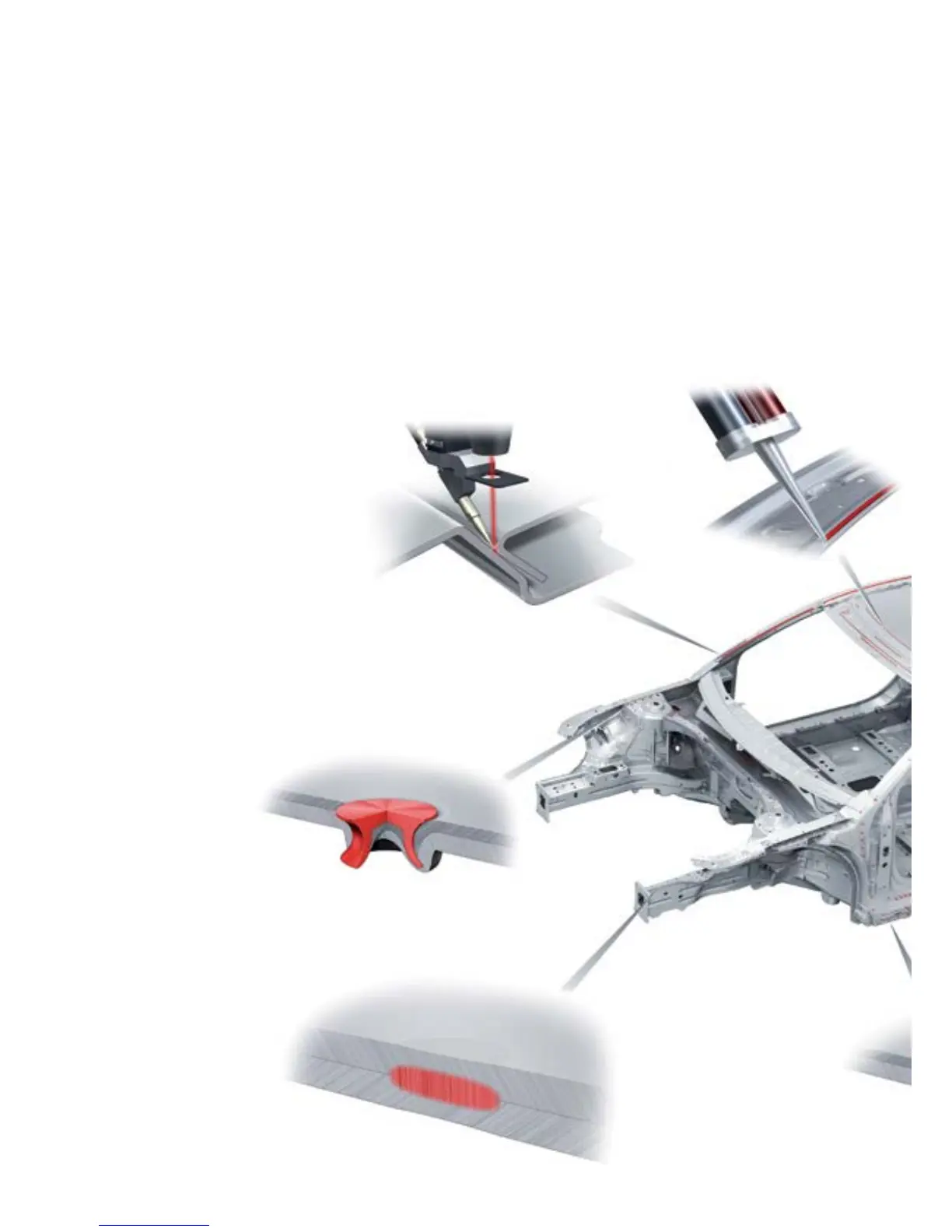

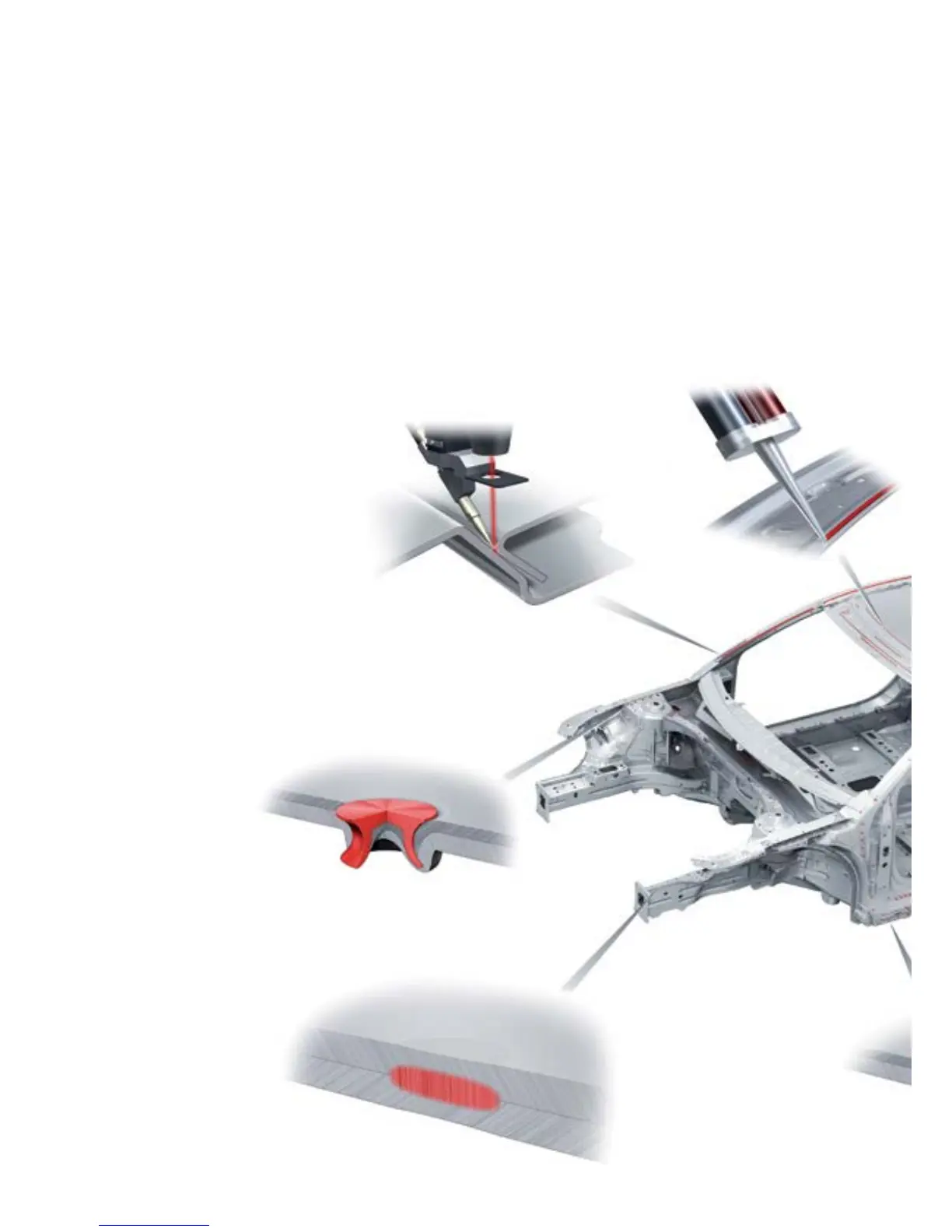

Joining methods used on the Audi TT

Laser welding

Bonding

Resistance spot welding

Semi-tubular punch riveting

Loading...

Loading...