4.Use and Ooeration

lnstruction

of Wire

Controller

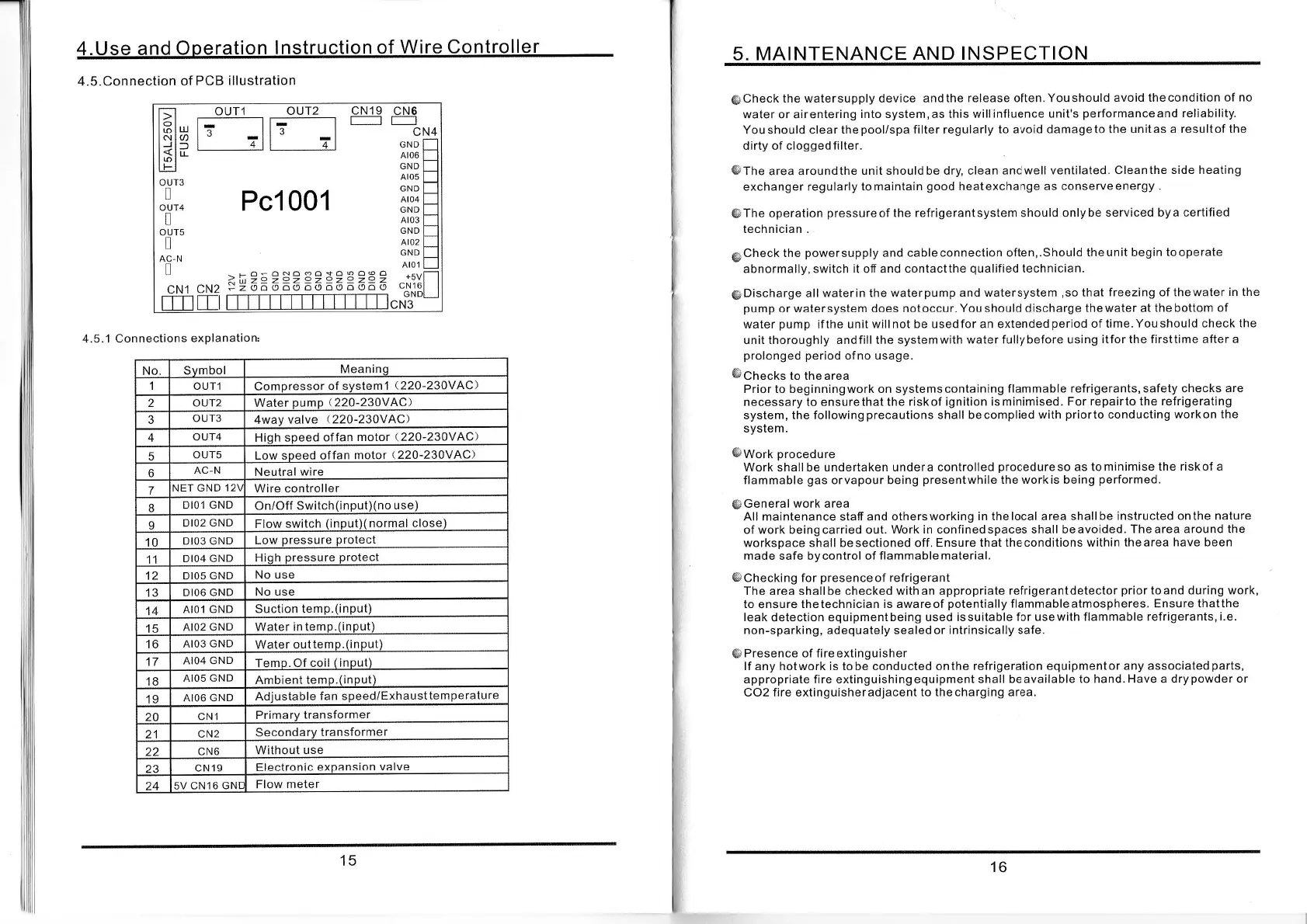

4.5.Connection of

PCB illustration

4.5.1 Connections

explanation:

No.

Svmbol

Meaninq

I OUTl

Compressor

of system

1

(220-230VAC)

2

OUT2

Water

pump

(220-230VAC)

3

OUT3

4wayvalve

(220-230VAC)

4

OUT4

Hiqh speed

offan motor

(220-230VAC)

5

OUT5

Low speed

offan motor

(220-23OVAC)

6

AC-N

Neutral

wire

7

\ET GND 12

Wire controller

DIOl

GND

On/Off Switch(input)(no

use)

o DIO2

GND

Flow switch

(input)(

normal

close)

10

DIO3 GND

Low

pressure

protect

11

DI04 GND

Hiqh

pressure

protect

12 DI05

GND

No use

13

DIO6

GND No use

14

AIOl GND

Suction temp.(input)

15

AI02 GND Water in temp.(input)

16

AI03

GND

Water outtemp.(input)

17

AIO4 GND

Temp.

Of coil

(input)

18

AIO5 GND

Ambient

temp.(input)

10

A106 GND

Adjustable

fan

speed/Exhausttemperature

cN1

Primarv

transformer

21

CN2

Secondary

transformer

22

cN6

Without

use

l3

CN1 9

Electronic

expansion

valve

24

5VCN16GNt

Flow

meter

15

16

5. MAINTENANCE

AND INSPECTION

66Check

the

watersupply device andthe

release often.Youshould

avoid thecondition of

no

water or airentering

into system,as this

willinfluence unit's

performanceand

reliability.

Youshould clear

thepool/spa filter regularly

to

avoid

damageto the unitas

a resultof the

dirty of clogged

filter.

&The

area aroundthe

unit shouldbe dry, clean andwell

ventilated, Cleanthe

side heating

exchanger regularly tomaintain

good

heatexchange as conserveenergy

.

&The

operation

pressureof

the refrigerantsysiem

should onlybe

serviced bya certified

technician.

6pCheck

the

powersupply

and cableconnection often,.Should theunit

begin tooperate

abnormally, switch lt of and contactthe

qualified

technician.

6Discharge

all waterin the waterpump and

watersystem

,so

that

freezing of thewater in the

pump

or watersystem

does notoccur. Youshould

discharge thewaier at thebottom of

water

pump

ifthe unit willnot

be usedfor an extendedperiod

of time.Youshould

check the

unitthoroughly andfill thesystemwithwaterfullybeforeusingitforthefirsttimeaftera

prolonged period

ofno

usage.

@Checks

to thearea

Prior

to

beginningwork on systemscontaining

flammable refrigerants, safety checks are

necessary

to

ensurethat the riskof ignition

isminimised. For repairto the

refrigerating

system, the followingprecautions

shall becomplied with

priorto

conducting workon

the

system.

&Work procedure

Work

shallbe undertaken

undera controlled

procedureso

as tominimise the

riskof a

flammable

gas

orvapour being

presentwhile

the workis being

performed.

@

General work area

All maintenance staff and othersworking

in thelocal area shallbe

instructed onthe nature

of work beingcarried out. Work

in

confinedspaces

shall beavoided.

Thearea around the

workspace shall besectioned off. Ensure that theconditions

within thearea

have been

made safe bycontrol of

flammablematerial.

@Checking for

presenceof

refrigerant

The

area

shallbe checked withan appropriate

refrigerantdetector

prior

toand during

work,

to ensure thetechnician

is aware of

potentially

flammable

atmospheres. Ensure thatthe

leak

detection equipmentbeing

used issuitable for usewith

flammable refrigerants, i.e.

non-sparking, adequately sealed or intrinsically safe.

6

Presence of fire extinguisher

lf any hotwork is tobe conducted onthe refrigeratlon

equipmentor any associatedparts,

appropriate fire extinguishingequipment shall

beavailable to hand. Have a drypowder

or

C02 fire extinguisheradjacent to thecharging

area.

, o.oNo40<o6o@o

litt2o2aza2oza

2oZ

.' z o o o o o o o o o

o

o

ö

o

Loading...

Loading...