This document is a service manual for the Baby Lock BLE8 sewing machine, an overlock machine designed for various sewing tasks. The manual provides detailed instructions for adjustment, maintenance, and troubleshooting, ensuring optimal performance and longevity of the device.

Function Description:

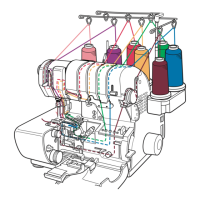

The Baby Lock BLE8 is an advanced overlock sewing machine, also known as a serger, designed to create professional-quality seams, finish raw edges, and perform decorative stitching. It is capable of handling a variety of fabrics, from delicate silks to heavy denim, making it a versatile tool for both home sewers and professionals. The machine utilizes multiple threads (typically 3 or 4) to form secure and stretchable stitches, which are essential for knit fabrics and garments requiring flexibility.

Key functions include:

- Overlock Stitching: Creates strong, durable seams while simultaneously trimming and encasing the fabric edge, preventing fraying.

- Chain Stitching: Forms a flexible stitch that can be used for construction or decorative purposes.

- Rolled Hemming: Produces a fine, decorative edge finish, often used on lightweight fabrics.

- Flatlocking: Creates a flat, decorative seam that lies flush with the fabric surface.

- Differential Feed: Allows for precise control over fabric feeding, preventing stretching or puckering on various fabric types. This feature is particularly useful when working with stretchy knits or delicate materials.

The machine's design incorporates a sophisticated threading system, including needle, upper looper, and lower looper threads, which work in conjunction with a chain looper to form complex stitch patterns. The ability to adjust various components, such as needle guards, chain looper thread take-up, and chain needle tension, ensures that the machine can be fine-tuned for specific sewing projects and thread types.

Important Technical Specifications:

While the manual does not explicitly list all technical specifications like motor power or maximum stitch speed, it provides critical adjustment values and component details that define its operational parameters:

- Needle System: ELX705CF 90/14. This specifies the type and size of needle recommended for optimal performance.

- Fabric Type: Cotton 1-layer, 100% polyester spun thread (maxi-lock or metrosene thread). This indicates the machine's compatibility with common sewing materials and threads.

- Needle (right): 3-thread sewing. This refers to the configuration for specific stitch types.

- Stitch Length: 3.0mm (max). This sets the maximum length of individual stitches.

- Tension Force: N (Newtons). While the exact value isn't given, the manual refers to tension adjustments.

- Stitch Selector: B. This likely refers to a specific setting or mode for stitch selection.

Key Adjustment Values (from "Adjusting gauge" and "Adjustment of Needle, Lower looper, Upper looper, Chain looper & Presser foot" sections):

- Height of presser foot: 4.6 mm.

- Distance of chain looper tip from right side of overlock right needle (O2): 2.0 mm.

- Distance of chain looper tip from center of chain looper shaft: 72.8 mm.

- Distance of lower looper tip from center of lower looper shaft: 55.4 mm.

- Distance of lower looper tip from right side of overlock right needle (O2): 8.6 mm.

- Height of overlock right needle (O2): 10.1 mm.

- Height of feed dog: 4.9 - 0.1 mm.

- Height of needle (ELX705CF 90/14): 10.1 +0.05 -0 mm.

- Upper looper adjustment: 0.8 ±0.3 mm.

- Adjustment of lower looper and upper looper (Max.): 8.5 mm.

- Needle guard adjustment (Overlock Needle): 0.2-0.3 mm clearance between the front & back needle guard and the needle.

- Needle guard adjustment (Chain Needle): 0 mm clearance between the overlock back needle guard and the needle.

- Chain looper front needle guard adjustment: 0.2 - 0.3mm clearance between the chain looper front needle guard and the C3 needle.

- Chain looper thread take-up adjustment: 16.0 ±0.5 mm (height of C1 needle on the way of returning of the chain looper).

- Chain needle tension unit adjustment: 55 ±5g (tension force).

- Thread delivery system clearance: 0.9mm (rear) and 0.4mm (front) between the thread press driving arm and thread press shaft.

Usage Features:

The Baby Lock BLE8 is designed for user-friendly operation, with clear instructions for threading, stitch selection, and basic adjustments. The manual emphasizes the importance of correct settings for optimal stitch quality.

- Versatile Stitching Options: The machine supports various stitch types, allowing users to achieve different finishes for diverse projects.

- Adjustable Components: Users can adjust the presser foot height, needle position, and looper settings to accommodate different fabric thicknesses and desired stitch effects.

- Thread Delivery System: The machine features a sophisticated thread delivery system with multiple tension units, ensuring consistent thread flow and balanced stitches.

- Sensor Cables: The inclusion of needle thread and looper thread sensor cables indicates advanced features for monitoring thread status, potentially preventing issues like thread breakage or skipped stitches. These sensors likely contribute to the machine's ability to maintain consistent stitch quality.

- Fine-Tuning Screws: Dedicated fine-tuning screws for needle and looper thread sensor cables allow for precise adjustments to optimize thread tension and delivery.

Maintenance Features:

The service manual is primarily focused on maintenance, providing detailed, step-by-step instructions for adjustments, replacements, and troubleshooting. This ensures that the machine can be kept in optimal working condition.

- Needle Guard Adjustment: Comprehensive instructions are provided for adjusting both overlock and chain needle guards to maintain proper clearance and prevent needle breakage.

- Chain Looper Thread Take-Up Adjustment: Detailed steps for timing adjustment and thread take-up height adjustment are included to ensure smooth thread flow and correct stitch formation.

- Chain Needle Tension Unit Adjustment: Instructions for adjusting the tension knob and replacing the seal are provided to maintain consistent chain needle tension.

- Thread Delivery System Adjustment: This section covers adjusting the rear and front clearance of the thread delivery system, crucial for preventing thread tangles and ensuring smooth operation.

- Replacement of Timing Belt of Thread Delivery Unit: Step-by-step guide for disassembling and reassembling the thread delivery unit, including instructions for adjusting timing and checking stitches.

- Replacement of Springs of Thread Delivery Unit: Instructions for replacing various springs (stitch connecting arm plate, looper thread pulling plate, thread pulling movable spring, and disc press spring) to restore proper tension and movement.

- Replacement of Sensor Cable: Detailed procedures for replacing fabric thickness, needle thread, and looper thread sensor cables, including instructions for moving stitch joint arm plates and checking stitches.

- Adjustment of Stitches: Comprehensive guidance on adjusting needle and looper thread sensor cables to achieve balanced stitches and prevent puckering. This involves turning adjusting screws clockwise to loosen and counter-clockwise to tighten.

- Checking Threading Steel Pipe Joint: Instructions for verifying the proper connection of the threading steel pipe joint, which is vital for the machine's lubrication or air delivery system (in the case of an air-threading serger).

- Checking Pump and Replacement of Piston Cap: Procedures for checking pump deflation and replacing the piston cap, indicating the presence of a pump system, possibly for air-threading or lubrication.

- Troubleshooting: A dedicated section for common issues like unbalance in needle and looper threads, thread breaks, and air deflation from the pump, directing users to relevant sections for solutions.

The manual emphasizes the importance of precise adjustments and proper component replacement to maintain the machine's high performance and extend its lifespan. The detailed diagrams and clear instructions make it an invaluable resource for technicians and advanced users.