Do you have a question about the Bartec HYGROPHIL H 4230-10 A Series and is the answer not in the manual?

| Measuring range humidity | 0 ... 100 % RH |

|---|---|

| Output signal | 4 ... 20 mA, 2-wire |

| Protection class | IP65 |

| Housing Material | Stainless Steel |

| Accuracy temperature | ±0.2°C |

| Storage Temperature | -40...85 °C |

| Accuracy humidity | ±2 %RH (at 23 °C, 20...80 %RH) |

Defines the purpose and application areas of the HYGROPHIL® H 4230 measuring system.

Explains the psychrometric gas humidity measurement principle used by the HYGROPHIL® H 4230.

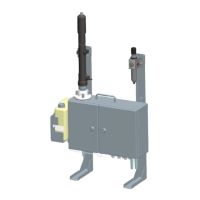

Describes the physical layout of the HYGROPHIL® H 4230 system components.

Details the components and function of the measuring chamber and its internal systems.

Details how signals are processed and equipment functions are monitored by the electronics.

Describes the two analogue current outputs and the field bus interface (PROFIBUS DP).

Specifies the basic configuration of the HYGROPHIL H Type 4230-10.

Lists various accessories available for the HYGROPHIL H 4230.

Lists available spare parts for the HYGROPHIL H 4230 system.

Details specific components for the measuring chamber.

Lists consumables required for operation, such as tenside.

Provides general safety guidelines for operating and maintaining the HYGROPHIL unit.

Outlines safety instructions specific to the HYGROPHIL H 4230 equipment.

Specifies requirements for selecting a suitable installation location to ensure safe operation.

Details the safety aspects and procedures for connecting the equipment electrically.

Provides safety instructions related to operating the HYGROPHIL H 4230.

Outlines safety requirements for operating the device in explosion-protected areas.

Explains the procedure for mounting the HYGROPHIL H 4230 unit onto a wall.

Describes how to set up the HYGROPHIL H 4230 for mobile operation using a stand holder.

Provides guidance on connecting the HYGROPHIL H 4230 to various systems and power.

Provides instructions and guidelines for correctly mounting the gas sampling hose.

Explains the requirements and procedure for connecting compressed air to the unit.

Provides instructions on how to fill the water storage tank with demineralised water and surfactant.

Provides instructions for installing the unit within a specific explosion-protected enclosure.

Lists the prerequisite conditions for safely starting up the HYGROPHIL H 4230.

Explains the initial operating mode, self-test, and start-up phase of the equipment.

Introduces the concept of configuring the device settings via programming.

Provides steps for changing the PROFIBUS slave address of the HYGROPHIL H 4230.

Provides general information and interaction guidelines for programming the HYGROPHIL H 4230.

Details the step-by-step process for entering and navigating programming mode.

Explains how to change various program parameters for the HYGROPHIL H 4230.

Guides on assigning measurement variables and setting current ranges for analogue outputs.

Explains how to set and adjust the gas sampling hose heating parameters.

Covers configuration settings for temperature sensors, safety switch-off, water detectors, etc.

Explains how to define limits for measured values and activate warning relays.

Provides general maintenance guidelines and periodic checks for the HYGROPHIL H 4230.

Explains how to test the analogue outputs using a mA-meter in test mode.

Covers maintenance aspects of the measuring chamber, including cleaning intervals and types of dirt.

Provides step-by-step instructions for safely disassembling the measuring chamber.

Guides on how to detach, replace, and reconnect the humid temperature sensor.

Explains the procedure for changing the dry temperature sensor without disassembling the chamber.

Details the cleaning process for different parts of the measuring chamber.

Provides instructions for reassembling the measuring chamber after cleaning or part replacement.

Describes how to calibrate the internal water detector if it stops responding.

Explains how to change the peristaltic hose pump for the water system.

Outlines maintenance tasks for the compressed air conditioner.

Explains the procedure for replacing fuses located in the electronics enclosure.

Provides instructions for replacing the display and PROFIBUS board.

Details the steps for replacing the main electronics board of the unit.

Guides on how to replace the proportional valve component.

Explains procedures for reference and zero point control according to EN15267-3.

Details the structure of PROFIBUS data frames, including command codes and data addresses.

Explains how to activate and deactivate standby mode for the HYGROPHIL H 4230.

Describes the different communication channels available via PROFIBUS.

Lists the measured values available through the PROFIBUS interface and their data formats.

Describes arithmetic values like dew point, relative humidity, and enthalpy available via PROFIBUS.

Details output control status, setpoints, and configuration for analogue outputs.

Explains parameters related to hose heating, error time, and HT compensation.

Covers parameters for proportional valve control, pump control, and limit monitoring.

Provides example sequences for reading data and changing operating modes via PROFIBUS.

Illustrates how to query the dew point value from the HYGROPHIL H via PROFIBUS.

Shows how to change the operating mode to standby via PROFIBUS.