16

17

CONDITION CAUSE CORRECTIVE

Compressor over heating 1. Undersized unit for air

requirements

2. Compressor location

3. Air leaks in the system

4. Restricted air filter

5. Improper grade or level

of oil

6. Worn, damage, or carbon

build up on valve

7. Carbon build up at after-

cooler tube or check

valve

1. Contact your dealer /

distributor

2. See installation section

3. Fix leaks

4. Clean or replace filter

5. Replace with SAE 30

Weight non-detergent

compressor oil

6. Clean, repair or replace

valves

7. Clean or replace

Pressure switch unloading

valve does not function

or leak air when unit is

operating or not operating

1. Pressure switch

unloading valve may be

dirty or faulty

2. Check valve may be dirty

or faulty

1. Clean, or replace

unloading valve

2. Clean, or replace check

valve

Water in air tank 1. Condensation in the air

tank during normal usage

1. Drain daily or install an

automatic drain

Oil leaks or appearance of

oil on the compressor

1. Spillage of oil when filling

2. Overfilling the crankcase

3. Improper grade of oil

4. Leak at oil filler plug

5. Oil leak at gasket,

cylinder or crankcase

6. Loose plug

7. Loose side or end plate

8. Oil seal leak

1. Wipe unit clean

2. Drain oil and fill to proper

level

3. Replace with proper

SAE 30 non-detergent

compressor oil

4. Tighten or replace oil

filler plug

5. Replace gaskets as

required

6. Tighten plug

7. Tighten plates

8. Replace oil seal

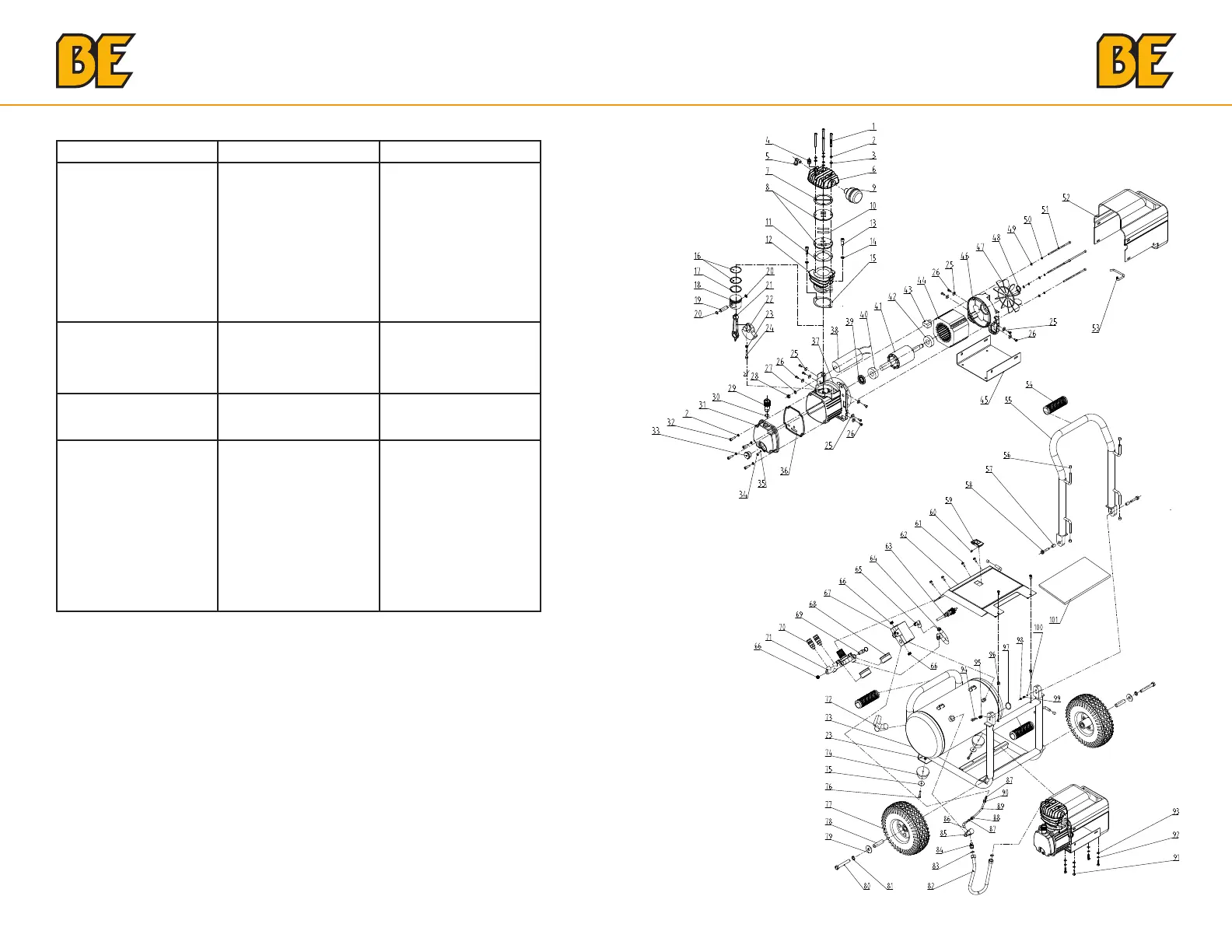

troubleshooting exploded view

Loading...

Loading...