28

CP.SAM CONTROL PANEL

ELECTRICAL CONNECTIONS

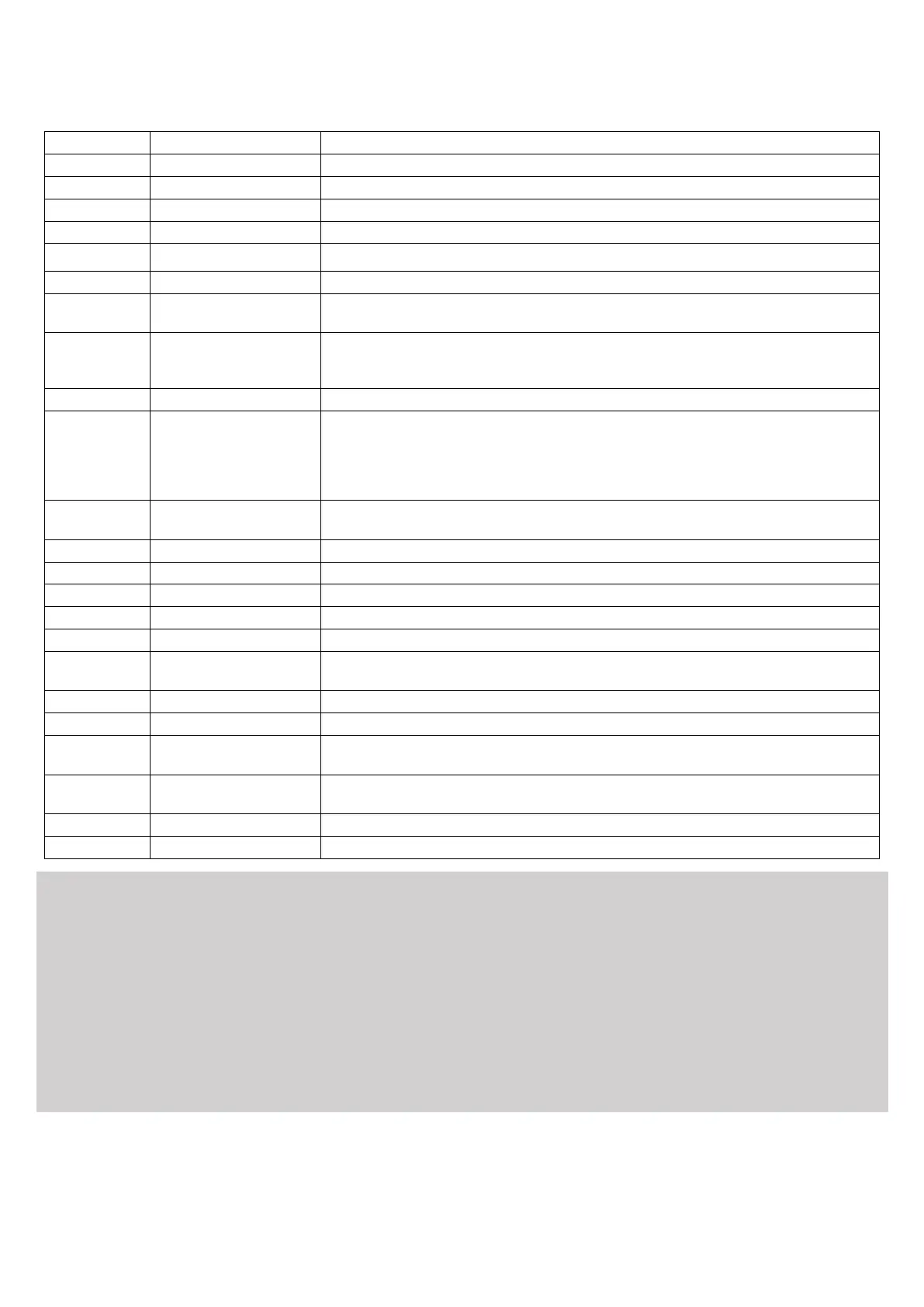

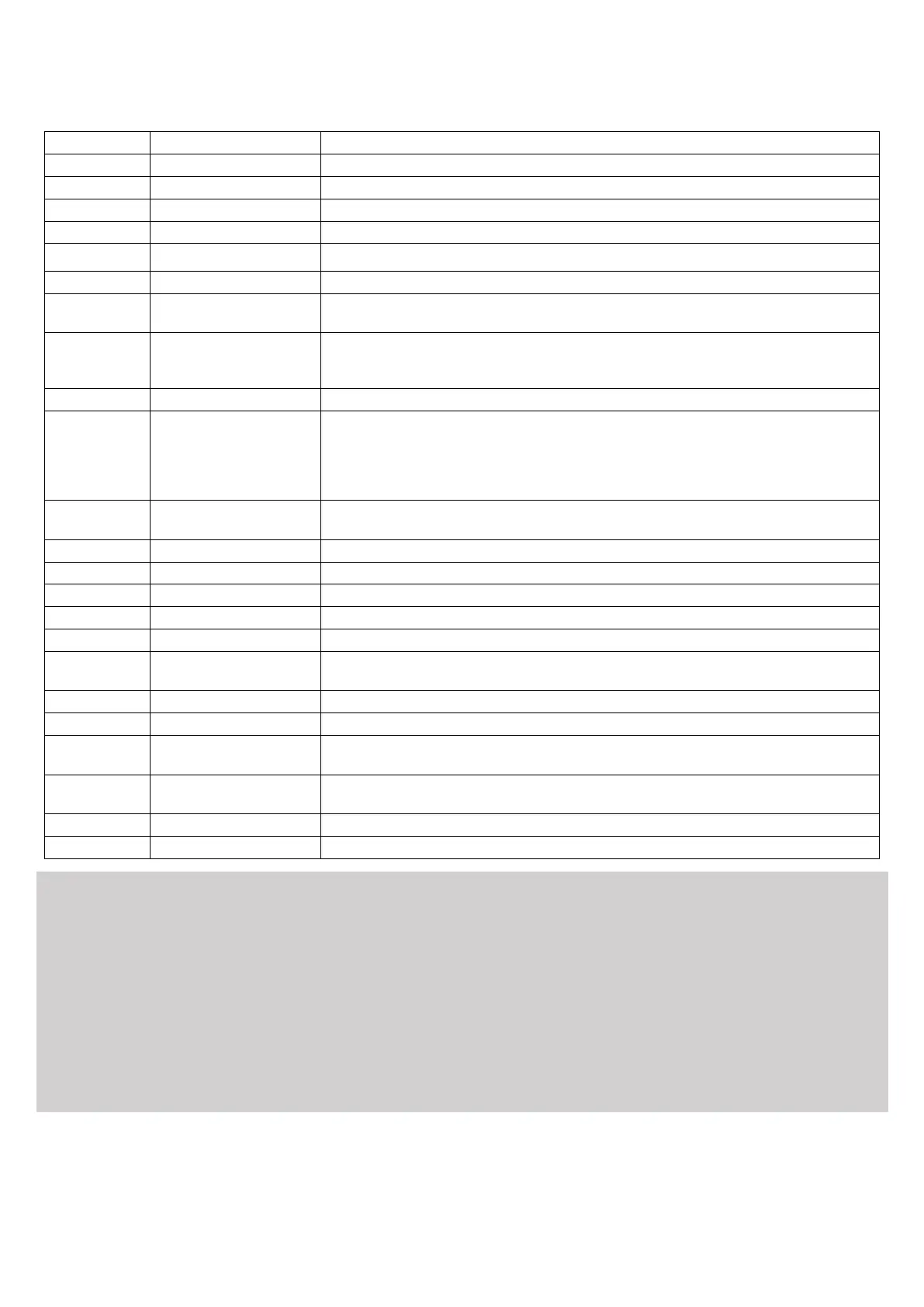

The following table shows the electrical connections in Fig. 12:

Terminals Function Description

L-N-GND Supply Mains input 115-230Vac 50-60Hz

+ BATT - Batteries Input for connection of the back-up batteries (accessory)

M0T1 Motor 1 Quick connector for connection of 24 Vdc MOT1 motor (SAM.E24).

M0T2 Motor 2 Connector for connection of 24 Vdc MOT2 motor (SAM.24).

BLINK Flashing light 24Vdc flashing connection 4W max.

LOCK Electric lock Electric lock connection.

AUX1 AUX 1 auxiliary output

Output with configurable N.O. contact from working parameter AUX1. Max load 500

mA.

+ 24V - Output 24Vdc

Power supply output accessories 24Vdc/0.5A max.

ATTENTION!! With ESA:ON logic, during the Stand-by phase, the power supply of

the accessories is interrupted. See ESA Logic

ENC1 Encoder MOT1 Quick connector for connection of MOT1 encoder (SAM.E24).

BAR Sensitive edge

Sensitive bar contact input, a resistor is pre-installed on the terminals of 8,2 KOhm.

Resistive bar 8K2: connect the bar to the terminals eliminating the pre-installed resis-

tance as indicated in Figure 12.

Mechanical bar: connect the bar in series to the resistance as indicated in Figure 12.

The intervention of the bar stops movement of the gate and inverts for approx. 3s.

ENC2 Encoder MOT2

Connector for connection of the MOT2 encoder (SAM.24).

Use a 3x0.5mm

2

long cable maximum 10m.

PHOT OP Photocell OPEN Photocell input enabled in OPENING and CLOSURE (N.C. contact).

PHOT CL Photocell CLOSE Photocell input enabled in CLOSURE (N.C. contact).

STOP STOP STOP button input (N.C. contact)

OPEN OPENED OPEN button input (N.O. contact). You can connect a timer for opening in time slots.

CLOSE CLOSED CLOSE button input (N.O. contact).

PED PEDESTRIAN

Pedestrian button input (N.O. contact), opening command of motor 1, see TPED pa-

rameter.

P.P. Step-by-Step Step-by-Step button input (N.O. contact) .

COM Common Inputs Common for the inputs for control and photocells and STOP

AUX2 AUX 2 auxiliary output

Output with configurable N.O. contact from working parameter AUX1. Max load 500

mA.

ANT-

SHIELD

Antenna

Integrated radio-receiver board antenna connection

(FRONT: Signal - SHIELD: Screen)

EXP1 Extension 1 Expansion connector for serial KNX or pro.UP

EXP2 Extension 2 Expansion connector for serial pro.UP

CONNECTIONS CHECK

1) Disconnect power supply.

2) Manually release the gates, bring them to approx. half the stroke and lock them again.

3) Restore the power supply.

4) Give a step by step command using the button connected to the input of the PP, remote control or button <->.

5) The gates must move in opening.

If this is not the case, simply invert the motor running wires, rotating the connector of MOT1 on SAM.E24 180° degrees and

inverting the MOT2 wires for the SAM.24 motor.

6) Using MINV logic, select the motor which must start to move first in opening, see Fig.14.

7) Execute an autoreset procedure (see AUTOSET menu).

The default setting includes installation of the motor with the control panel (SAM.E24) on the right gate (as in the Fig.13) with the

right gate that starts first (MINV:OFF logic)

Loading...

Loading...