CIAO e

5

Use the power cable supplied to connect the boiler to the

mains power supply.

If the power cable is replaced, use a cable type HAR H05V2V2-

F, 3 x 0.75 mm2, with max. outside diameter 7 mm.

3.4 Gas connection

Before connecting the appliance to the gas network, check that:

- national and local regulations are complied

- thegastypeistheonesuitablefortheappliance

- the piping is clean.

The gas pipe must be installed outdoor. If the pipe goes through the

wall, it must go through the central opening, in the lower part of the

template.Itisadvisabletoinstallalterofsuitabledimensionson

the gas line if the distribution network had solid particles.

Once the appliance has been installed check that connections are

sealed according to current installation regulations.

3.5 Fumes exhaustion and air suction (CIAO C.S.I. e)

For fumes exhaustion, refer to the current local and national regu-

lations.AlwayscomplywithlocalstandardsoftheFireDepartment,

theGasCompanyandwithpossiblemunicipaldispositions.

Thereleaseofcombustionproductsisassuredbyacentrifugalfan

placed inside the combustion chamber and its correct operation

isconstantlycheckedbyapressureswitch.Theboilerissupplied

withouttheuegasoutlet/airsuctionkit,sinceitispossibletouse

the accessories for appliance with a forced draught sealed cham-

ber that better adapts to the installation characteristics.

It is essential for ue gas release and the restoration of boiler

combustion air to usecertiedpipes and that connection is car-

riedoutcorrectlyasindicatedbytheinstructionssuppliedwiththe

uegasaccessories.Withonlyonesmokepipeyoucanconnect

morepiecesofapplianceprovidedthateverypieceofapplianceis

sealedchambertype.

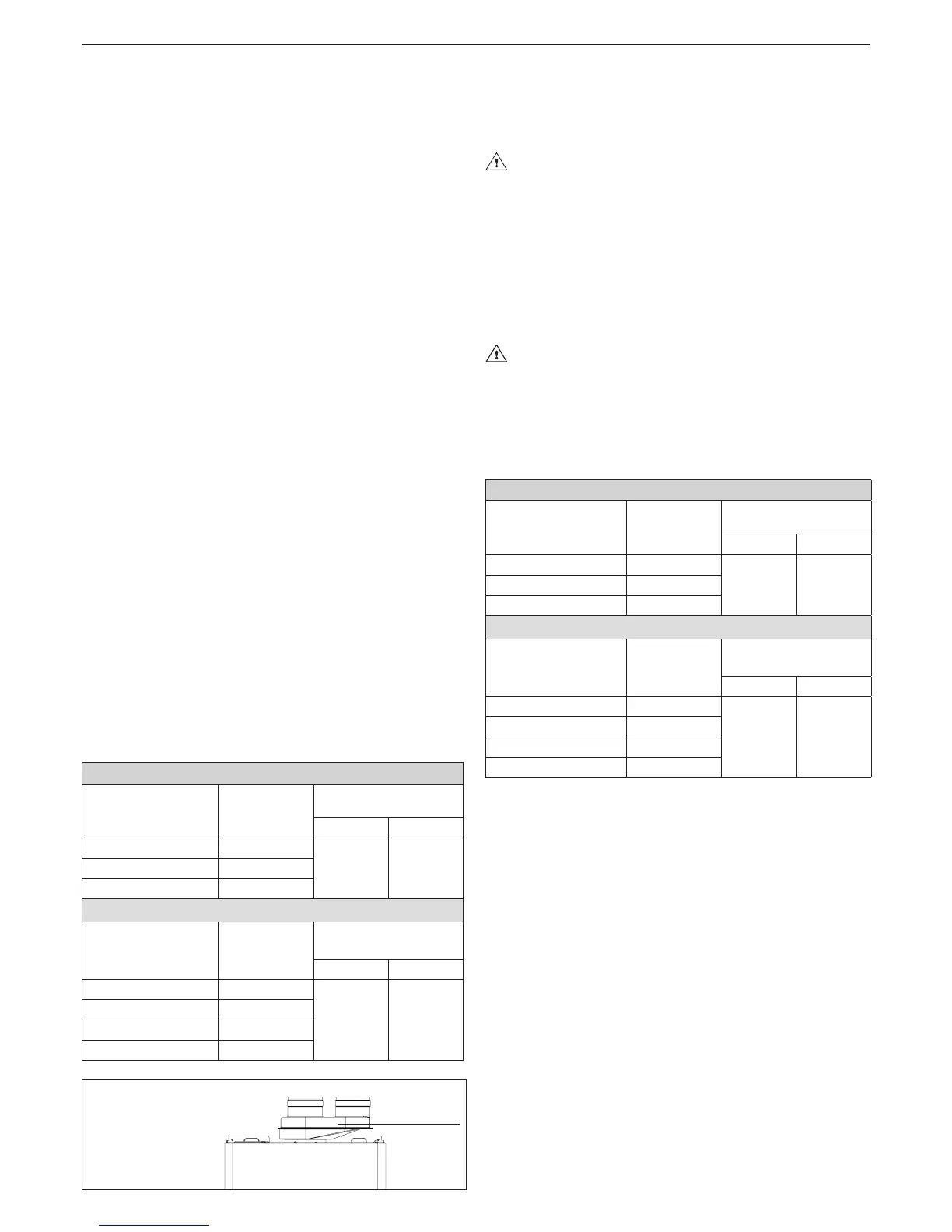

CONCENTRIC OUTLETS (ø 60-100)

The boiler has been designed to be connected to concentric outlet/

suctionpipesandwiththeopeningforairsuction(E)closed(g.

10).Theconcentricoutletscanbeplacesinthemostsuitabledi-

rectionaccordingtoroomrequirements,complyingwiththemaxi-

mum lengths indicated in the table. For installation, follow the in-

structions supplied with the kit. According to the length of the pipes

used,itisnecessarytoinsertaange,selectingonefromthose

containedintheboiler(seethefollowingtable).Whennecessary,

theuegasange(F)mustberemovedusingascrewdriverasa

lever. The table indicates the permitted linear lengths. According to

thelengthofthepipesused,itisnecessarytoinsertaange,select-

ingonefromthosecontainedintheboiler(seethefollowingtable).

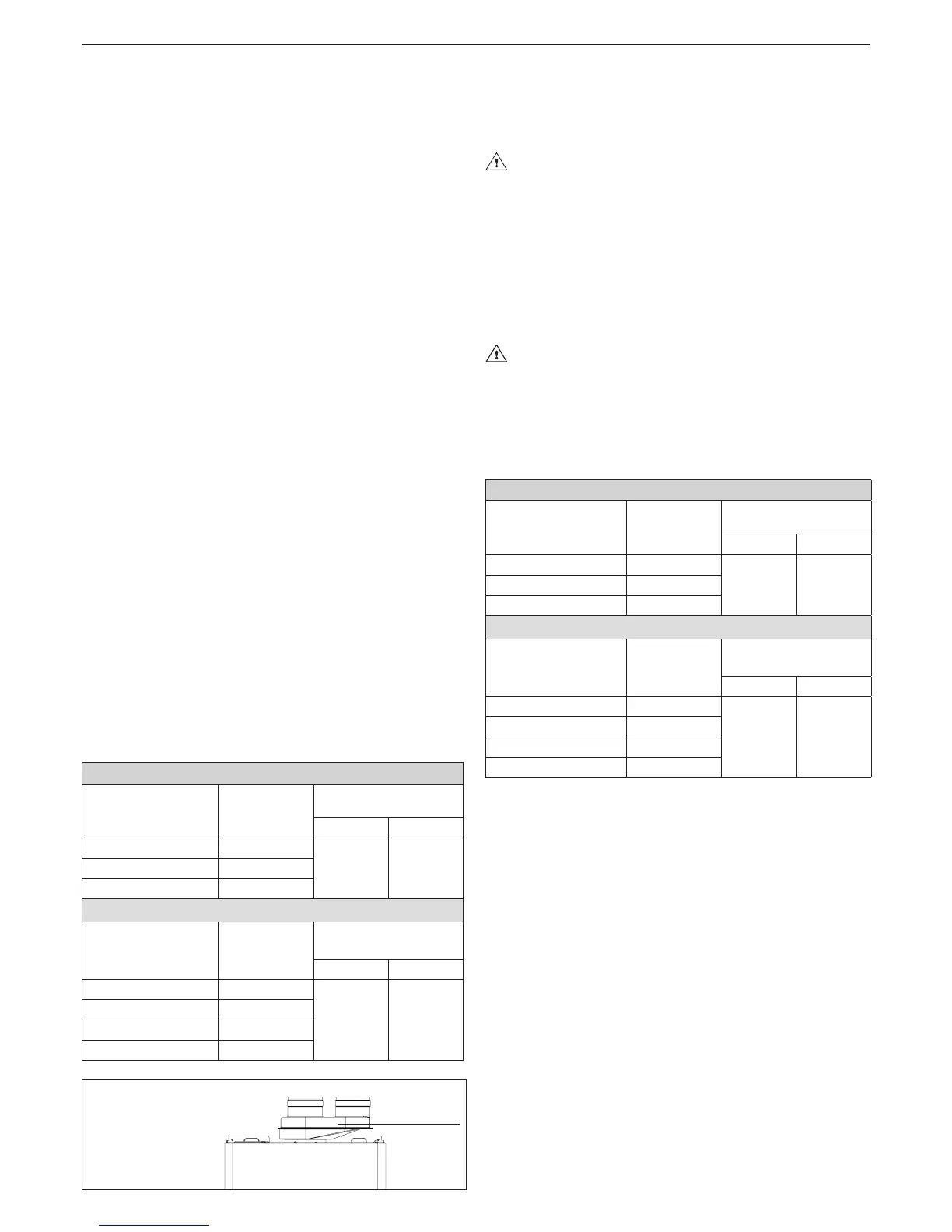

24 C.S.I.

Pipe length

ø 60-100 [m]

Flue gas

ange (F)

Load losses for each

bend (m)

45° 90°

upto0,85

Ø 42

1 1,5

from0,85to2,35 Ø44(**)

from 2,35 to 4,25 not installed

28 C.S.I.

Pipe length

ø 60-100 [m]

Flue gas

ange (F)

Load losses for each

bend (m)

45° 90°

upto0,85 Ø 43

1 1,5

from0,85to1,7 Ø45(**)

from 1,7 to 2,7 Ø 47

from 2,7 to 3,4 not installed

(**)ttedinboiler

air/uegas

splitter

To direct the outlets in the most suit-

ableinstallationway(rightairinput)

there is an air/flue gas splitter kit

available.

TWIN OUTLETS (ø 80) (g. 11) (CIAO 24 C.S.I. e)

Twin outlets can be placed in the most suitable direction according

to the room requirements.

Tousethecombustionairsuctionpipe,oneofthetwoinlets(Gand

H)mustbeselected.Removetheclosureplugwhichisxedusing

screws,andusethespecicadaptorrelatingtotheinletselected.

Theairinletadaptorø80(X)mustbecorrectlyoriented,itis

thereforenecessarytoxitusingtheappropriatescrews,so

thatthelocatingtabdoesnotinterferewiththecasing:Xair

inletadaptorø80-Yairinletadaptorfromø60toø80.

Whennecessary,theuegasange(F)mustberemovedusing

a screwdriver as a lever. The table indicates the permitted linear

lengths.Accordingtothelengthofthepipesused,itisnecessary

toinsertaange,selectingonefromthosecontainedintheboiler

(seethefollowingtable).

TWIN OUTLETS (ø 80) (g. 11) (CIAO 28 C.S.I. e)

Twin outlets can be placed in the most suitable direction according

to the room requirements.

Theairinletadaptormustbecorrectlyoriented,itistherefore

necessarytoxitusingtheappropriatescrews,sothatthe

locating tab does not interfere with the casing.

Whennecessary,theuegasange(F)mustberemovedusing

a screwdriver as a lever. The table indicates the permitted linear

lengths.Accordingtothelengthofthepipesused,itisnecessary

toinsertaange,selectingonefromthosecontainedintheboiler

(seethefollowingtable).

24 C.S.I.

Pipe length

ø 80 [m]

Flue gas

ange (F)

Load losses for each

bend (m)

45° 90°

up to 2+2

Ø 42

1,2 1,7

from 2+2 to 6+6 Ø44(**)

from 6+6 to 16+16 not installed

28 C.S.I.

Pipe length

ø 80 [m]

Flue gas

ange (F)

Load losses for each

bend (m)

45° 90°

up to 3+3 Ø 43

1,2 1,7

from 3+3 to 7+7 Ø45(**)

from 7+7 to 11+11 Ø 47

from 11+11 to 14+14 not installed

(**)ttedinboiler

Loading...

Loading...