13

ENGLISH

28 C.S.I.

32 C.S.I.

36 C.S.I.

12 R.S.I.

15 R.S.I.

25 R.S.I.

35 R.S.I.

rpm

rpm

rpm

rpm

rpm

rpm

rpm

Natural gas

(G20)

44

45

52

51

42

55

60

LPG

propane (G31)

43

45

52

51

41

54

60

Maximum heating fan rpm

Gas valve calibration

• Power the boiler.

• Open the gas tap.

• Turn the function selector to OFF/RESET (digit “--”).

• Pull off the domestic hot water temperature selector knob (7, Fig. 12.1)

and the domestic hot water function selector knob (6, Fig. 12.1).

• Press the combustion analysis button CO.

• Wait for the burner to ignite. “CO” is displayed on the digital display and

the boiler works at maximum heating power. The flue cleaner function

remains active for a maximum of 15 min; if a delivery temperature of 95°C

is reached, the burner switches off. It is re-ignited when this temperature

falls below 75°C.

• Remove the plug and insert the fumes analysis probe.

• Turn the max. heating trimmer clockwise until it reaches the maximum fan

rpm (see table).

28 C.S.I.

32 C.S.I.

36 C.S.I.

12 R.S.I.

15 R.S.I.

25 R.S.I.

35 R.S.I.

%

%

%

%

%

%

%

Natural gas

(G20)

9,0

9,0

9,0

9,0

9,0

9,0

9,0

LPG

propane (G31)

10,0

10,0

10,0

10,0

10,0

10,0

10,0

CO2 max

• Check the CO

2 value: if the value does not match that indicated in the

table, turn the maximum gas valve adjustment screw.

• Turn the max. heating trimmer anti-clockwise until it reaches the minimum

fan rpm (see table).

28 C.S.I.

32 C.S.I.

36 C.S.I.

12 R.S.I.

15 R.S.I.

25 R.S.I.

35 R.S.I.

%

%

%

%

%

%

%

Natural gas

(G20)

9,0

9,0

9,0

9,0

9,0

9,0

9,0

LPG

propane (G31)

10,0

10,0

10,0

10,0

10,0

10,0

10,0

CO2 min

• Check the CO

2 value: if the value does not match that indicated in the

table, turn the minimum gas valve adjustment screw.

• Turn the max. heating trimmer to the maximum heating fan rpm (see table)

• To exit the flue cleaner function, turn the control knob 6

• Remove the fumes analysis probe and put back the plug.

Remount the knobs on the panel. The “combustion analysis” function

automatically deactivates if the board generates an alarm.

If a fault develops during the combustion analysis phase, perform the release

procedure as follows:

Turn the function selector 6 to

, then to , and then move it to the

required function.

15 - GAS CONVERSION

It is easy to convert from one gas family to another even after the boiler has

been installed.

This operation must be performed by professionally qualified staff.

The boiler is designed to work with natural gas (G20), as indicated on the

product plate.

The boiler can be converted to propane using the relative kit supplied as an

accessory.

To disassemble, proceed as follows (Fig. 15.1):

• disconnect the boiler from the power supply and close the gas tap

• remove the shell and cover of the air distribution box

• release the panel and turn it forwards

• remove the gas pipe (D)

• remove the nozzle (E) contained in the gas train and replace it with the

one contained in the kit

• remount the gas train (check that the gas pipe connected to the fan mixer

is in position)

• put back the air distribution box cover

• power the boiler and open the gas tap.

Adjust the boiler as described in the “Adjustments” section, referring to LPG

data.

The boiler may only be converted by qualified staff.

After conversion, apply the new identification plate contained in the kit.

16 - CHECKING COMBUSTION PARAMETERS

To analyse combustion, proceed as follows:

• turn the function selector to OFF/RESET (digit “--”)

• pull out the central knob (6, Fig. 12.1) on the panel

• press the combustion analysis button (CO, Fig. 13.2)

• insert the analyser probes in the relative positions on the air distribution

box, after removing the screw F and the plug G (Fig. 15.2)

• check that the values of CO

2 correspond to those indicated in the table.

If the value displayed is different, modify it as indicated in the “Gas valve

calibration” section

• check combustion.

Then:

• remove the analyser probes and close the combustion analysis taps with

the relative screw cap

• put back the central knob 6 on the panel.

The fumes analysis probe must be fully inserted.

IMPORTANT

The function that switches off the boiler when water temperature reaches

a maximum of about 95°C is still enabled during the combustion analysis

phase.

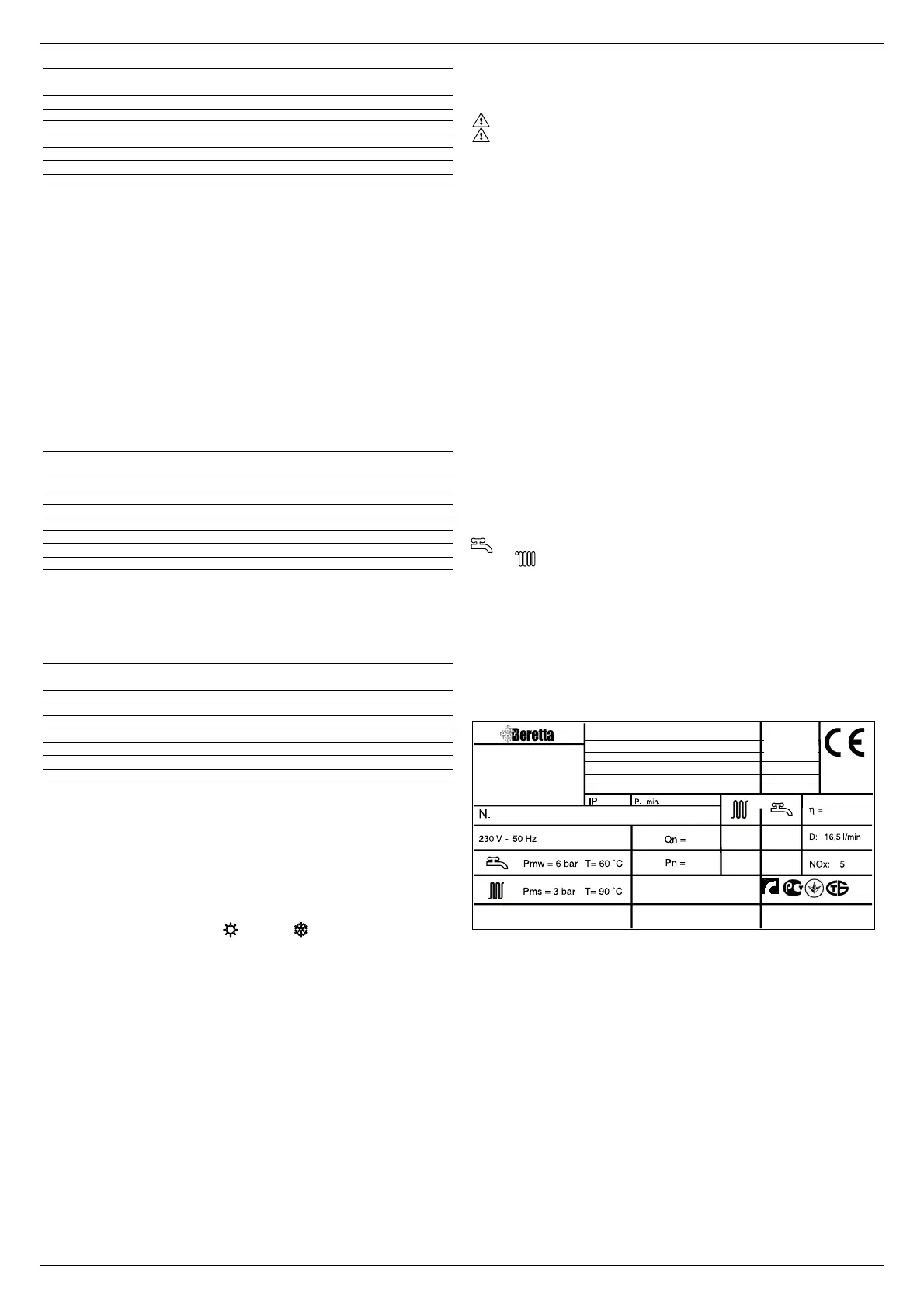

17 - SERIAL NUMBER PLATE

DHW operation

CH operation

Qn nominal capacity

Pn nominal power

IP protection level

P. min minimum pressure

Pmw DHW maximum pressure

Pms CH maximum pressure

T temperature

η working efficiency

D specific capacity

NOx NOx value class

Condensing boiler

Gas type

Gas

category

Loading...

Loading...