Mynute Green E C.S.I.

7

Twin pipes (Ø 80 mm) (Fig. 15)

The twin pipes can face in the direction most suitable for installation

requirements.

For installation, follow the instructions supplied with the specific ac-

cessory kit for condensation boilers.

Arrange the flue gas discharge pipe so it slopes by 3° towards

the boiler.

The boiler automatically adapts the purging to the type of in-

stallation and the length of the pipes. Do not obstruct or choke

the pipes in any way.

For the maximum length indications of the individual pipe see

the graphics (fig. 16).

The use of longer pipes reduces the boiler output.

Maximum straight length

of twin pipe Ø 80 mm

Pressure loss

45° curve 90° curve

25 C.S.I. 53+53 m

1 m 1.5 m

30 C.S.I. 42+42 m

Ø 80 twin pipes with Ø 50 and 60 pipework (Fig. 17)

The characteristics of the boiler allow the Ø 80 flue gas discharge

pipe to be connected to the Ø 50 or 60 range of pipework.

For the pipework we recommend carrying out a design calcula-

tion in order to comply with the applicable prevailing standards.

The allowed base configurations are indicated in the table.

Base pipe configuration table (*)

Air suction 1 90° ø 80 curve

4.5 m ø 80 pipe

Flue gas exhaust 1 90° ø 80 curve

4.5 m ø 80 pipe

Reductio

n from ø 80 to ø 50 or ø 80 to ø 60

flue base curve 90° ø 50 or ø 60

for pipework pipe lengths see the table

(*) Use the plastic (PP) flue accessory systems for condensing boil-

ers that can be found on the residential catalogue price list, ø 50 H1

class and ø 60 P1 class

The boilers come from the factory calibrated to:

- 25 C.S.I.: 4,700 r.p.m. and maximum length reachable is 11 m for

the ø 60 pipe and

1 m for the ø 50 pipe

- 30 C.S.I.: 5,600 r.p.m. and maximum length reachable is 14 m for

the ø 60 pipe and

2 m for the ø 50 pipe

If you need to reach greater lengths compensate for the pressure

drop with an increase of the number of fan rotations as shown in the

adjustments table in order to guarantee the rated heat input.

The minimum calibration must not be modified.

If the prevailing value is greater than 200 Pa the law requires the use

of H1 pressure class flue accessories

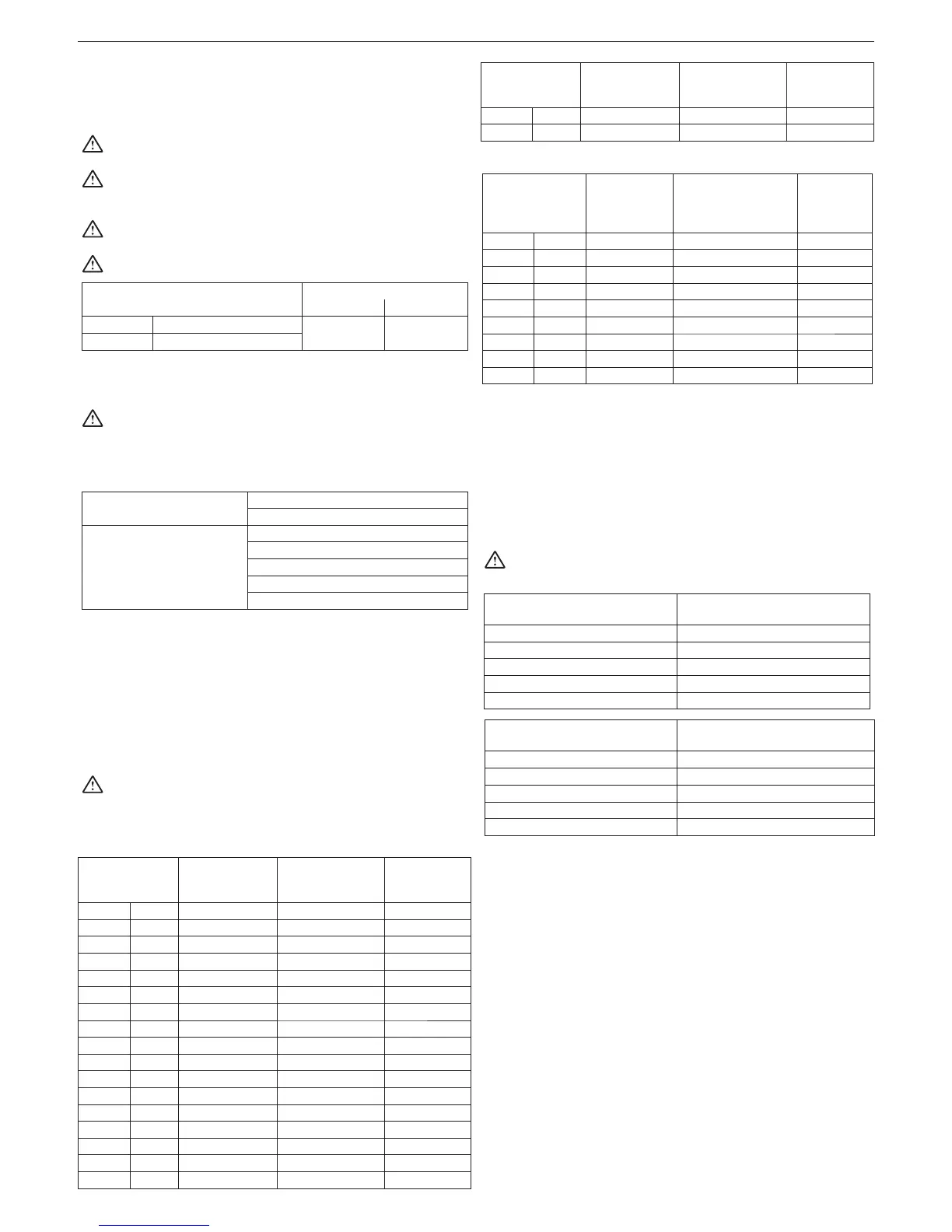

Mynute Green E 25 C.S.I. adjustments table

Maximum number

of fan rotations

(rpm)

Ø 50 pipework pipes

maximum length

Ø 60 pipework pipes

maximum length

ΔP at the boiler

output with

max length (°)

DHW CH

mmPA

4700 3900 1

11 90

4800 4000 4

16 120

4900 4100 6

22 150

5000 4200 8

28 180

5100 4300 10

31 (*) 200

5200 4400 14

- 255

5300 4500 17

- 295

5400 4600 20

- 338

5500 4700 23

- 375

5600 4800 26

- 410

5700 4900 28

- 445

5800 5000 32

- 485

5900 5100 35

- 535

6000 5200 38

- 575

6100 5300 41

- 613

6200 5400 44

650

Maximum number

of fan rotations

(rpm)

Ø 50 pipework pipes

maximum length

Ø 60 pipework pipes

maximum length

ΔP at the boiler

output with

max length (°)

DHW CH

mmPA

6300 5500 49

710

Mynute Green E 30 C.S.I. adjustments table

Fan rotations

maximum number

of fan rotations

(rpm)

Ø 50 pipework

pipes

Maximum length

Ø 60 pipework pipes

Maximum length

ΔP at the

boiler output

with max

length (°

)

DHW CH

mmPa

5600 4700 2

14 145

5700 4800 4

19 183

5800 4900 5

21 (*) 200

5900 5000 8

- 255

6000 5100 11

- 295

6100 5200 13

- 330

6200 5300 15 377

6300 5400 19 440

(*) Compatible length with P1 class pipes

NOTE

If p

ipes different than those in the Beretta catalogue are used you must

see the ΔP values on the above tables to calculate the maximum length

of the pipes.

The Ø 60 and Ø 50 configurations have experimental, laboratory checked

data.

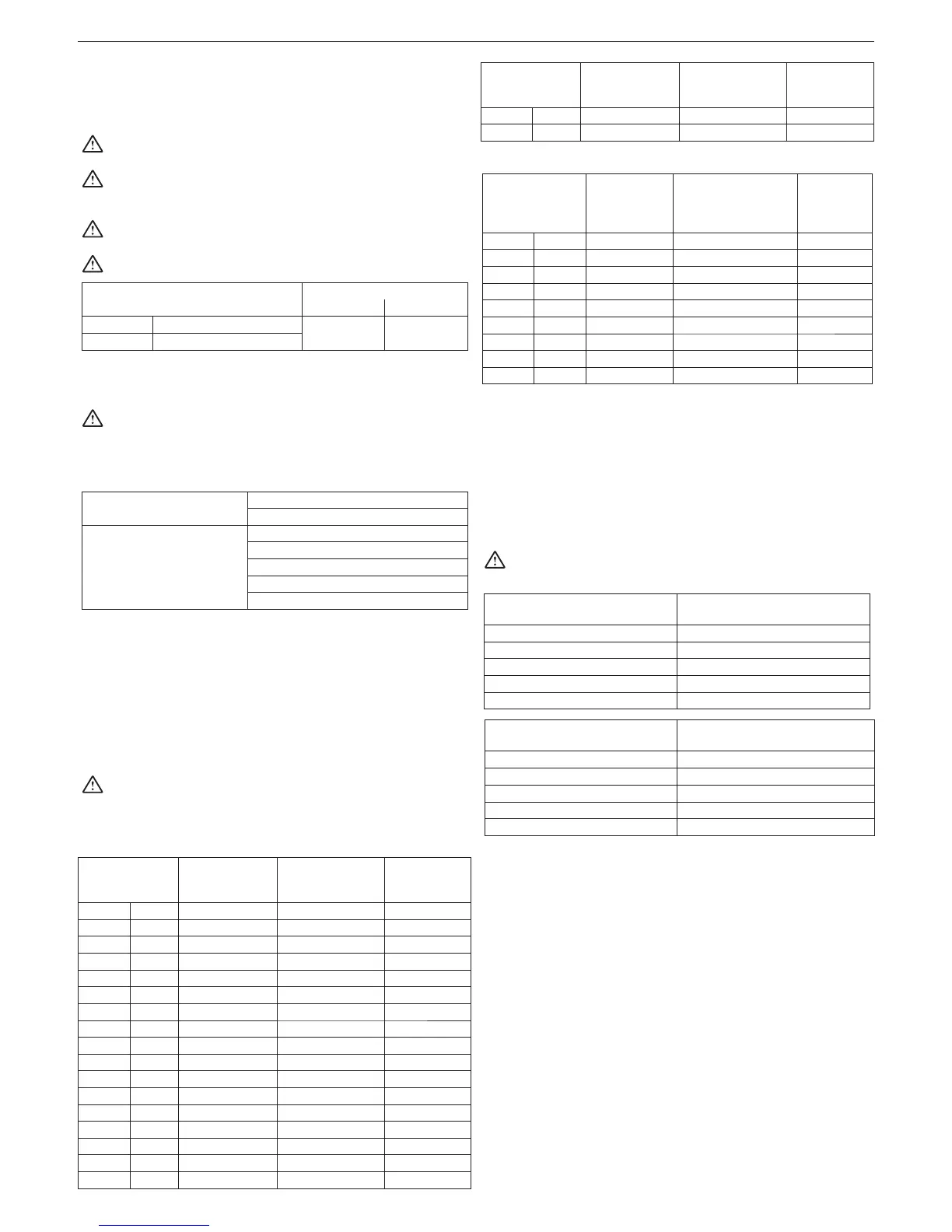

In the event of installations other than those indicated in the “base

configurations” and “adjustments” table, see the equivalent Ø 80 - Ø

60 or Ø 50 linear lengths shown below.

In any case the maximum lengths declared in the booklet are

guaranteed and it is essential that they are not exceeded.

Ø 60 component

Linear equivalent in

metres Ø 80 (m)

45° Ø 60 curve 5

90° Ø 60 curve 8

0.5 m Ø 60 extension 2.5

1.0 m Ø 60 extension 5.5

2.0 m Ø 60 extension 12

Ø 50 COMPONENT Linear equivalent in

metres Ø 80 (m)

45° Ø 50 curve

12,3

90° Ø 50 curve 19,6

0.5 m Ø 50 extension 6,1

1.0 m Ø 50 extension 13,5

2.0 m Ø 560 extension 29,5

3.11 Installation on collective flues in positive pressure

The collective flue is a gas discharge system suitable for collecting

and expelling the combustion products of several appliances in-

stalled on several floors of a building (fig. 18).

The collective flues in positive pressure can be used only for type C

condensing appliances. Consequently the B53P/B23P configuration

is not permitted.

Installation of the boiler on collective flues in pressure is permitted

only at G20 using a specific check valve, supplied as an accessory.

See the related instructions for the assembly procedure.

The boiler is sized to operate correctly up to a maximum internal

pressure of the smoke pipe no higher than the value shown in the

multigas table.

Complete the check valve assembly operations and proceed with

adjustment of the number of fan rotations as shown in the multigas

table.

Ensure that the air suction pipes and combustion product outlet are

airtight.

Installation of the check valve (fig. 19) requires the application of the

ATTENTION label that comes with the same accessory on a visible

part of the boiler shell. Applying the label is essential for safety during

maintenance or replacement of the boiler and/or the collective flue.

Loading...

Loading...