12 | English

1 609 92A 1DD • 23.7.15

tained, the vibration emission may differ. This may

significantly increase the exposure level over the

total working period.

An estimation of the level of exposure to vibration

should also take into account the times when the

tool is switched off or when it is running but not ac-

tually doing the job. This may significantly reduce

the exposure level over the total working period.

Identify additional safety measures to protect the

operator from the effects of vibration such as:

maintain the tool and the accessories, keep the

hands warm, organisation of work patterns.

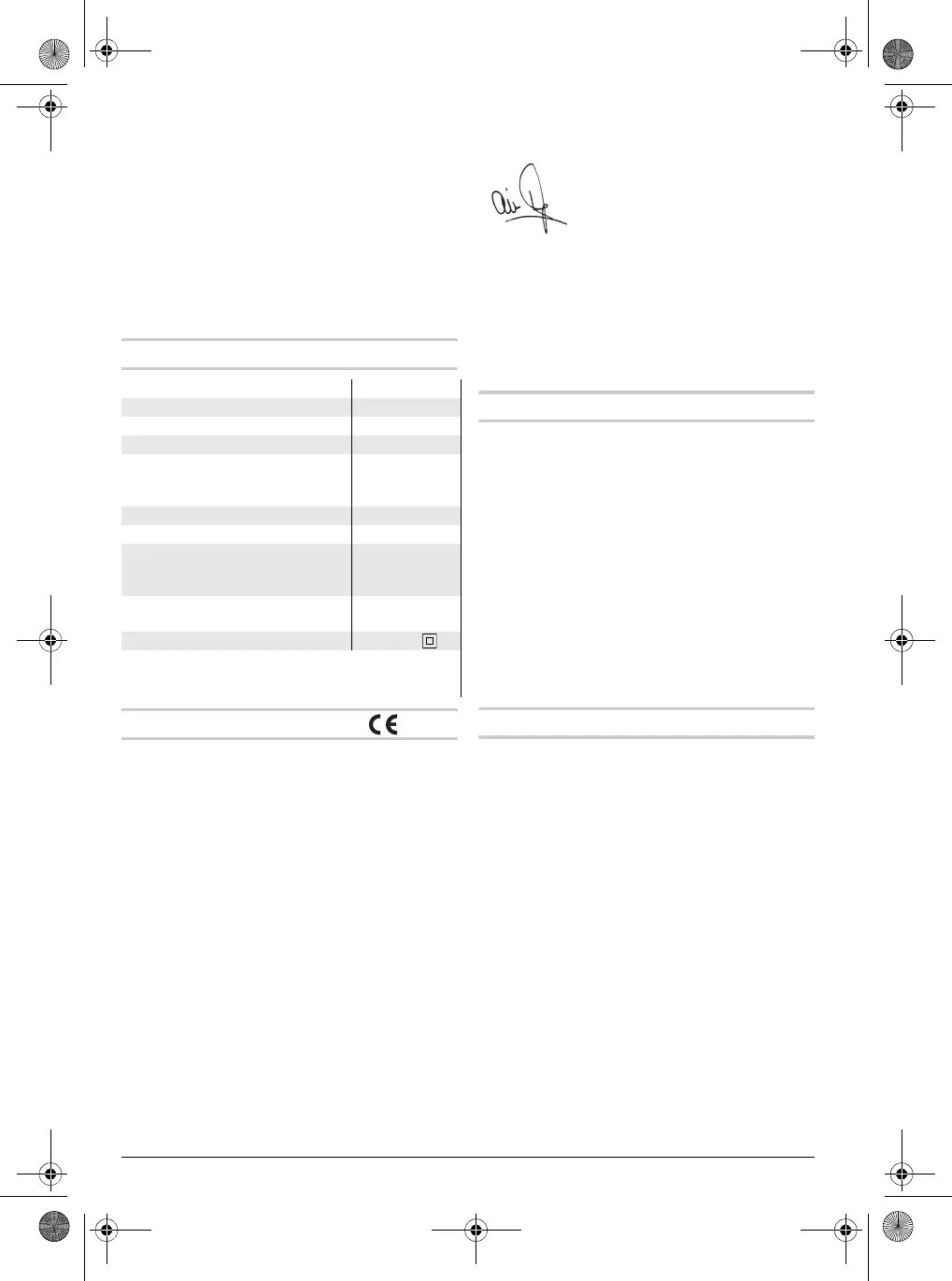

Technical Data

Declaration of Conformity

We declare under our sole responsibility that the

product described under “Technical Data” is in

conformity with all relevant provisions of the direc-

tives 2011/65/EU, until 19 April 2016:

2004/108/EC, from 20 April 2016 on:

2014/30/EU, 2006/42/EC, 2000/14/EC including

their amendments and complies with the following

standards: EN 60745-1, EN 60745-2-6.

2000/14/EC: Guaranteed sound power level 105.

Conformity assessment procedure according to

Annex VI.

Equipment category: 10

Notified body:

TÜV NORD CERT GmbH & Co. KG,

Am TÜV 1, 30519 Hannover

Technical file (2006/42/EC, 2000/14/EC) at:

Berner Trading Holding GmbH,

Bernerstraße 6,

74653 Künzelsau

GERMANY

25.06.2015, Berner Trading Holding GmbH

Bernerstraße 6

74653 Künzelsau

GERMANY

Assembly

Auxiliary Handle

Operate your machine only with the auxiliary

handle 7.

The auxiliary handle 7 can be set to any position for

a secure and low-fatigue working posture.

– Loosen the knurled nut 8, rotate the auxiliary

handle 7 around the axis of the machine to the

required position and tighten the knurled nut 8

again.

– The auxiliary handle 7 can be mounted to a dif-

ferent position. For this, completely unscrew the

knurled nut 8 and then pull out the hexagon bolt

upward. Pull off the auxiliary handle 7 to the side

and turn around the remaining clamping ele-

ment by 180 °. Mount the auxiliary handle 7 in re-

verse order.

Changing the Tool

Before any work on the machine itself, pull the

mains plug.

With the SDS-max tool holder, simpler and easier

tool changing is possible without additional aids.

The dust protection cap 1 largely prevents the pen-

etration of dust into the tool holder during opera-

tion. When inserting the tool, pay attention that the

dust protection cap 1 is not damaged.

A damaged dust protection cap should be

changed immediately. We recommend having

this carried out by an after-sales service.

Inserting (see figure A)

– Clean and lightly grease the shank end of the

tool.

– Insert the tool in a twisting manner into the tool

holder until it latches itself.

– Check the latching by pulling the tool.

Removing (see figure B)

– Push back the locking sleeve 2 and remove the

tool.

Demolition Hammer BCDH-11

Art. No. 000062

Rated power input W 1500

Impact rate min

-1

900 – 1890

Impact energy per

stroke according to

EPTA-Procedure 05/2009 J 16.8

Chisel positions 12

Tool holder SDS-max

Lubrication Central

permanent

lubrication

Weight according to EPTA-

Procedure 01:2014 kg 10.1

Protection class /II

The values given are valid for a nominal voltage [U] of

230 V. For different voltages and models for specific coun-

tries, these values can vary.

Armin Hess

Chairman of the Managemant Board

OBJ_BUCH-711-003.book Page 12 Thursday, July 23, 2015 4:30 PM

Loading...

Loading...