5.0 Selection of Spindles and speed:

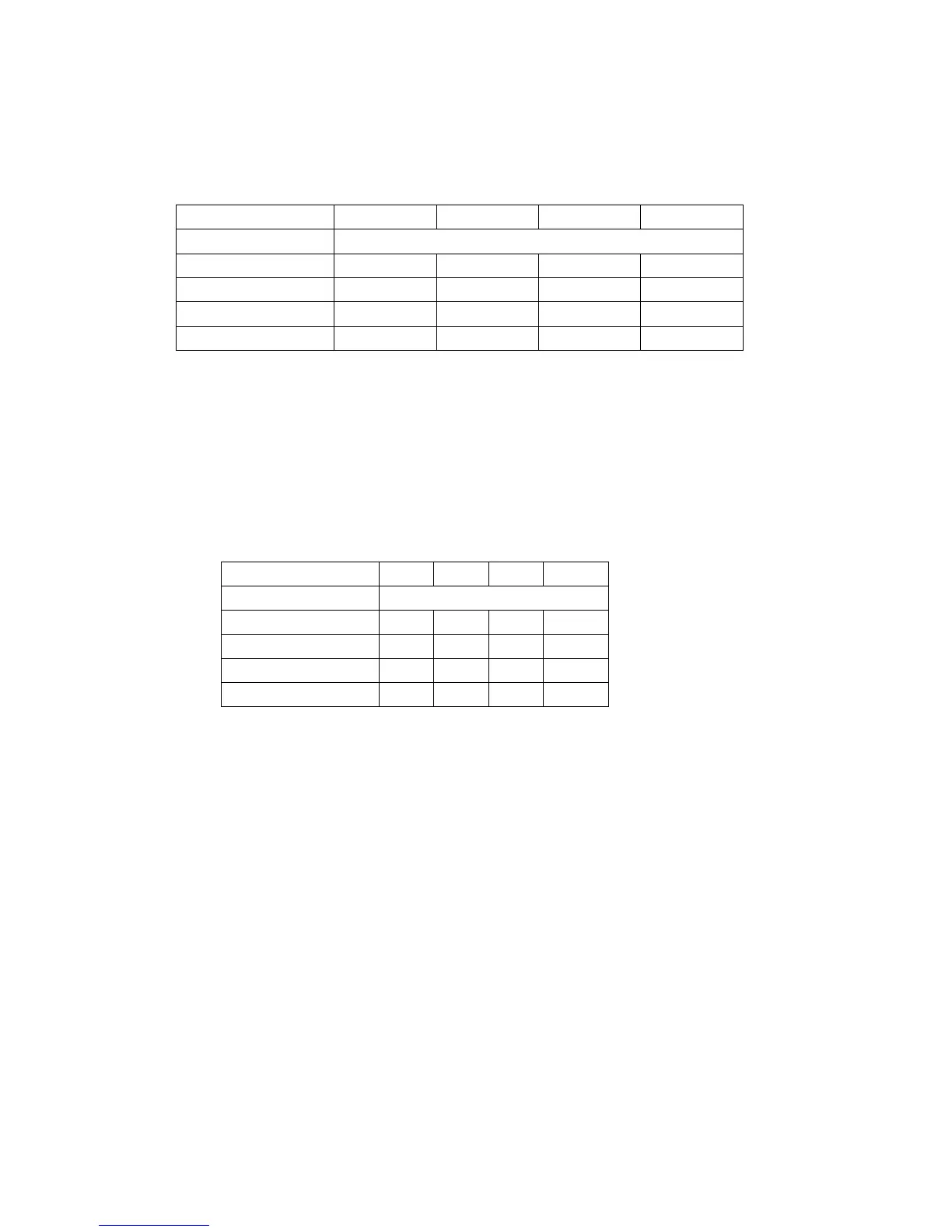

The principle of viscosity measurement not only takes into consideration of the viscometer rotation,

but also depends on the correct spindle to be used. The table as below give the correct use of spindle to

the viscosity measurement.

Rotation Speed →

60 30 12 6

Spindle Setting↓ Viscosity Reading in mPa.s

1 100 200 500 1,000

2 500 1,000 2,500 5,000

3 2,000 4,000 10,000 20,000

4 10,000 20,000 50,000 100,000

First, operator should estimate approximately the value of viscosity of their tested sample and select

appropriate spindle and rotation speed.

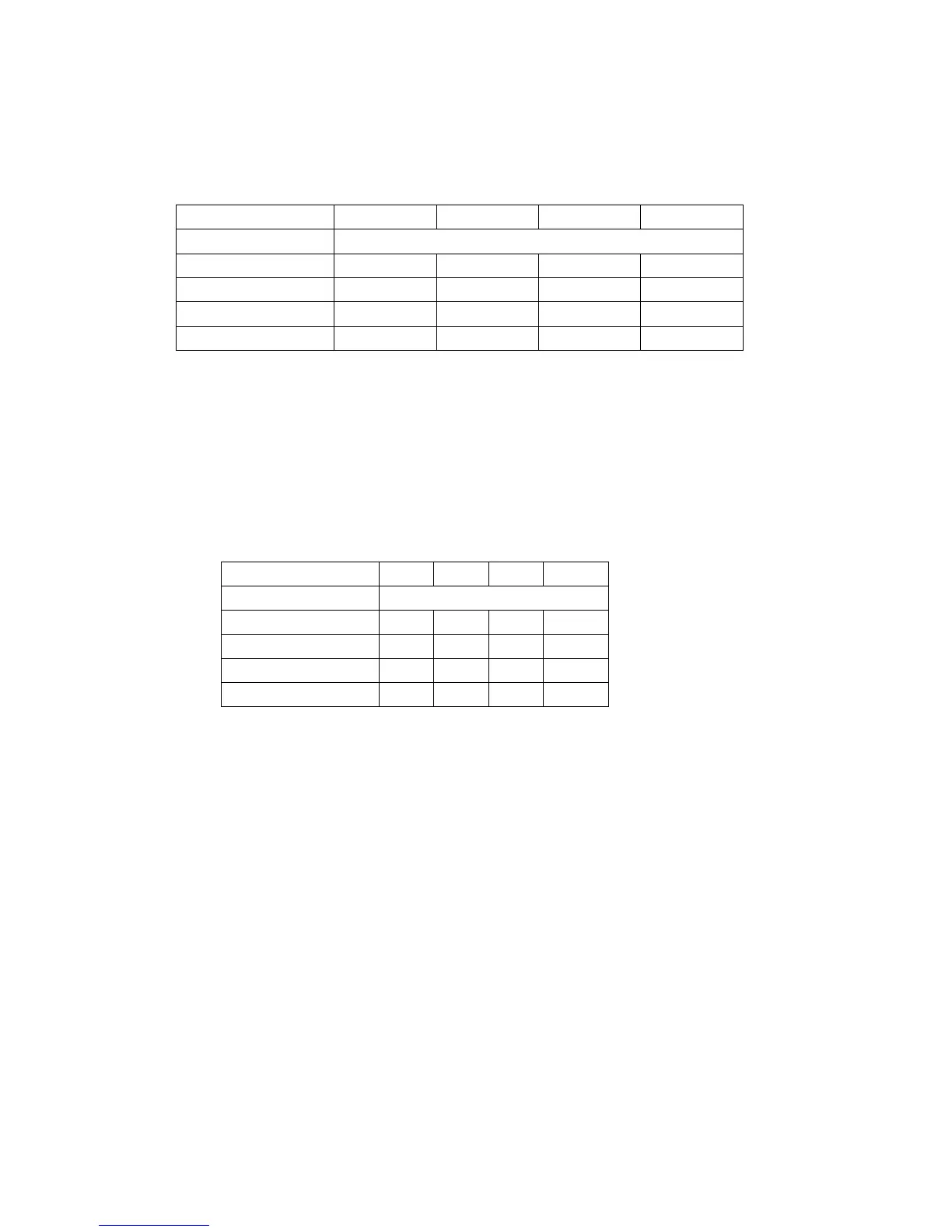

The Viscosity Correction Factor is described as follow:

η=K.a

Where η= Viscosity in mPa.s

K= Constant Factor

a= Reading at Viscometer

The K is decided by rotation speed and spindle jointly:

Rotation Speed →

60 30 12 6

Spindle Setting↓ K

1 1 2 5 10

2 5 10 25 50

3 20 40 100 200

4 100 200 500 1,000

6.0 Cautions:

6.1 The Machine must be used with prescriptive frequency and voltage. Otherwise the testing result will

be incorrect.

6.2 Change the rotation speed when the machine is working.

6.3 If you have installed the spindle, do not turn on the machine when no any fluid .

6.4 Do not disassembly the machine ad arboretum and do not add any lube on the gear wheel of

machine.

6.5 Install the yellow protecting sheath when conveying the machine.

6.6 Clean and dry the spindle carefully after every testing

7.0 Others

For more information regarding this product, spares, accessories etc. or if you would like a

catalogue listing our full range of products, please contact your local agent or Biuged Instruments at the

address on the following page.

Loading...

Loading...