Valve clearance should be 0.10-0.15 mm

(.004-.006")for Intake, and (0.10-0.20mm)

(.004-.008") for exhaust, with the engine cold.

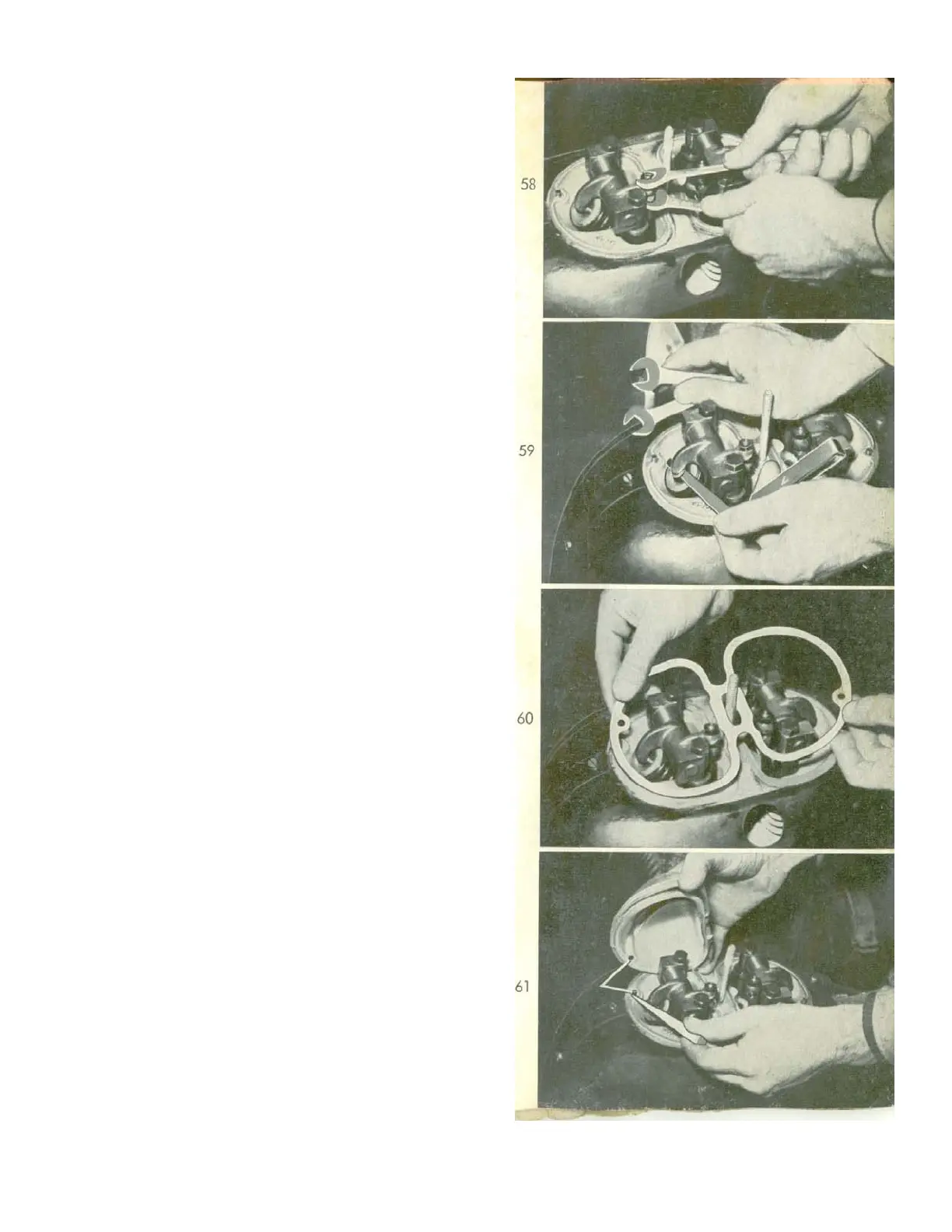

The adjustment and re-adjustment of the

valves requires two 12mm spanners. First

slacken the locknut (figure 58) then turn the

adjusting screw as required until the correct

amount of play is felt with the feeler-gauge

inserted between rocker arm and valve stem

end (figure 59). When this is obtained, hold

adjuster with its spanner and retighten the

locknut securely. When this nut is properly

tightened, check the play again, to make cer-

tain that it has not been altered while

tightening the nut.

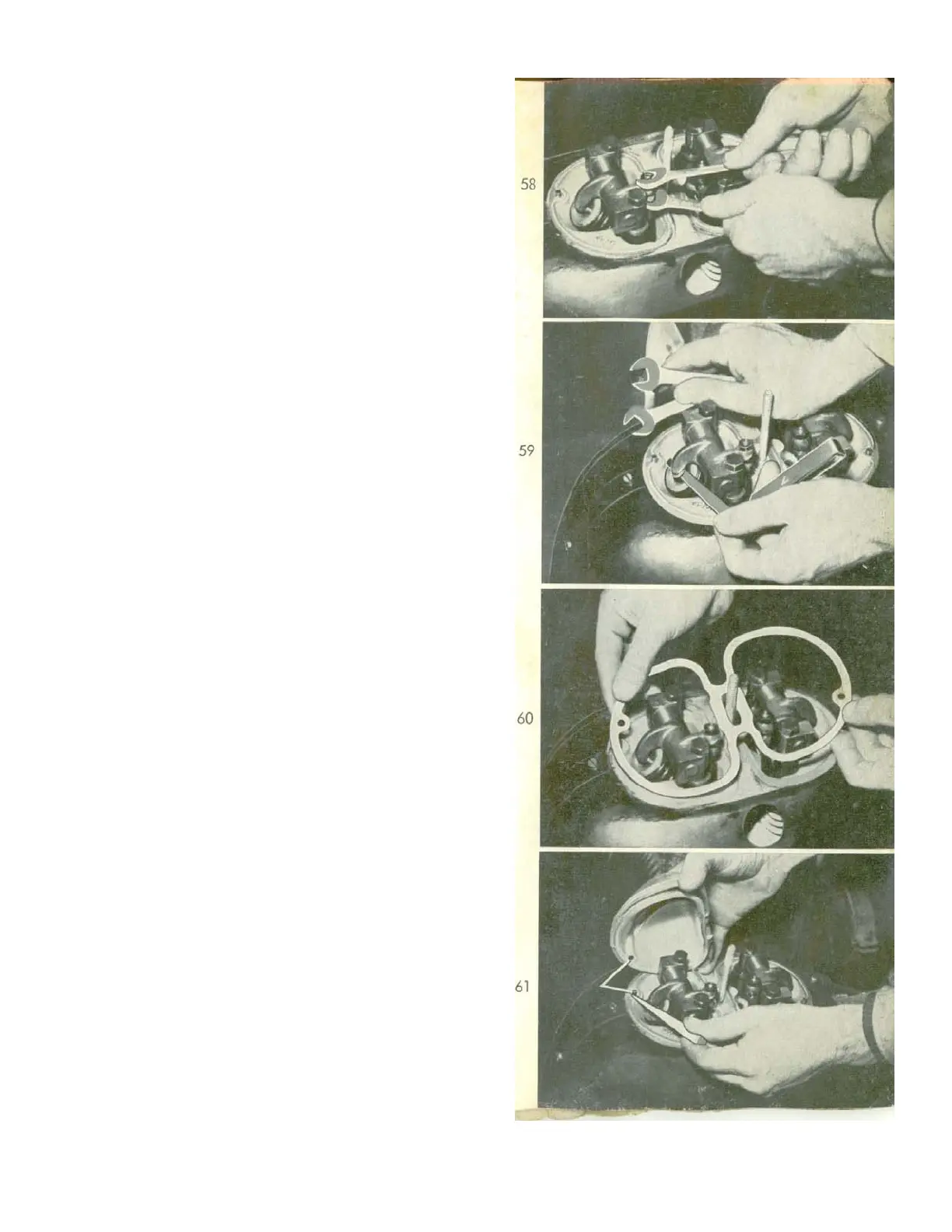

When adjusting the valves one should inspect

the rocker box cover gasket and replace it, if

necessary, in order to ensure the proper

sealing of rocker box (figure 60). Place the

gasket in a way that the two locating pins fit in

the two holes of the gasket. Special care

should be used in replacing the rocker

covers, so that the locating pins engage

exactly in the corresponding drilled holes

provided in these units. When the locating pin

is missed, and the cover is fitted incorrectly,

the gasket does not seal properly and the

consequences are deformation of the rocker

cover and continuous oil leakage (figure 61).

The figures illustrating the servicing of the

valves in this booklet are shown with the

engine in a complete accessible condition

after removal of the body. Normally, these

jobs are performed through the cover plate

located behind the seat squab, as shown on

figure 54.

24

Loading...

Loading...