Operation & Maintenance Manual–37–

331/331E/334 Excavator

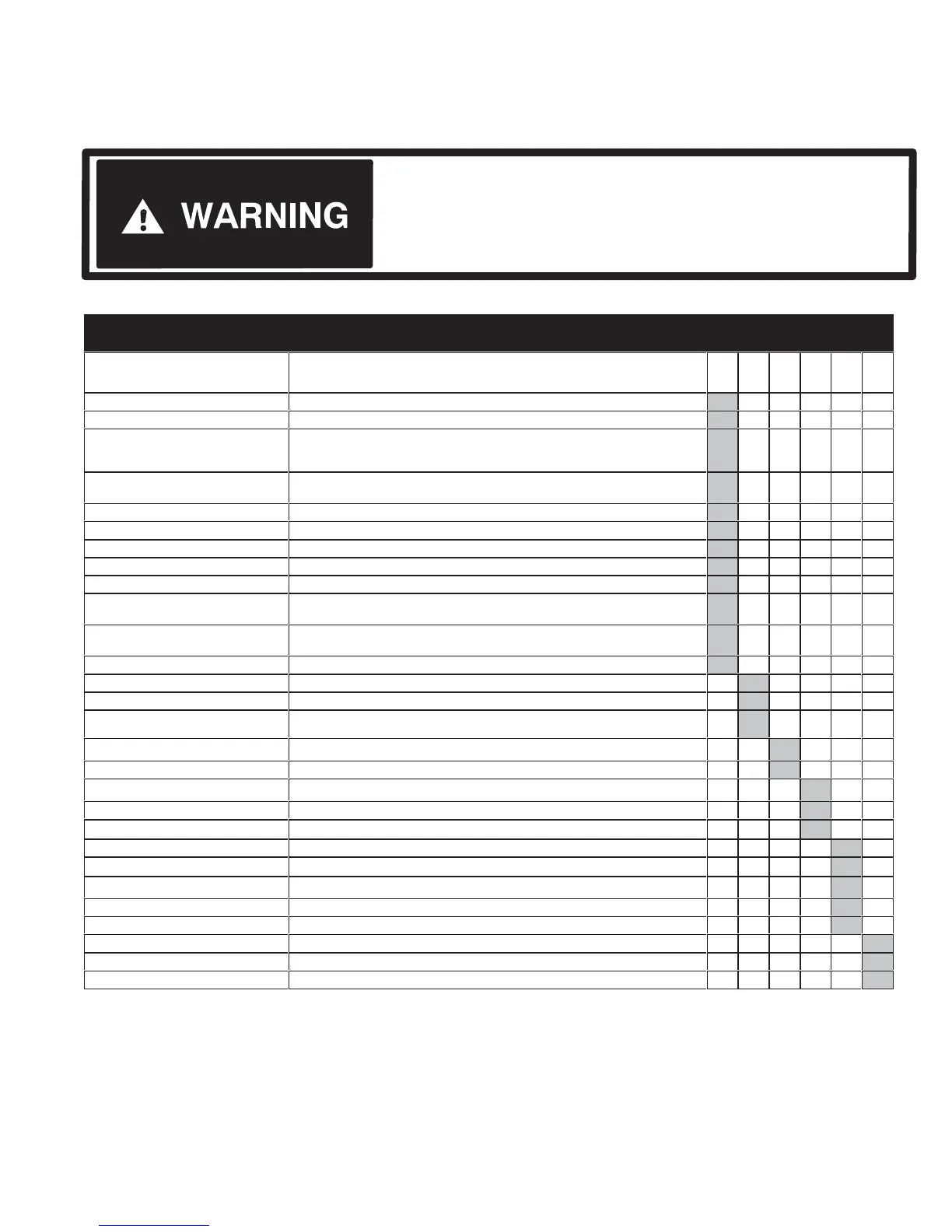

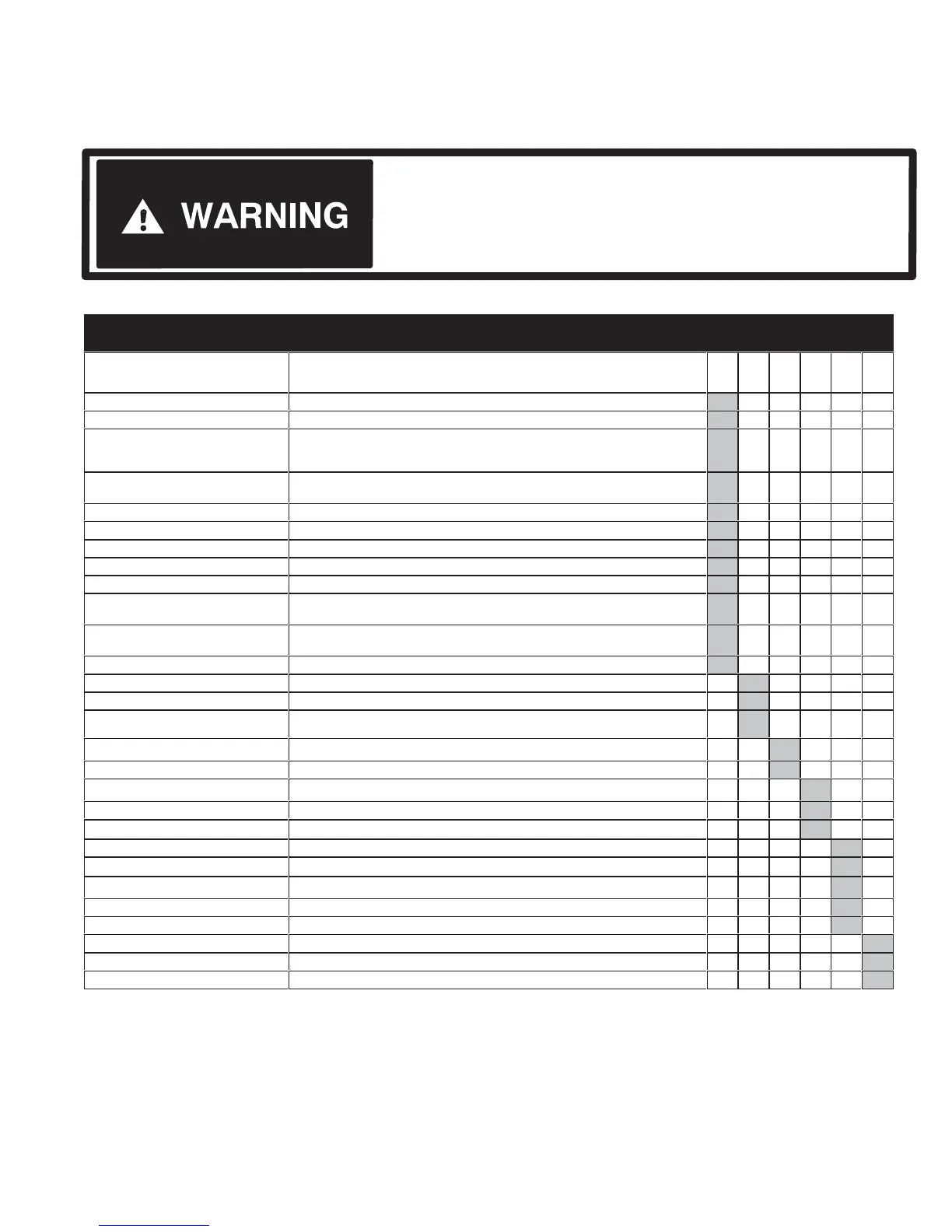

SERVICE SCHEDULE

Maintenance work must be done at regular intervals. Failure to do so will result in excessive wear and early failures. The

service schedule is a guide for correct maintenance of the Bobcat excavator.

SERVICE SCHEDULE

HOURS

ITEM SERVICE REQUIRED

8-10 50 100 250 500

n

1000

Engine Coolant Check coolant level. Add premixed coolant as needed.

Engine Oil Check the engine oil level and add as needed.

Hydraulic Fluid, Hoses and

Tubelines, Reservoir Breather

Cap

Check the hydraulic fluid level and add as needed. Check for

damage and leaks. Repair or replace as needed.

Engine Air Filter and Air

System

Check condition indicator and empty dust cup as needed. Check

air system for leaks.

Tracks Check and adjust track tension as needed.

Indicators and Lights Check for correct operation of all indicators and lights.

Operator Canopy / Cab Check condition. Check mounting hardware.

Seat Belt Check condition. Check mounting hardware.

Control Console Check lockouts for correct operation.

Safety Signs and Safety

Treads

Check for damaged signs (decals) and safety treads. Replace

any signs or safety treads that are damaged or worn.

Pivot Points Grease all machinery pivot points. (21 Places) Apply grease to

extendable arm (If Equipped).

Cab Heater Air Filter Clean the filter as needed.

Swing Circle and Pinion Grease three fittings.

Fuel Tank & Filter Drain water and sediment from fuel tank and fuel filter.

Battery Check battery, cables, connections and electrolyte level. Add

distilled water as needed.

Alternator / Fan Belt Check condition of belt and adjust as needed.

•

Spark Arrestor Muffler Clean the spark chamber.

Engine Oil and Filter Replace oil & filter. Use CD or better grade oil and Bobcat filter.

•

Fuel Filter Replace fuel filter.

Final Drive Case Check lubricant level in both final drive cases. ♦

Radiator, oil cooler, *A/C Clean debris from the radiator fins.

Hydraulic Filter Replace the filter element. ♦

Alternator & Starter Check the alternator and starter connections.

•

Engine Valves Check and adjust the engine valve clearance.

Case Drain Filter Replace the filter.

Final Drive Case Replace lubricant in both final drive cases.

Engine Cooling System Drain and flush the cooling system. Replace the coolant.

Hydraulic System Replace the hydraulic fluid and filter. Clean the Reservoir. ♦

* If Equipped

• Also at first 50 Hours

♦ Also at first 100 hours

n Or every 6 months.

W–2003–0199

Instructions are necessary before operating or servicing machine.

Read and understand the Operation & Maintenance Manual, Handbook

and signs (decals) on machine. Follow warnings and instructions in

the manuals when making repairs, adjustments or servicing. Check for

correct function after adjustments, repairs or service. Untrained

operators and failure to follow instructions can cause injury or death.

Loading...

Loading...