A

P–21160

1

C

P–21193

1

Operation & Maintenance Manual–44–

331/331E/334 Excavator

COOLING SYSTEM (Cont’d)

Replacing The Coolant

See the SERVICE SCHEDULE, Page 35 for the correct

service intervals.

Do not remove radiator cap when the engine is

hot. You can be seriously burned.

W–2070–1285

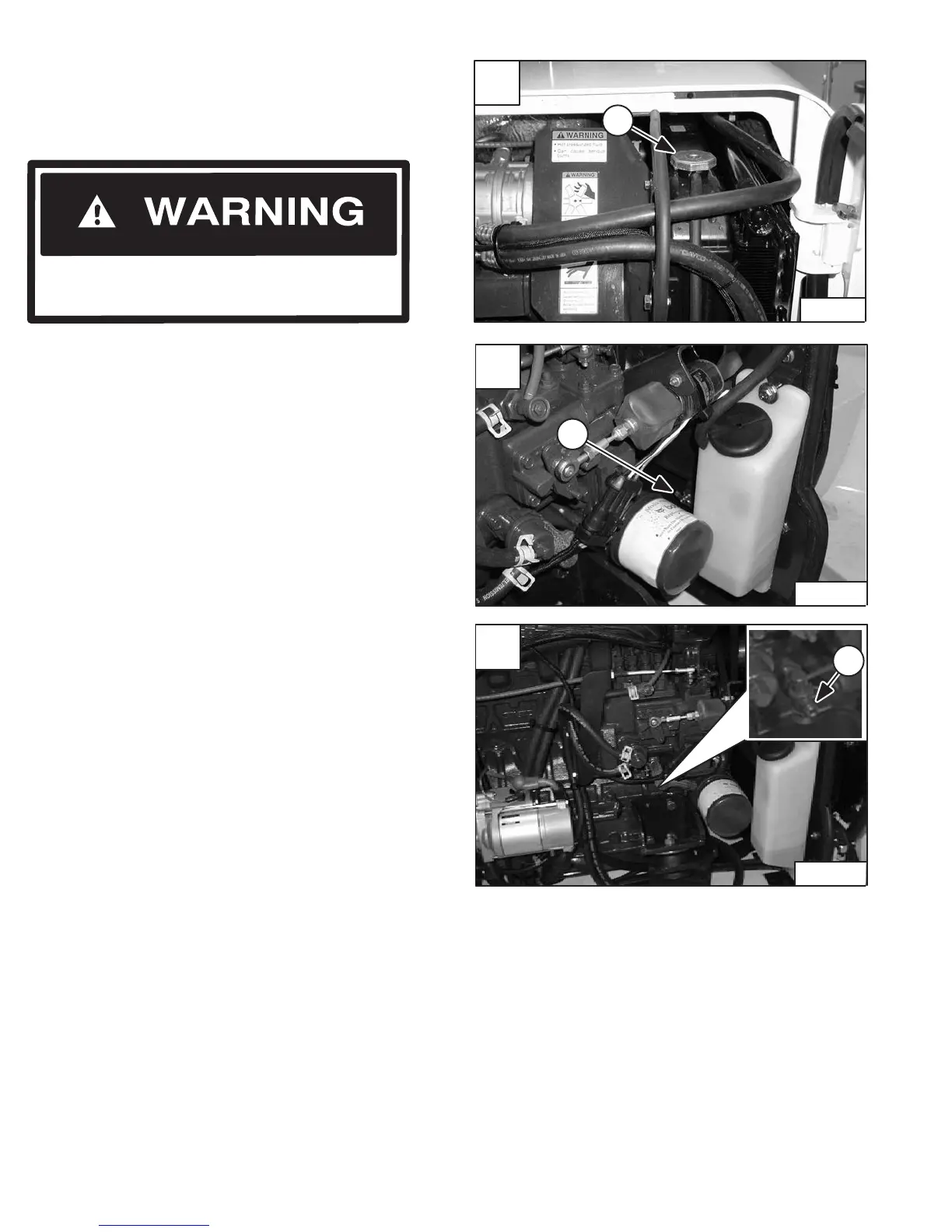

When the engine is cool, loosen and remove the radiator

cap (Item 1) [A].

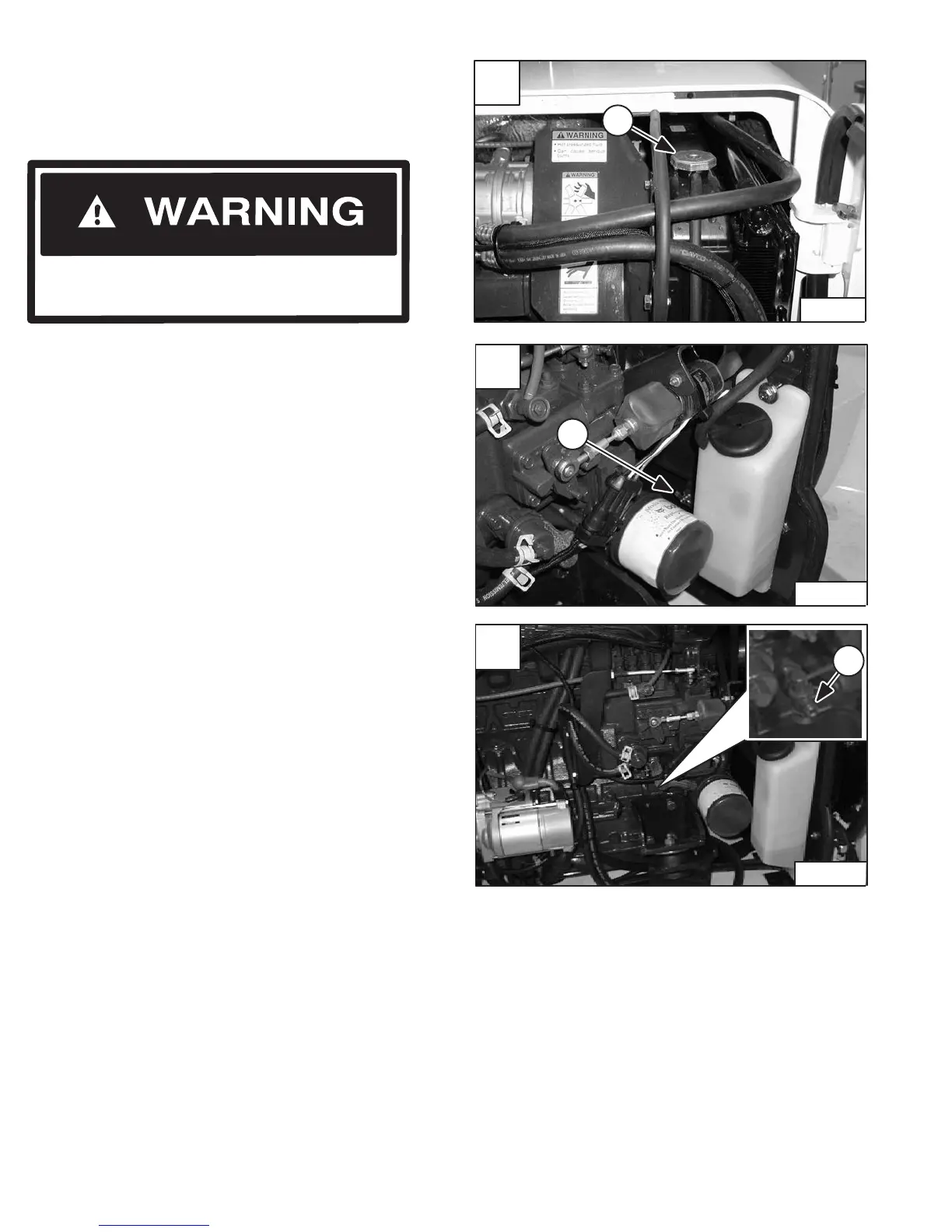

Put a hose on the drain valve at the bottom of the radiator.

Open the drain valve (Item 1) [B] and drain the coolant into

a container.

Put a hose on the drain valve on the engine block. Open the

drain valve (Item 1) [C] drain the coolant into a container.

After all the coolant is removed, close both drain valves.

Recycle or dispose of the used coolant in an

environmentally safe manner.

Mix the coolant in a separate container. (See FUEL,

COOLANT AND LUBRICANTS Chart, Page 81, for correct

capacity.)

NOTE: The cooling system is factory filled with

propylene glycol (purple color). DO NOT mix

propylene glycol with ethylene glycol.

Add premixed coolant; 47% water and 53% propylene

glycol to the recovery tank if the coolant level is low.

One gallon and one pint of propylene glycol mixed with one

gallon of water is the correct mixture of coolant to provide

a –34°F (–37°C) freeze protection. (See IMPORTANT,

Page 41.)

Use a refractometer to check the condition of propylene

glycol in your cooling system.

Add premixed coolant until the level is correct.

Run the engine until it is at operating temperature. Stop the

engine. Check the coolant level and add as needed. Be

sure the radiator cap is tight.

Add coolant to the recovery tank as needed.

Close the tailgate.

P–21156

1

B

P–21156

Loading...

Loading...