RE 64025-B/2021-08-12, Bosch Rexroth AG

Installation | Control blocks for mobile applications 29/54

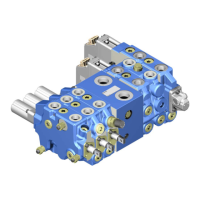

7�5�7 Connecting the control block hydraulically

CAUTION

Dangerous movements ofthe hydraulic consumers!

Risk ofinjury due toincorrect pin assignments ormixed up cable connectors

because ofinadvertent consumer movement!

Make sure that all the pipes and/or hoses have been attached to the correct

control block port and have not been mixed up under any circumstances.

After completing connection work, check that the cable connectors are

correctly assigned to the respective control block solenoids.

NOTICE

Damage due toimproper installation!

Hydraulic lines and hoses which are installed under tension create additional

mechanical forces during operation which reduce the service life of the control

block and the entire machine.

Install hydraulic lines and hoses without mechanical stress.

The machine manufacturer is responsible for dimensioning the lines. The control

block must be connected to the rest of the hydraulic system in accordance with

the hydraulic circuit diagram of the machine manufacturer.

The ports and fastening threads are designed forthe maximum pressure

specified inthe datasheet. The machine manufacturer must ensure that the

connecting elements and lines correspond to the specified application conditions

(pressure,flow, hydraulic fluid, temperature) with the necessary safety factors.

Only connect hydraulic lines that are appropriate for the control block port

(pressure level, size, system of units).

Observe the following notices when routing hydraulic lines.

• Lines and hoses must be installed without pre-charge pressure so that no further

mechanical forces are applied during operation that will reduce the service life of

the control block and possibly of the entire machine.

• Remove any resinification that has been created due to improper storage.

• Use suitable seals assealing material.

– Observe the sealing capability of the hydraulic fluid used.

– Use the provided seal at each hydraulic port.

– Pay attention to cleanliness and integrity of the connections.

• Make sure theconnections and connecting elements are airtight.

• Pressure lines

– For the pressure lines, use only pipes, hoses and connecting elements rated

for the working pressure range specified in the datasheet. These must also be

pressure resistant against the external air pressure.

• Drain line

– Always route the drain lines in a way that the control block is always filled with

hydraulic fluid and even during extended standstill periods cannot be emptied

hydraulically.

Notice onrouting oflines

Loading...

Loading...