30/54 Control blocks for mobile applications | Installation

Bosch Rexroth AG, RE 64025-B/2021-08-12

The control blocks are used in application areas with metric as well as with the

Anglo-American (inch) system of units.

Both the system of units as well as the size of the female thread and stud end

(e.g.threaded plug) must match.

There isarisk ofconfusion due tothe limited ways ofvisually telling them apart.

Observe the parameters contained in the offer drawing. Unless otherwise stated,

in general the SI units apply.

WARNING! Leaky orbursting stud ends!

If a stud end which is of a different measurement system and size with respect to

the female thread is pressurized, the threaded plug may loosen itself or even be

ejected from the stud end in a projectile-like manner. This can result inserious

injury and property damage. Hydraulic fluid can escape from this leakage point.

Use the drawings (offer drawing) to determine the required stud end for each

fitting.

Ensure that, during the assembly of fittings, mounting and threaded plugs, the

items are not confused.

For all female threads, use astud end from thesame system ofunits and

ofthecorrect size.

For an overview ofline connections, refer tothe respective datasheetand the

offer drawing.

Observe the parameters in the standards or the manufacturer's specifications for

the stud ends, fittings and threaded plugs on hydraulic ports. Apart from this, be

aware that tightening torques can also depend on the permissible pressure and

temperature range and the application conditions.

To connect the control block to the hydraulic system:

1� Remove theprotective plugs orthreaded plugs from theports where

theconnections should be made according tothe hydraulic circuit diagram.

2� Make sure thesealing surfaces ofthehydraulic ports and functional surfaces

are not damaged.

3� Use only clean hydraulic lines orflush them before installation.

4� Connect the lines according tothe offer drawing supplied with the machine

diagram. Check whether all ports are piped up orplugged with threaded plugs.

5� Properly tighten thefittings (observe tightening torques!). Mark all properly

tightened fittings, e.g.with apermanent marker.

6� Check all pipes and hose lines and every combination ofconnecting pieces,

couplings orconnecting points with hoses orpipes toensure they are insafe

working condition.

Risk ofconfusion with

threaded connections

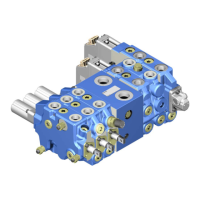

Port overview

Tightening torques

Procedure

Loading...

Loading...