If blade bolts are allowed to run loose, the obvious danger is for the bolt to come completely loose,

allowing the blade, bolt, and nut to be ejected from the cutter.

Tightening Blade Bolts (continued)

The second danger is that when the bolt is not sufciently tight, the blade is allowed excess vertical

movement when it strikes an object, be it something it will cut or something into which it should not

come in contact. In this situation, the blade is being hammered against the blade carrier and exed, or

bent, up around the edge of the blade carrier at least twelve (12) times per second, generally fteen (15)

times per second. This situation will

cause the blade to break from fatigue

and to be ejected from the cutter.

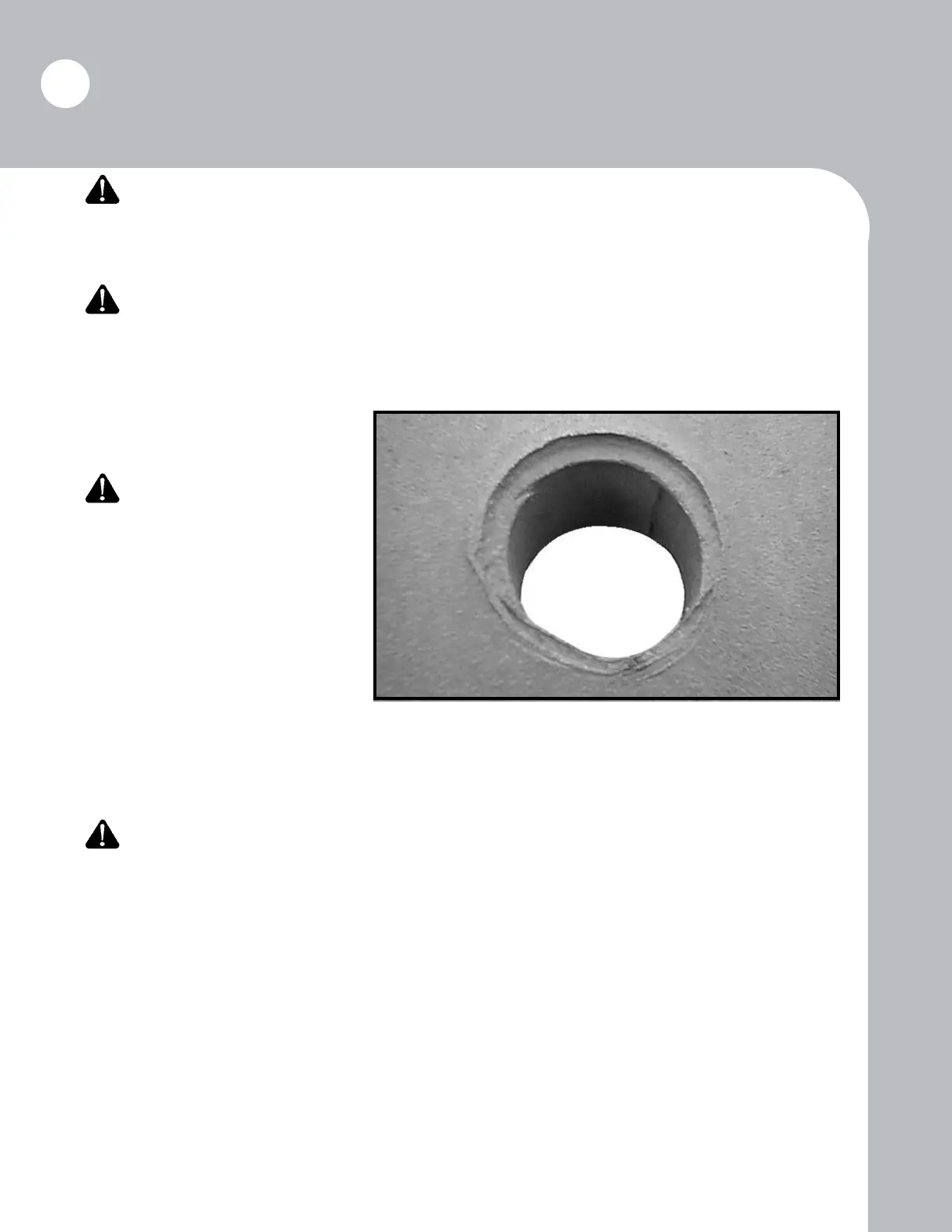

The third danger is that, while

the second situation is occurring,

the blade bolt is also hammering the

underside of the blade carrier; the

shoulder of the blade bolt beats an

indention around the blade bolt hole

into which the bolt shoulder will t.

When this damage occurs, the blade

bolt will pull up into the indention

when the bolt is tightened, causing

the blade to jam so that it can no longer pivot on the blade bolt. A jammed blade will break either from

fatigue or from catastrophic occurrence and will allow the blade to be ejected. A blade carrier damaged

in this manner must be taken out of service immediately. Repair the blade carrier (contact Brown Mfg.

Corp. for instructions) and replace the blades and blade bolts before returning the machine to service.

All three of the described occurrences will cause the blades to break and be ejected. An

ejected blade can and will cause serious injury or death.

REMEMBER: Blades must pivot freely and blade bolts must be tight!

Maintenance

34

Loading...

Loading...