MAINTENANCE PROCEDURES

On approved studded tracks, replace

broken or dam aged studs immediately.

If your track shows signs of deteriora-

tion, it must be replaced immediately.

When in doubt, ask your dealer.

WARNING

Riding with a damaged track or

studs could lead to a loss of con-

trol, resulting in a risk of serious

injury or death.

For complete information on traction

enhancing products, refer to the sec-

tion entitled

TRACTION ENHANCING

PRODUCTS

in the

SAFETY INFORMA-

TION

section at the beginning of this

Operator's Guide.

Track Tension and Alignment

NOTE: Track tension and alig nment

are interrelated. Do not adjust one

without the other.

WARNING

To prevent serious injury to indi-

viduals near the snowmobile:

– NEVER stand behind or near a

moving track.

– Always use a wide-base snow-

mobile stand with a rear deflec-

torpanelifitisnecessarytoro-

tate track.

– When the track is raised off the

ground, only run it at the lowest

possible speed.

Centrifugal force could cause de-

bris, pieces of torn track, or an en-

tire severed track to be violently

thrown backwards out of the tun-

nel with tremendous force.

Track Tension Verification

NOTE: Ride the snowmobile in snow

about 15 to 20 minutes prior to

adjust-

ing track tension.

1. Remove tether cord cap from e

n-

gine cut-off switch.

2. Lift rear of vehicle and support it off

the ground.

CAUTION Use proper lifting

techniques, notably using your legs

force. Do not attem pt to lift the rear

of vehicle if it is above your limits.

3. Allow rear suspension to fully ex-

tend.

4. Use the TENSIOMETER (P/N 414

348 200).

414348200

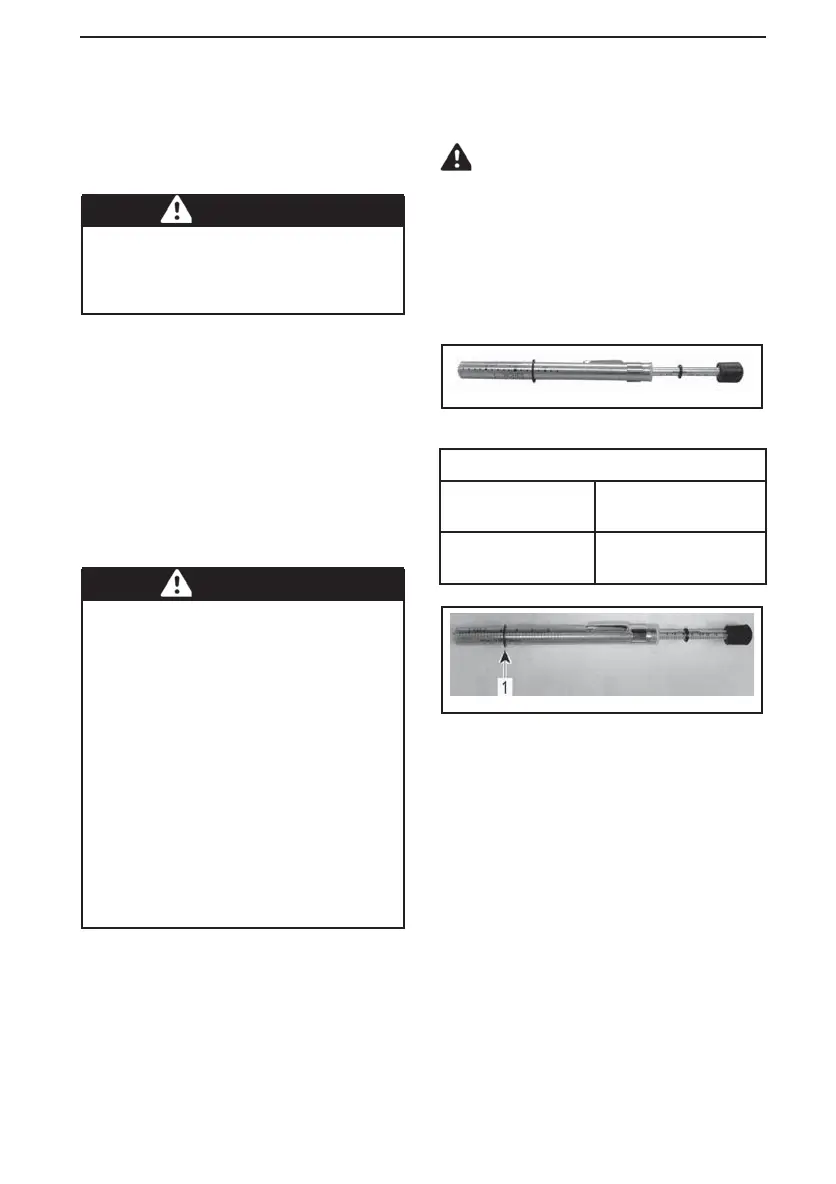

5. Set deflection using bottom O-ring.

DEFLECTION

EasyRide

suspension

40 mm to 45 mm

(1.575 in to 1.772 in)

All other models

40 mm to 50 mm

(1.5 in to 2 in)

mmr2009-133-003_b

DEFLECTION SETTING

1. Bottom O-ring set to specification

6. Place upper O-ring to 0 kgf (0 lbf).

7. Position the tensiometer on track,

halfway between front and rear idler

wheels.

8. Push the tensiometer downwards

until bottom O-ring (deflection) be

aligned with the bottom of slider

shoe.

______________

117

Loading...

Loading...