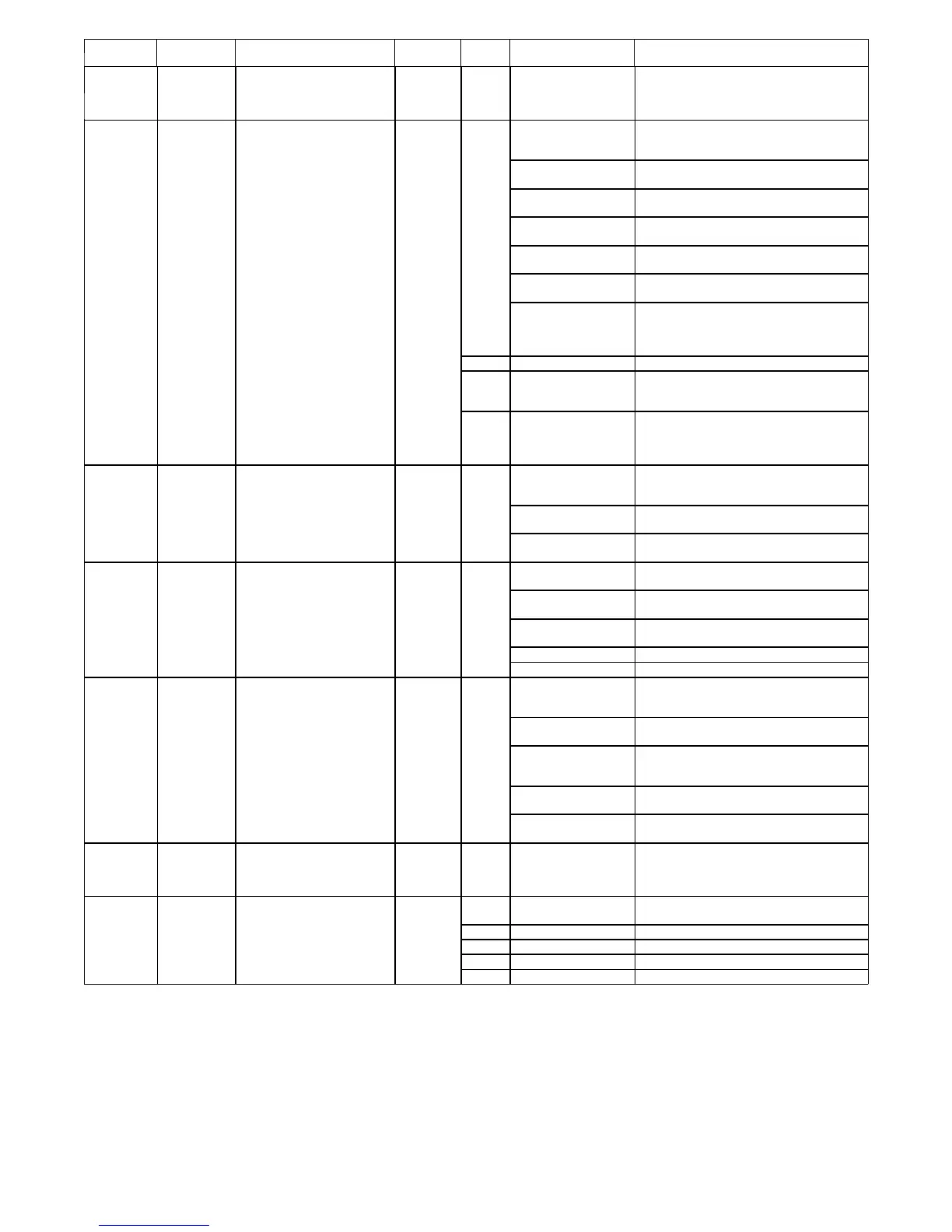

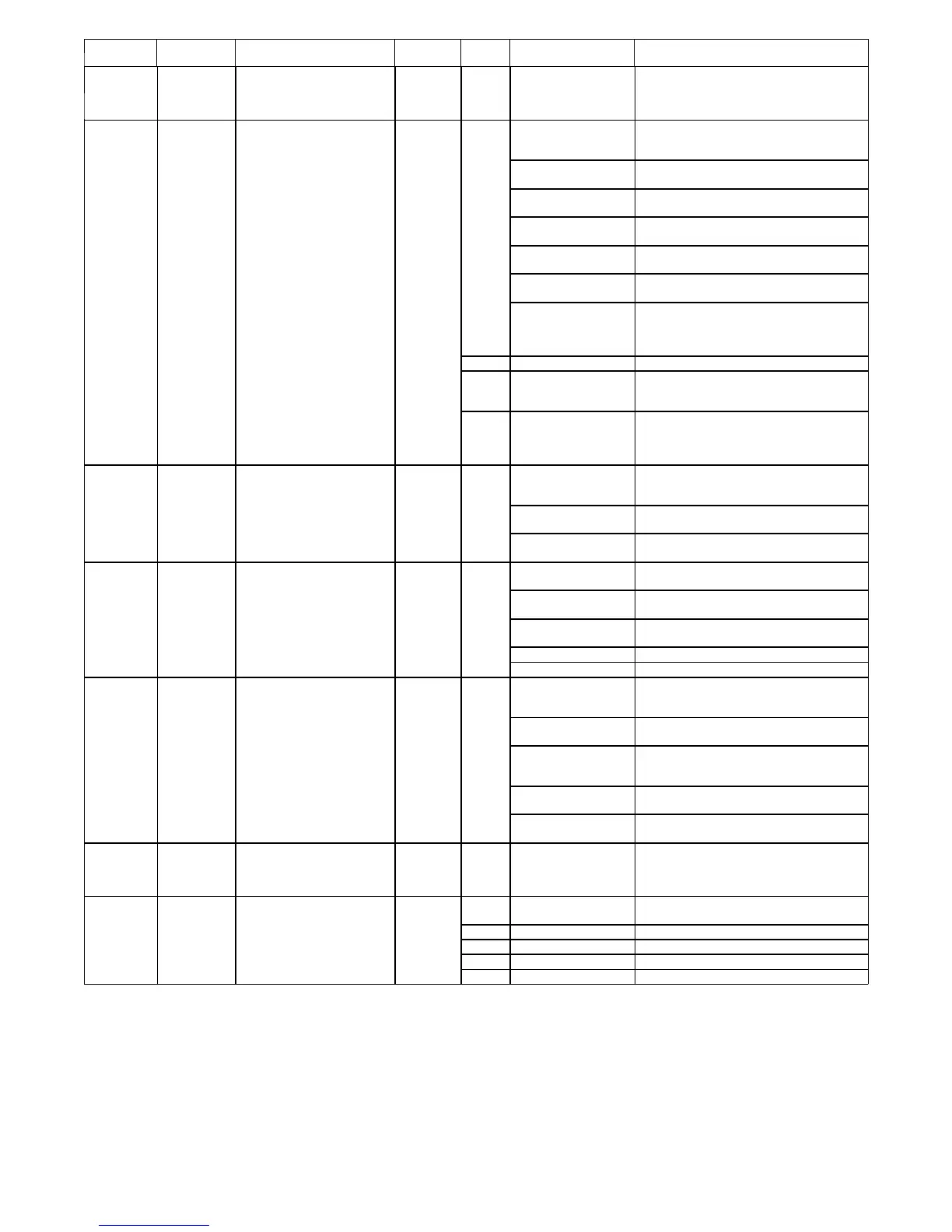

20

Flash

Code

ActionsPossible CausesMode

Reset

Time

Amber LED DescriptionTy p e

72 Local

SUCTION OVER TEMPERA-

TURE EVENT

(elevates to fault code 82 after

3 occurrences)

15 Minutes Both See fault 82 Same actions for 82

74

System

Malfunction

DISCHARGE TEMP OUT OF

RANGE LOCKOUT

(Elevated from fault code 59 af-

ter 5 occurrences)

2 Hours

Both

Sensor Harness not

connected to AOC

control

Ensure plug is connected to AOC control

Broken or loose

harness wire

Check harness for continuity; see resistance

chart to check resistance at given temperature

Broken or Damaged

Sensor

Check harness for continuity; see resistance

chart to check resistance at given temperature

Hardware damage to

AOC control

Replace AOC control

Indoor Unit Airflow too

low or off

Troubleshoot indoor fan motor and make sure

it is working

Outdoor Unit Airflow too

low or off

Troubleshoot outdoor fan motor and make

sure it is working

Reversing Valve By-

pass or Reversing

Valve not energized

Reversing Valve stuck halfway

Ensure AOC fuse is good

24 VDC in cooling mode

Check harness and connectors

Cool High Load conditions Over charge: Check system charge

Heat

Low Charge or Loss of

Charge at low ambient

heating conditions

Undercharged or No charge: check charge

Heat

Expansion Device

Restriction

Heating: Trouble shoot EXV (coil, harnesses);

Trouble shoot the TXV

Power Cycle system, is EXV moving on power

up (audible)

75 Local

MAXIMUM POWER MODE -

TEMP

(Temporary RPM reduction or

stage lowering will result.)

NA Both

Outdoor Airflow too low

or off

Check ODU coil for clogging (ice or debris)

and clean if necessary; Troubleshoot ODU fan

motor and make sure it is working

Blocked Inverter Heat

Exchanger (fins)

Check Inverter fins for debris and clean if nec-

essary

Application violates

guideline

Consult Application Guideline for compliance

76

System

Malfunction

FAN INVERTER LOCKOUT

(Elevated from fault code 61

after 5 occurrences)

2 Hours Both

Fan blade bent/out of

balance

Check outdoor fan blade

Check for ice build up

Fan blade restricted

Check outdoor fan blade clearance

Check for ice build up

Fan motor wiring

Check outdoor fan motor connectors and har-

ness

Fan motor Replace outdoor fan motor

Inverter damage Replace inverter

77 Local

MAXIMUM POWER MODE -

COMP CURRENT

(Temporary RPM reduction or

stage lowering will result.

NA Both

Compressor is operat-

ing outside the allowed

operational envelope

Inverter will reduce speed to a lower stage

Incorrect refrigerant

charge

Check refrigerant amount

Outdoor Airflow too low

or off

Check ODU coil for clogging (ice or debris)

and clean if necessary; Troubleshoot ODU fan

motor and make sure it is working

Incoming power supply

voltage

Check voltage versus unit rating plate for

allowable range

Loose or incorrect wire

connections

Check incoming power leads and leads to the

compressor plug

79 Local

COMPRESSOR/INVERTER

FAULT

(Elevates to fault code 88 after

5 occurrences)

6 Minutes Both

Compressor fails to

start

System will try to self-mitigate with repeated

start attempts

82

System Mal-

function

SUCTION OVER TEMP

LOCKOUT

(Elevated from fault code 72 af-

ter 3 occurrences)

4 Hours

Both

Incorrect refrigerant

charge

Check refrigerant amount

Cool Uninsulated vapor line Insulate the vapor line

Cool Indoor TXV operation Troubleshoot TXV

Heat Outdoor EXV operation Troubleshoot EXV

Both Reversing valve bypass troubleshoot reversing valve

Loading...

Loading...