Do you have a question about the Car Oil System RPB 35.11 and is the answer not in the manual?

| Brand | Car Oil System |

|---|---|

| Model | RPB 35.11 |

| Category | Lifting Systems |

| Language | English |

Explains hazard symbols and their meanings for safe operation.

Details the operation and components of the remote control unit.

Illustrates the procedure for using emergency manual controls.

Identifies the physical locations of various sensors on the lift system.

Explains the operational procedures related to sensor activation and system response.

Details how to adjust the platform's stowing angle for proper cassette entry.

Explains how to set the recommended platform slope for optimal performance.

Details the procedure for calibrating the pressure switch for correct operation.

Procedures to check for platform strain, drift, and overload as per standards.

Verifies full operation of ascent and descent with maximum payload.

Instructions for regular inspections and maintenance by authorized personnel.

Verifies the correct operation of the lift through cycles.

Ensures the hydraulic oil level in the tank is within the correct range.

Checks and lubricates key components according to the schedule.

Provides general instructions and warnings for replacing the complete lift.

Details the procedure for inverting pipe and cable routing from the cassette.

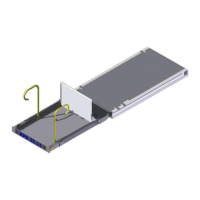

Explains how to dismount the mobile carriage, including arms and platform.

Outlines procedures for calibrating angles and pressure switch for proper operation.

Loading...

Loading...