10

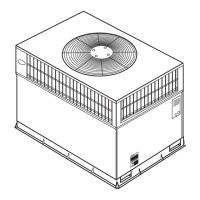

50SZ CORNER WEIGHTS AND SUGGESTED RIGGING

x

y

1

2

3

4

C00071

DETAIL A

A05161

CORNER WEIGHTS (SMALL CABINET) Lbs. CORNER WEIGHTS (LARGE CABINET) Lbs.

Unit 024 030 Unit 036 042 048 060

Total Weight 343 366 Total Weight 433 460 480 492

Corner Weight 1 69 74 Corner Weight 1 87 93 97 99

Corner Weight 2 53 57 Corner Weight 2 68 72 74 76

Corner Weight 3 83 88 Corner Weight 3 104 111 116 119

Corner Weight 4 138 147 Corner Weight 4 174 184 193 198

Rigging Weight 353 376 Rigging Weight 443 470 490 502

Shipping Weight 373 396 Shipping Weight 463 490 510 522

SELECTION PROCEDURE (WITH E XAMPLE)

I. Determine cooling and heating requirements of design condi-

tions:

Given:

Required Cooling Capacity (TC) 28,000 Btuh..............

Sensible Heat Capacity (SHC) 20,500 Btuh................

Required Heating Capacity (SHC) 28,550 Btuh.............

Outdoor Entering Air Temperature 95°F(35°C).............

Outdoor--Air Winter Design Temperature 20°F(--6.6°C).......

Indoor-- Air Winter Design Temperature 70°F (21.1°C)........

Indoor Entering --Air Temperature 80°F (26.6°C).............

67°F (19.4°C) ewb

Indoor-- Air Quantity 1125 cfm..........................

External Static Pressure 0.20 in. wc.......................

Electrical Characteristics (V--Ph--Hz) 230--1--60.............

edb ⎯ entering dry bulb

ewb ⎯ entering wet bulb

II. Select unit based on required cooling capacity.

Enter Cooling Extended Performance table at outdoor entering --air

temperature of 95_F(35°C), indoor air entering at 1125 cfm and

67_F (19.4°C) ewb (entering wetbulb). Theunit will provide a total

cooling capacity of 30,900 Btuh and a sensible heat capacity of

24,800 Btuh.

For indoor--air temperature other than 80_F (26.6°C) edb (entering

dry bulb), calculate sensible heat capacity correction, as required,

using the formula found in Note 3 following the cooling capacities

tables. NOTE: Unit ratings are net capacities.

III. Select electric heat.

Enter the unit Heating Extended Performance table at 1125 cfm. At

70_F (21.1°C) returnindoorair and 20_F(--6.6°C) airentering out-

door coil, the integrated heating capacity is 16,200 Btuh. (Select in-

tegrated heating capacity value since deductions for outdoor--coil

frost and defrost have already been made. No correction is required.)

The required heating capacity is 28,550 Btuh. Therefore, 12,350

Btuh (28,550 -- 16,200) additional electric heat is required.

Determine additional electric heat capacity in kW.

12,350 Btuh

= 3.6 kW of heat required

3,414 Btuh/kW

Enter the Electric Heater table on page 5 for 208/230 v, single--

phase,unit.The5--kW heaterat240 v most closely satisfies the heat-

ing required. To calculate kW at 230 v, multiply the heater kW by

multiplication factor 0.92 found in the Multiplication Factors table

on page 17.

5 kW x 0.92 = 4.6 kW

4.6 kW x 3414 = 15,704 Btuh

Total unit heating capacity is 31,900 Btuh (16,200 + 15,704).

IV. Determine fan speed and power requirements at design condi-

tions.

Before entering the air delivery tables, calculate the total static pres-

sure required.

50SZ

Loading...

Loading...