37

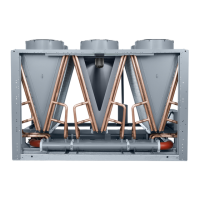

Fig. 35 — Typical Parallel Master/Slave Chillers

Common Primary Pumping, Variable Flow, Entering Water Control

Table 28 — Master Chiller Configuration in Series Applications

DISPLAY NAME PATH VALUE

Master/Slave Select

Main Menu

Configuration Menu

Master/Slave Config

1 (Master)

Default: 0 (Disable)

Master Control Type

1=Local Control

2=Remote Control

3=CCN Control

Default: 1(Local)

Configure for proper control type.

Slave Address

Must be set to the Slave Chiller’s address.

The Master and Slave chiller must have

different addresses and be on the same

Bus Number

Default: 2

Lead Lag Select

0 (Master Always Leads)

1 (Lag One Failed Only)

2 (Lead/Lag Runtime Select)

Default: 0 (Master Always Leads)

Lead/Lag Balance Delta

Range: 40 to 400 hours

Default: 168 hours

Lead/Lag Start Timer

Range: 2 to 30 minutes

Default: 10 minutes

Lead Pulldown Time

Range: 0 to 60 minutes

Default: 0 minutes

Start If Error Higher

Range: 3.0 to 18°F (1.7 to 10.0°C)

Default: 4.0°F (2.2°C)

Lag Minimum Running Time

Range: 0 to 150 minutes

Default: 0 minutes

Lag Unit Pump Control

0 (Stop If Unit Stops)

1 (Run If Unit Stops)

Default: 0 (Stop If Unit Stops)

Chiller In Series

Yes (In Series)

Default: No

CONTROL BOX

SLAVE

CHILLER

CONTROL BOX

MASTER

CHILLER

LOAD

ISOLATION VALVES

FIELD WIRING

FIELD COMMUNICATION WIRING

NOTE: This is a simplified piping diagram.

Not all hydronic specialties are shown.

MASTER

PUMP

ISOLATION VALVES

Loading...

Loading...