38GLS…G / 38YL-…G Puron

GB - 7

ENGLISH

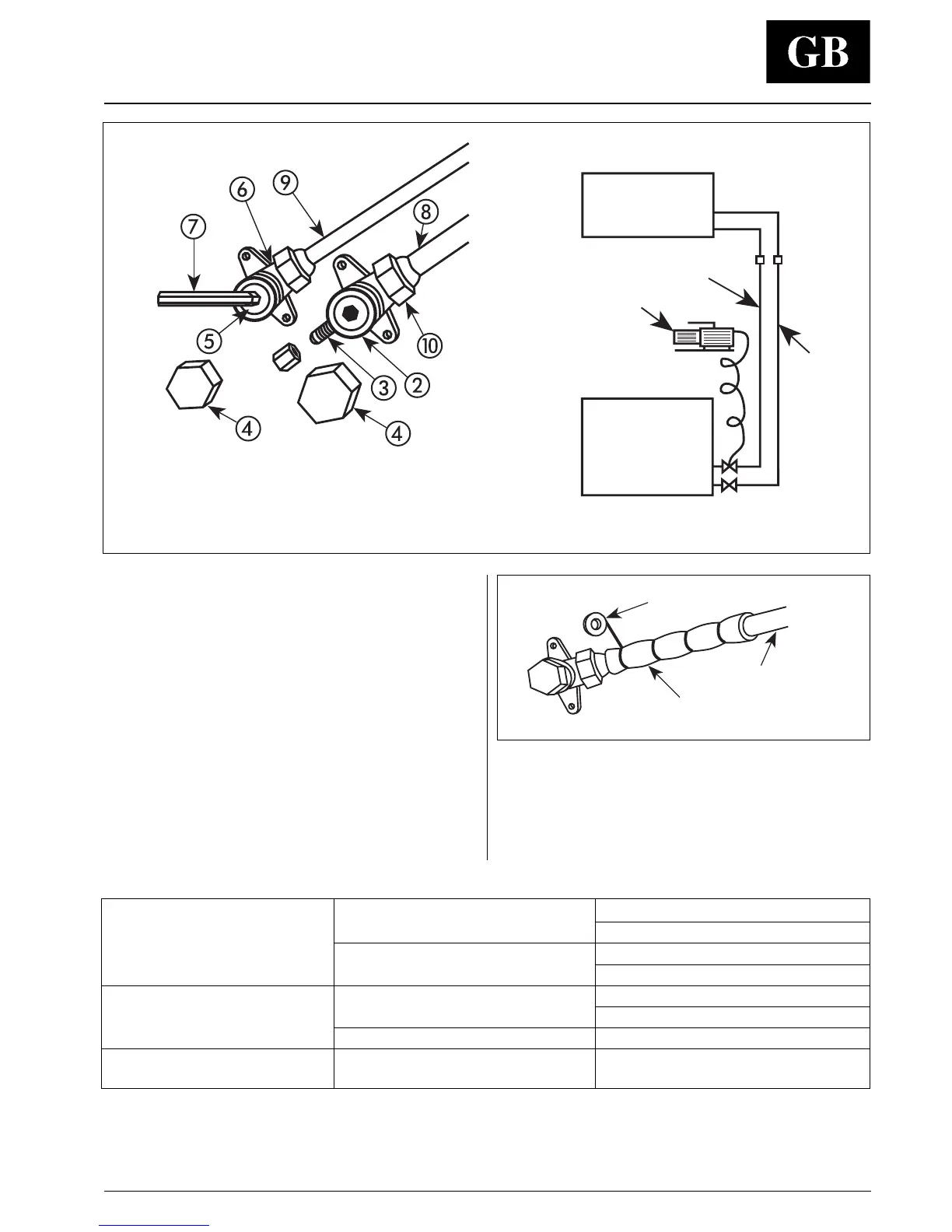

햹 Gas line (large diameter)

햺 Liquid line (small diameter)

햻 Flare nut

햽 Indoor unit

햾 Outdoor unit

햿 Vacuum pump

햳 Three-way valve

햴 Needle valve

햵 Valve cap

햶 Valve needle

햷 Two-way valve

햸 Allen (hex. head) wrench

Refrigerant connections

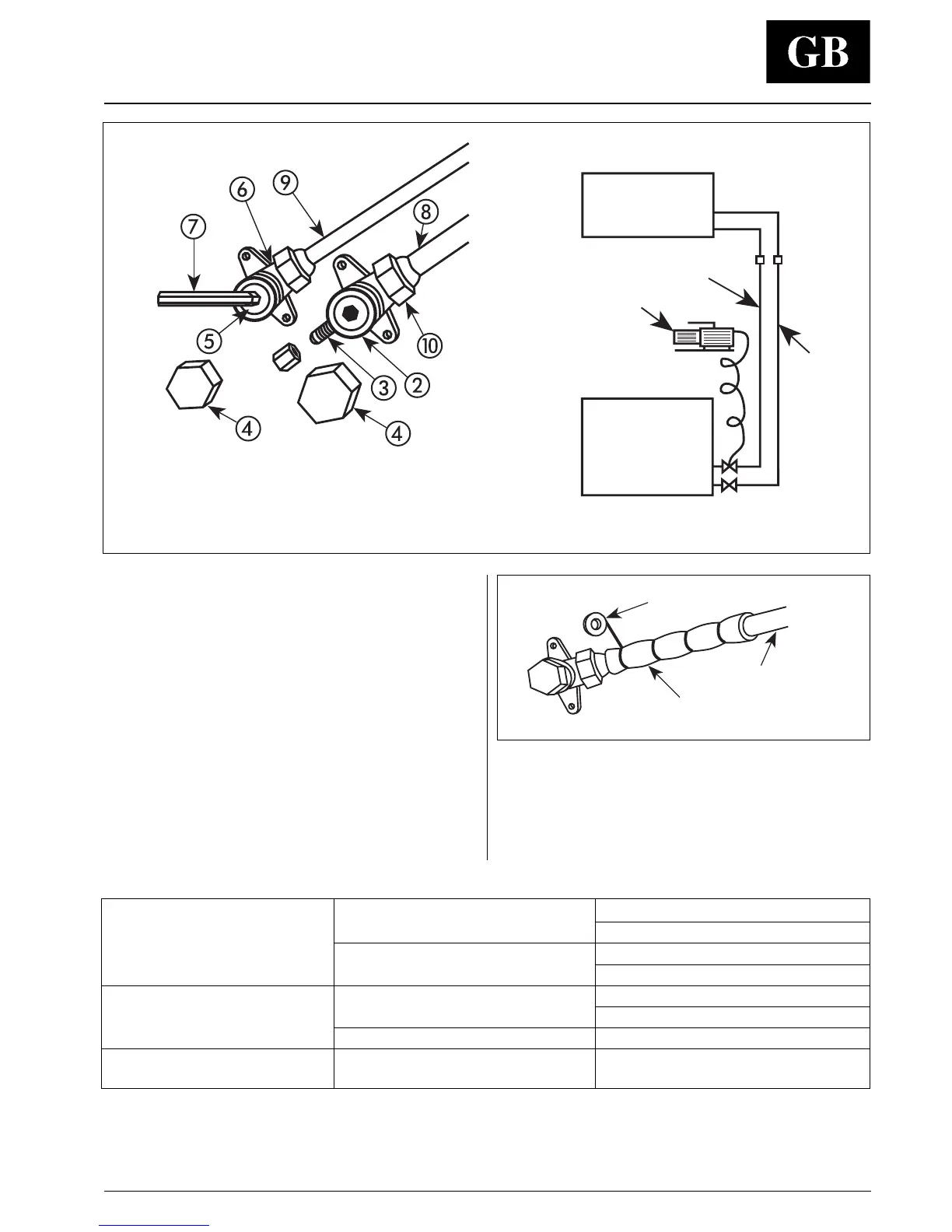

헀 Pipe

헁 Pipe insulation

헂 Fastening tape

Air purging

Use only a vacuum pump to purge air from the piping.

NEVER use the system compressor as a vacuum pump.

NEVER use the unit refrigerant gas to purge the connecting

pipes.

No additional refrigerant has been provided in the unit for this

purpose.

Remove the caps from the two and three-way valves.

Create a vacuum with a vacuum pump connected to the service

connection of the suction shut-off valve, as shown, keeping the

shut-off valves completely shut until a 50 Pa (0.5 mbar) vacuum

has been reached.

Now open the two-way valve for 3 sec., then quickly shut it to check

for possible leaks.

After the leak check, fully open the two and three-way valves.

Replace caps and check for leaks.

헀

헁

헂

Cooling (2)

Maximum conditions

outdoor temperature 43°C

indoor temperature 32°C d.b.; 23°C w.b.

Minimum conditions

outdoor temperature 15°C (4)

indoor temperature 21°C d.b.; 15°C w.b.

Heating (3)

Maximum conditions

outdoor temperature 24°C d.b.; 18°C w.b.

indoor temperature 27°C d.b.

Minimum conditions outdoor temperature –15°C d.b.; –17°C w.b.

Mains power supply Nominal single-phase voltage 230V ~ 50Hz

Operating voltage limits min. 198V – max. 264V

Table III: Operating limits

(1)

WARNING:

During heat pump operation unit will undergo several defrost cycles to

eliminate ice that might possibly collect on the outdoor unit in very low

ambient temperatures.

In these cycles, fan speed will automatically reduce and cannot be

varied until defrost cycle is completed.

Notes: 1. Data referred to the outdoor unit only.

2. According to ISO 5151.2/T1.

3. According to ISO 5151.2/High+.

4. 38GLS units are provided with head pressure control

suitable up to –15°C ambient temperature (size 07 and 09

up to –5°C).

d.b. - dry bulb w.b. - wet bulb

햿

햽

햾

햺

햹

Once all connections have been completed, check for leaks by

using a leak detector specific for HFC refrigerants.

Finally wrap the valves and pipes with anti-condensate insulation

and tighten this with tape, without exerting too much pressure on

the insulation.

Repair and cover any possible cracks in the insulation.

Fix the pipes to the wall with hooks or conduits.

Loading...

Loading...